Nitride semiconductor device

A nitride semiconductor and electrode technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of inability to miniaturize, limited reduction of electrode pads, and large area, etc., to achieve Effects of prevention of electromigration, suppression reduction, and on-resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

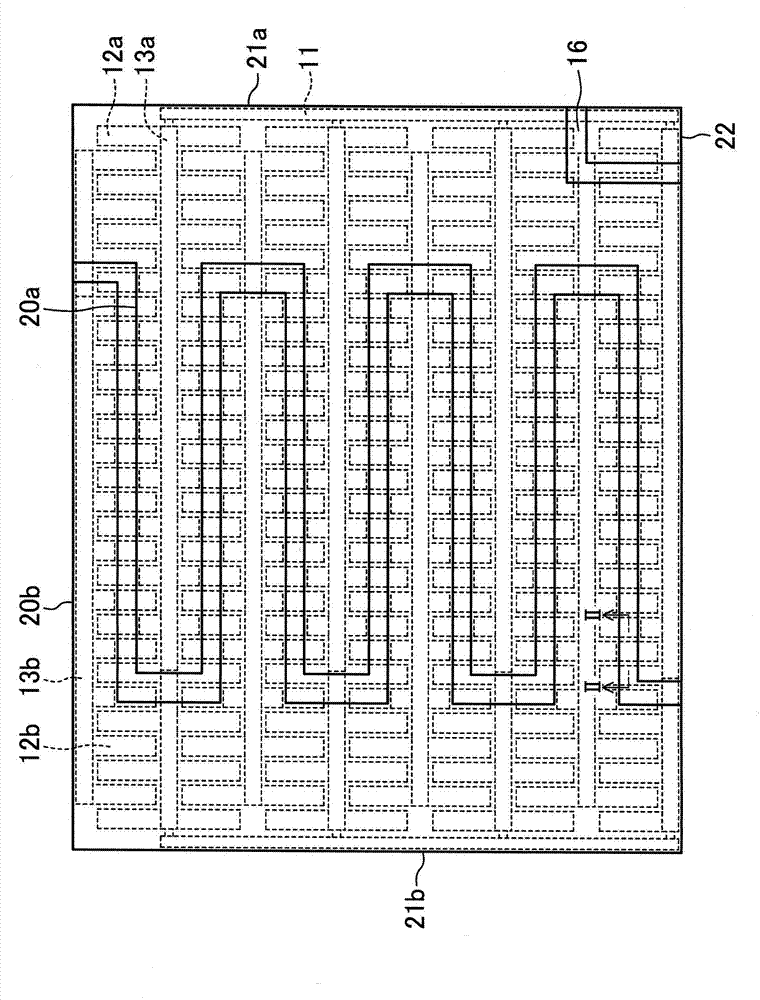

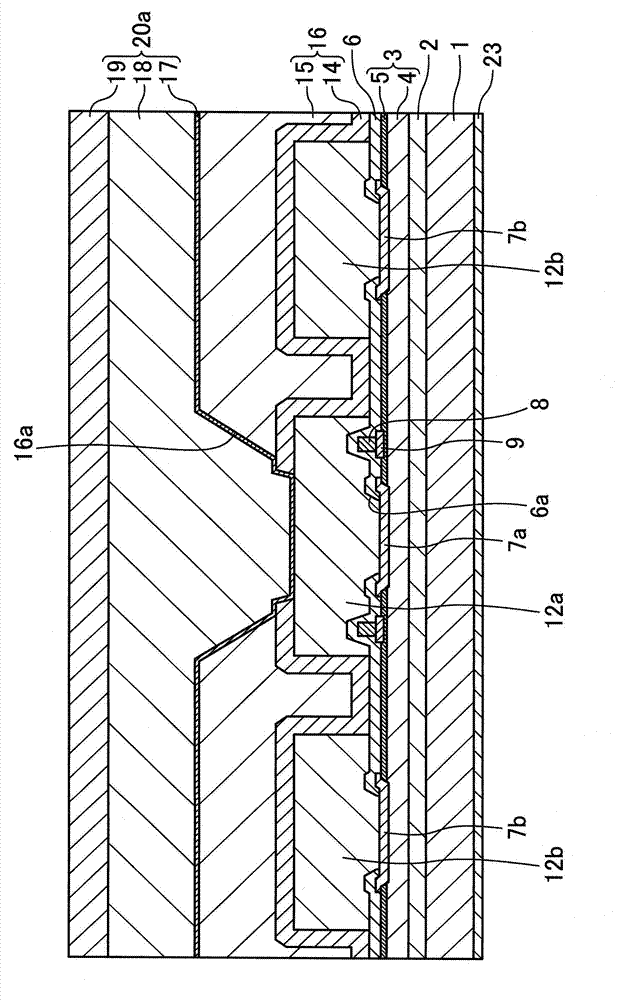

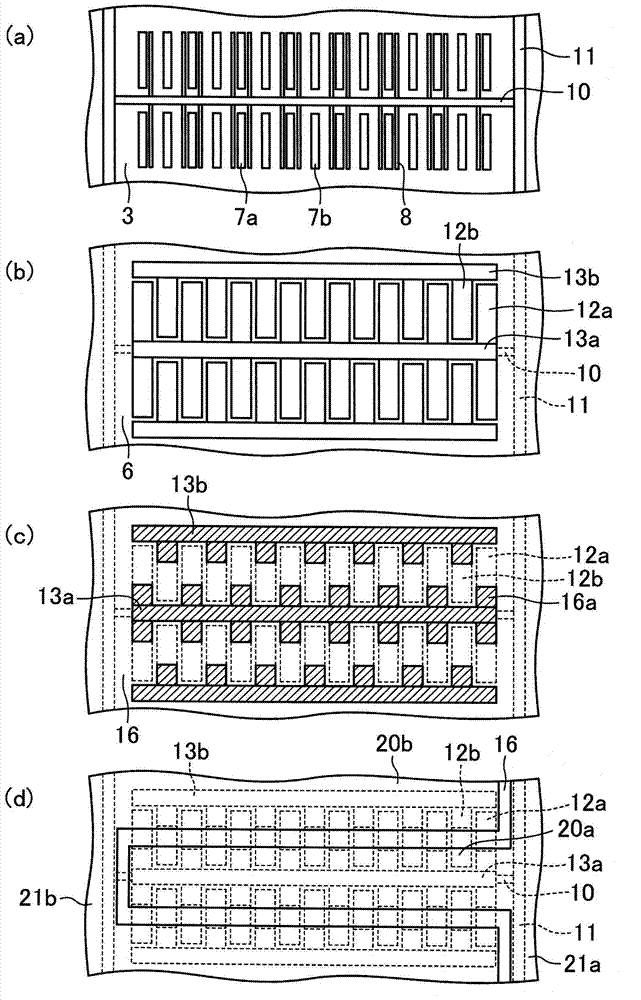

[0047] refer to Figure 1 ~ Figure 3 The nitride semiconductor device according to the first embodiment of the present invention will be described.

[0048] Such as figure 1 as well as figure 2 As shown, in the nitride semiconductor device of the first embodiment, a buffer layer 2 and a nitride semiconductor layer 3 are sequentially formed on a substrate 1 formed of, for example, silicon (Si). The nitride semiconductor layer 3 is composed of an undoped gallium nitride (GaN) layer 4 with a thickness of about 2.5 μm and an undoped aluminum gallium nitride (AlGaN) layer 5 with a thickness of about 50 nm formed thereon. A two-dimensional electron gas (2DEG) is generated in the interface region between the undoped GaN layer 4 and the undoped AlGaN layer 5 , and the 2DEG functions as a channel region.

[0049] On the nitride semiconductor layer 3 , source electrodes 7 a as first electrodes and drain electrodes 7 b as second electrodes are separated from each other and alternatel...

no. 2 approach

[0065] Below, refer to Figure 4 as well as Figure 5 A nitride semiconductor device according to a second embodiment of the present invention will be described. In the present embodiment, the same reference numerals are attached to the same components as in the first embodiment, and description thereof will be omitted, and only different parts will be described.

[0066] The nitride semiconductor device according to the second embodiment of the present invention is a double gate type nitride semiconductor device having two gate electrodes, the first gate electrode G1 electrode 38a and the second gate electrode G2 electrode 38b. Such as Figure 4 as well as Figure 5 As shown, a G1 electrode pad 52a and a G2 electrode pad 52b electrically connected to the G1 electrode 38a and the G2 electrode 38b are formed on the active region. Similarly, an S1 electrode pad 51a and an S2 electrode pad 51b electrically connected to the S1 electrode 37a as the first electrode and the S2 el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com