Integrated LED displaying packaging module with LED chips arranged in wafers in inverted mode

A wafer-inverted, packaged module technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of reduced light output rate of LED wafers, occupying module production time, low structural mechanical strength, etc., to improve light output rate. , Speed up heat dissipation, save the effect of wire bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

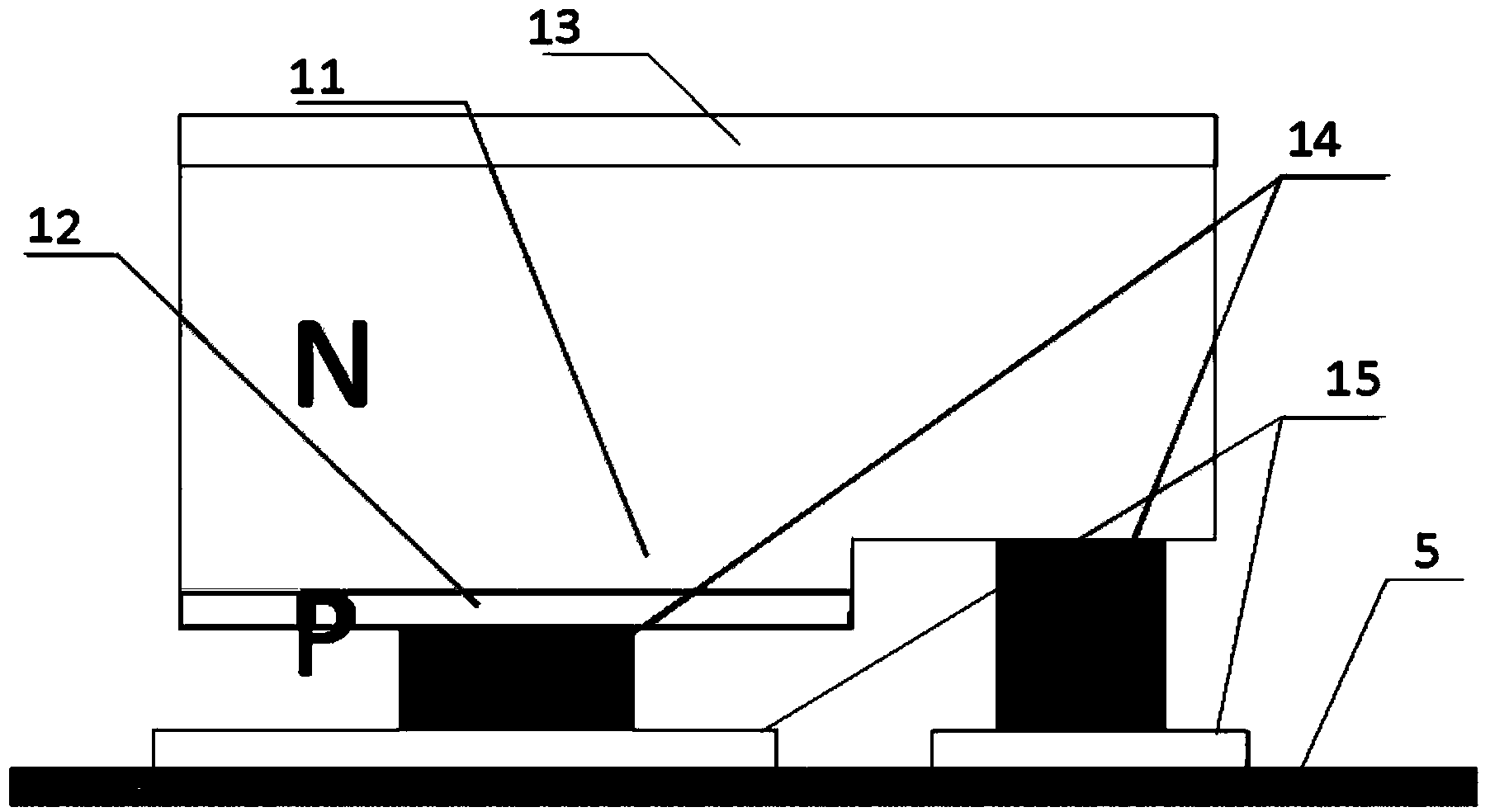

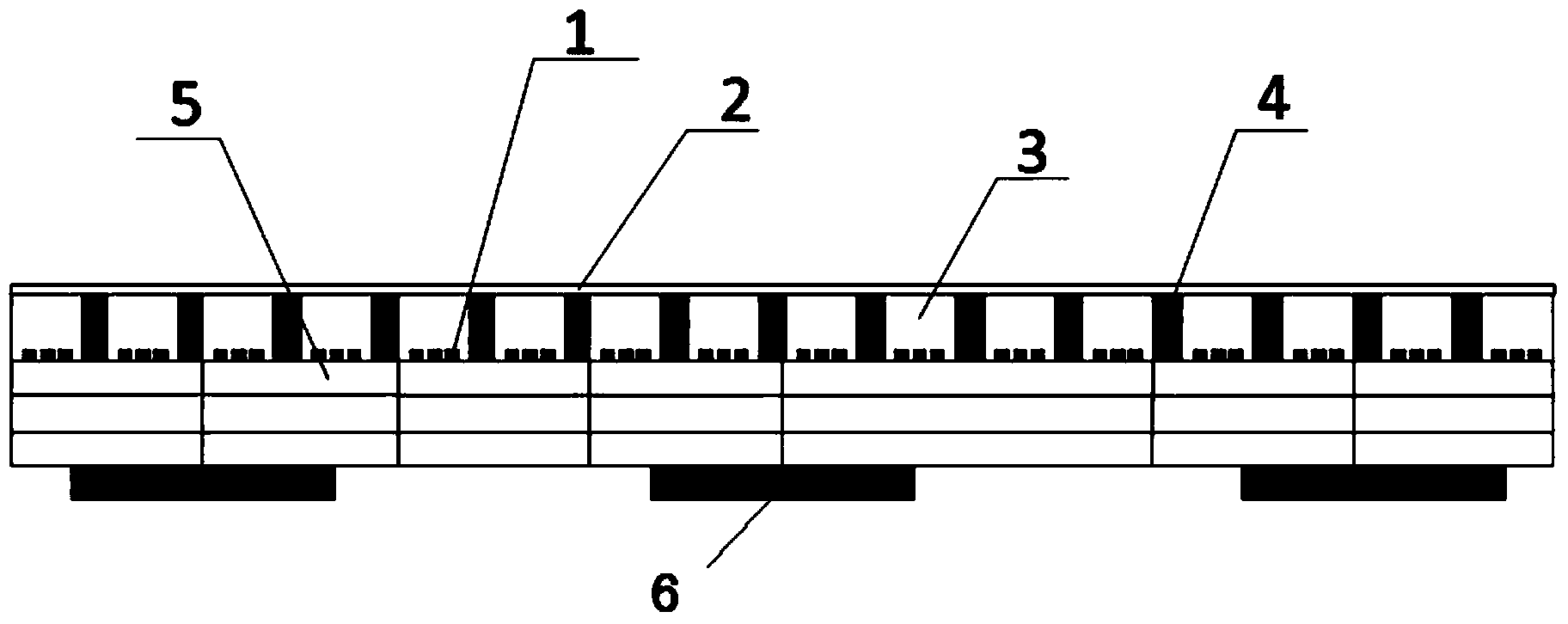

[0031] Such as figure 2 As shown, the inverted wafer integrated LED display packaging module of the present invention includes: a driver IC 6 , a driver circuit board 5 , an LED wafer 1 , a mask 4 , a transparent potting colloid 3 , and a translucent modified film 2 . The dot pitch is d=1mm, and the resolution is 64×64. The drive IC 6 is welded on the back of the drive circuit board 5, and the LED wafer 1 is fixed on the front of the drive circuit board 5; the blue and green LED chips are installed upside down, and the red LED chips are installed upright; the dimensions of the blue and green LED chips are: 8mils×8mils, the positive and negative electrodes of the blue and green LED chips are connected and fixed to the corresponding printed electrodes on the drive circuit board 5 through conductive silver glue, and the conductive silver glue required to fix each electrode is about: 0.0015mm -3 The position of the mask 4 corresponding to the LED wafer 1 has a light outlet, and ...

Embodiment 2

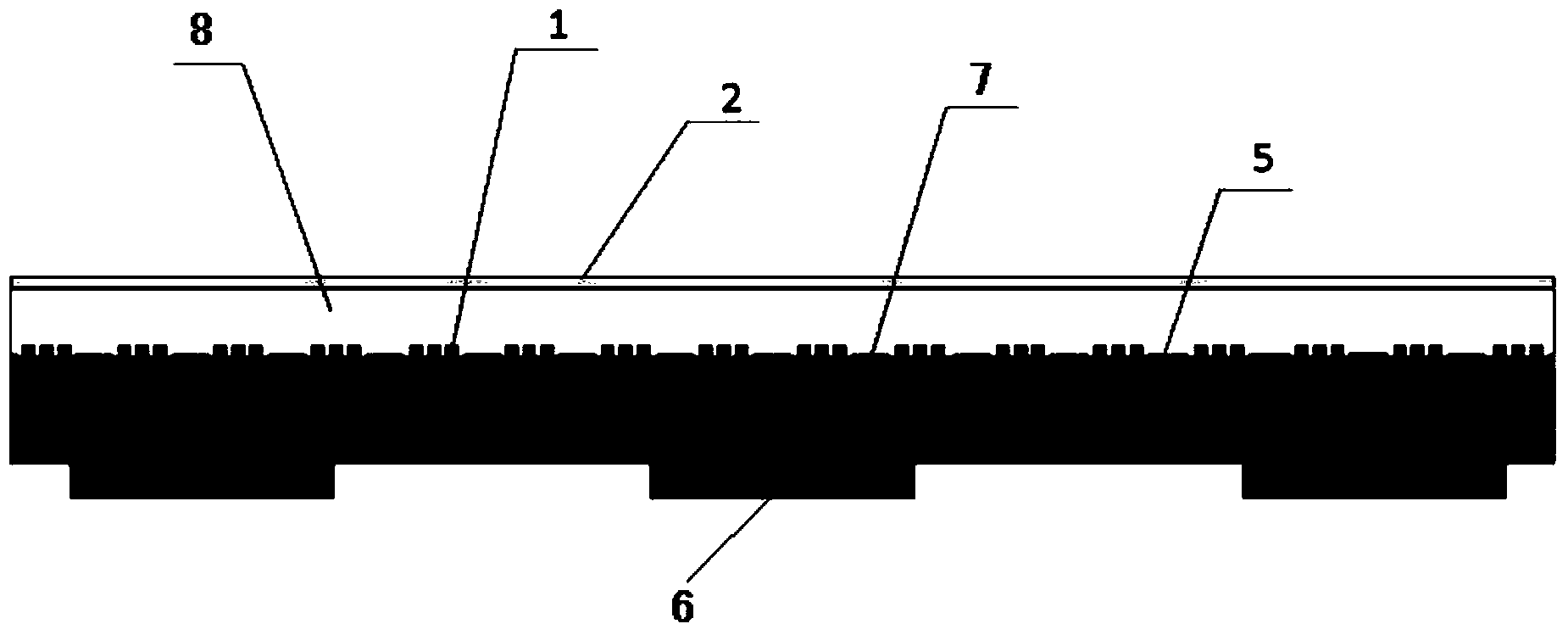

[0033] Such as image 3 As shown, the inverted wafer integrated LED display packaging module of the present invention includes: a driver IC 6 , a driver circuit board 5 , an LED wafer 1 , a black paint layer 7 , a transparent protective adhesive layer 8 , and a light-transmitting modified film 2 . The dot pitch is d=1.5mm, and the resolution is 64×64. The driver IC 6 is welded on the back of the driver circuit board 5, and the LED wafer 1 is fixed on the front of the driver circuit board 5; the blue and green LED chips are installed upside down, and the red LED chips are installed upright; the size of the blue and green LED chips is: 7mils ×12mils, the positive and negative electrodes of the blue and green LED chips are connected and fixed to the corresponding electrodes on the drive circuit board 5 through conductive silver glue, and the conductive silver glue required to fix each electrode is about: 0.003mm -3 The front of the driving circuit board 5 is sprayed with a black...

Embodiment 3

[0035] Such as image 3 As shown, the inverted wafer integrated LED display packaging module of the present invention includes: a driver IC 6 , a driver circuit board 5 , an LED wafer 1 , a black paint layer 7 , a transparent protective adhesive layer 8 , and a light-transmitting modified film 2 . The dot pitch is d=1.5mm, and the resolution is 64×64. The driver IC 6 is welded on the back of the driver circuit board 5, and the LED wafer 1 is fixed on the front of the driver circuit board 5; the blue and green LED chips are installed upside down, and the red LED chips are installed upright; the size of the blue and green LED chips is: 7mils ×12mils, the positive and negative electrodes of the blue and green LED chips are connected and fixed to the corresponding electrodes on the drive circuit board through conductive silver glue, and the conductive silver glue required to fix each electrode is about: 0.002mm -3The front of the driving circuit board 5 is sprayed with a black pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com