Brown coal pipe drier

A technology of tubular drying and lignite, which is applied in the direction of non-progressive dryers, dryers, and drying solid materials, etc., can solve the problems of high degree of lignite fragmentation, affecting production efficiency, and low heat utilization efficiency, so as to save energy, Simple structure and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

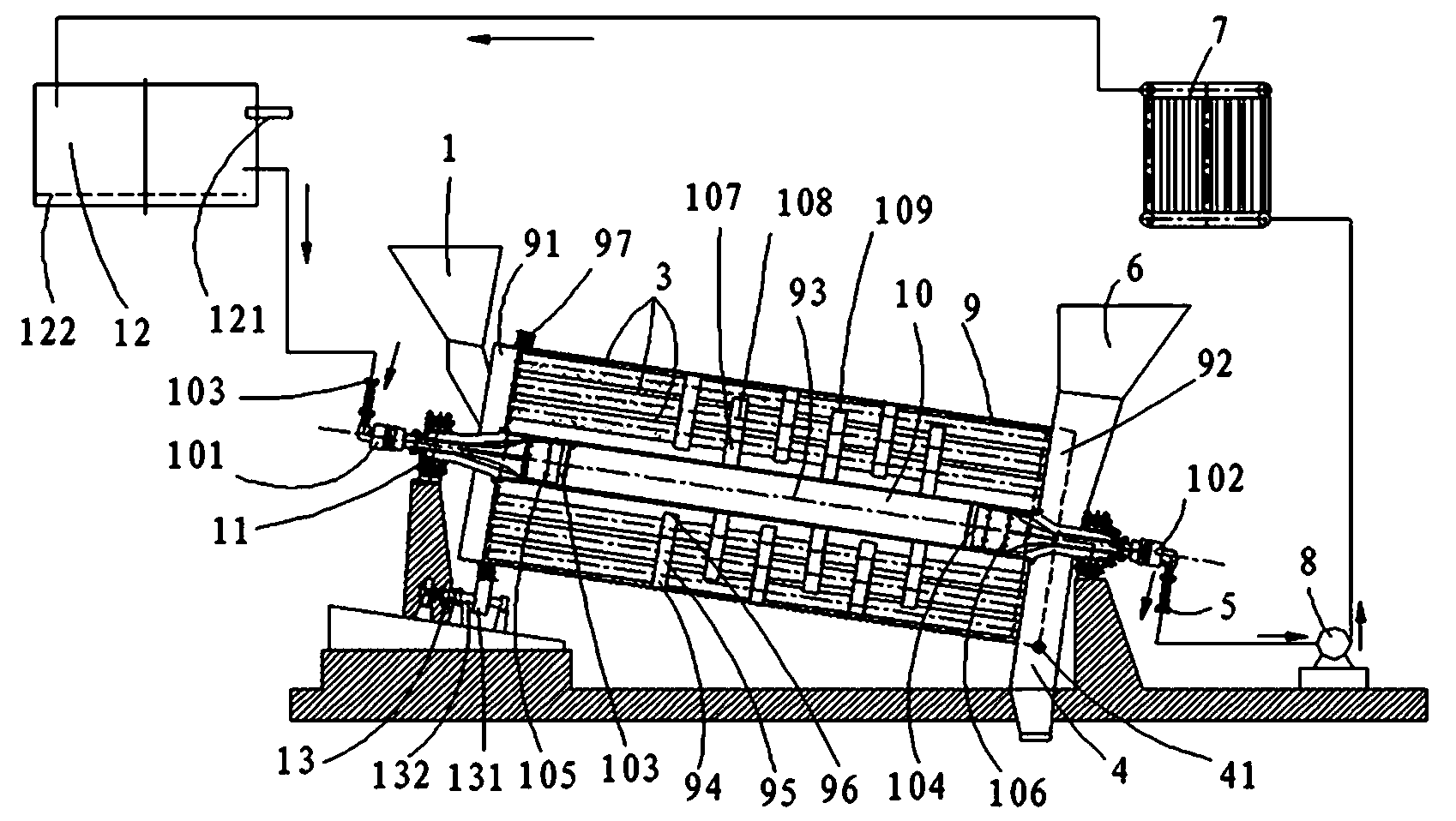

[0025] Such as figure 1 As shown, the lignite tubular dryer includes a feeding device 1, a discharging device 4, a rotating cylinder 9 with both ends sealed, and a central rotating shaft 10. The rotating cylinder 9 is connected to a power unit 13, and the rotating cylinder 9 The feed end cover 91 is connected with the feed device 1, the discharge end cover 92 of the rotating cylinder 9 is connected with the discharge device 4, the axis of the central rotating shaft 10 coincides with the axis of the rotating cylinder 9, and the outer circle of the central rotating shaft 10 is respectively It forms a sealed connection with the central hole of the feed end cover 91 and the discharge end cover 92. The two ends of the central rotating shaft 10 are respectively supported on the bearing seats ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com