A direct current energizing method

A technology of direct current and direct current power supply systems, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve problems such as line voltage loss, achieve economic benefits, and improve system output power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation will be described in detail below in conjunction with the accompanying drawings:

[0043] A method for increasing direct current energy, characterized in that: the following steps are adopted:

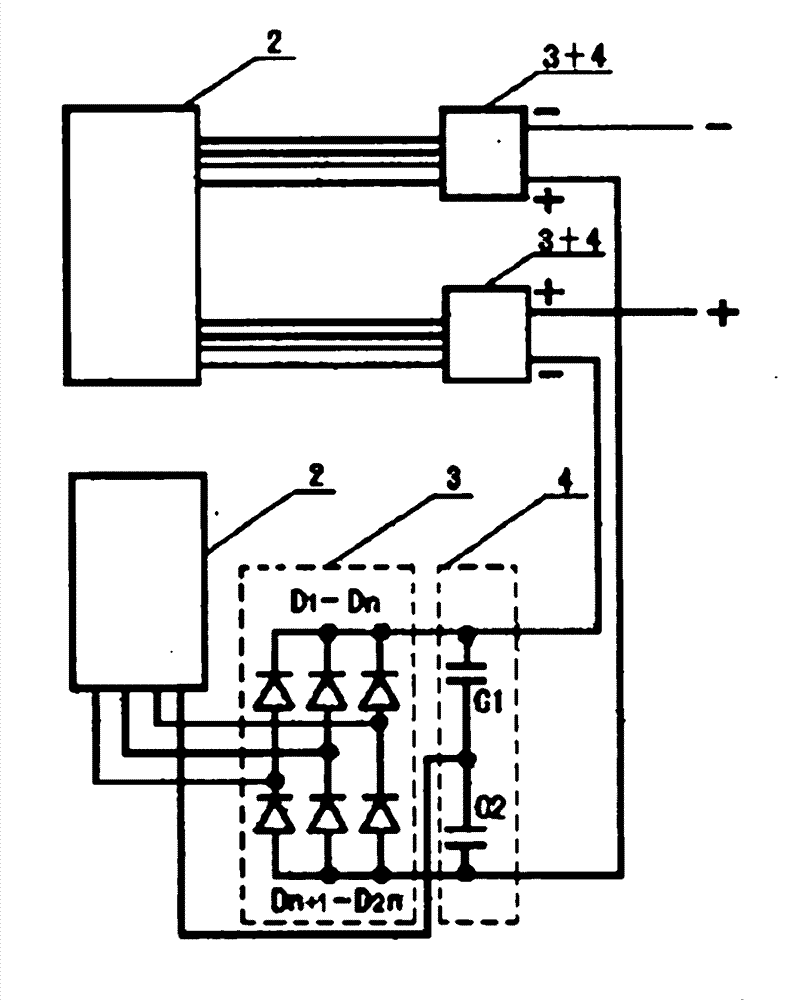

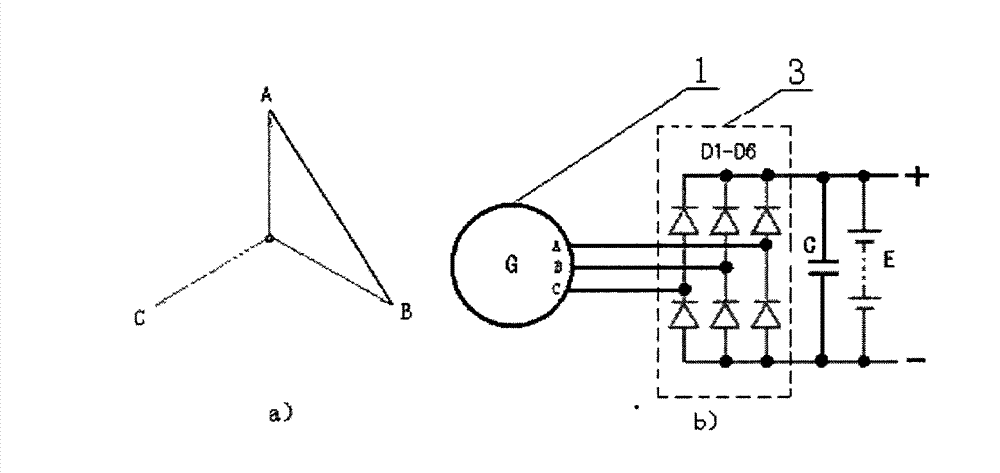

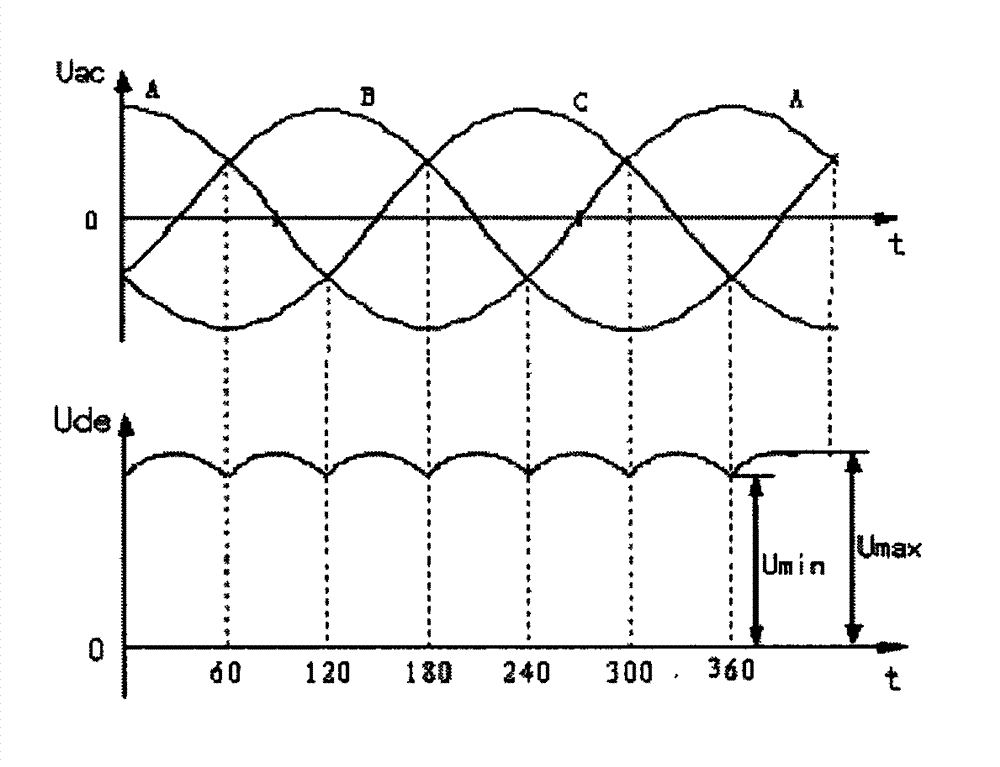

[0044] In the traditional DC power supply system composed of three-phase AC synchronous generators, and / or three-phase transformers, and three-phase rectifiers, AC synchronous generators with more than three phases and rectifiers with the same number of phases matching the AC synchronous generators are used Substitute to form an energy-saving DC power supply system.

[0045] The description is as follows: the device that we use today to convert mechanical energy into direct current widely adopts the technical route of alternating current synchronous power generation and rectification into direct current through silicon diodes, and no longer uses high-efficiency and low-cost direct current generators. The three-phase generator used is consistent with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com