Multiple electrode array and manufacturing method

A technology of multi-electrode array and manufacturing method, which is applied in the field of multi-electrode array, can solve the problems of non-productization, large brain tissue damage, and difficulty in manufacturing density, and achieve easy implementation, high reliability and mechanical strength, and eliminate the need for soldering. The effect of line craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

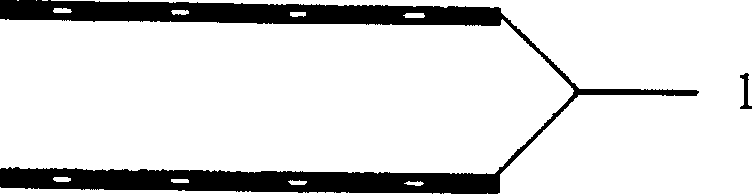

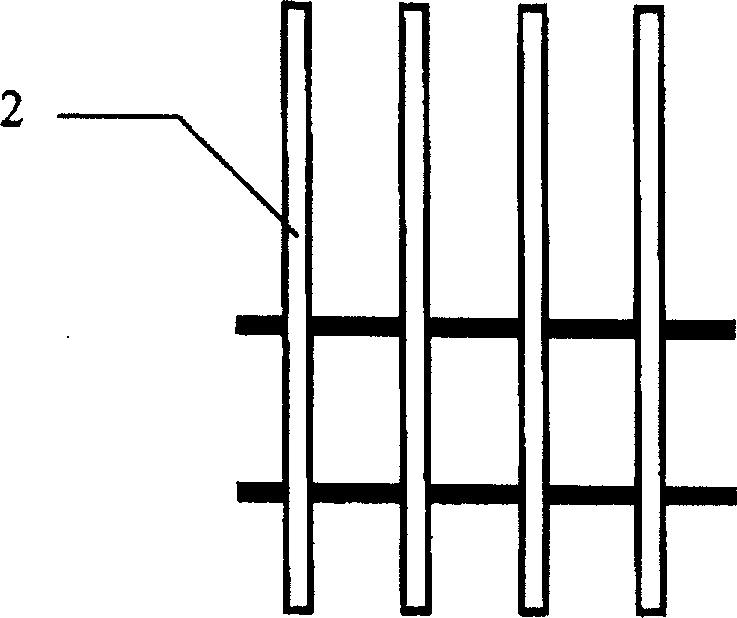

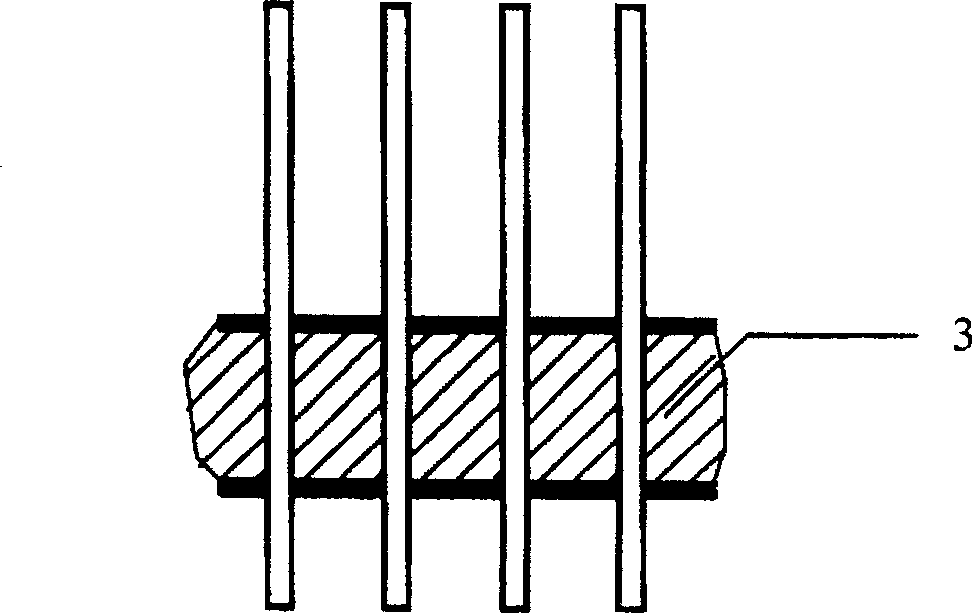

[0045] see Figure 1 (a) ~ Figure 1 (f) , Take two pieces of brass with a thickness of 0.05 mm, laser drill a 10×10 array of micro-holes with a diameter of 30 μm and a hole spacing of 200 μm. The two micro-hole array thin plates 1 are horizontally separated by 1 mm and fixed. Take the steel wire 2 with a diameter of about 27 microns, straighten it and cut it into 100 steel wires 2 of 30 mm length, and insert the steel wire 2 into the micro holes of the two micro-hole array plates 1 with the tip of about 1 mm exposed. , The rear end is exposed to an appropriate length. Put the newly prepared denture tray resin 3 into the space between the two microporous array sheets 1 immediately. After 20 minutes, the resin 3 will solidify, pull out the steel wire 2. Peel off the two microporous array sheets 1, and trim the shape of the denture block A micro-hole array 4 with a hole diameter of about 25 microns, a hole depth of 1 mm, and a 10×10 can be obtained.

[0046] Prepare one hundred single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com