Coated drip irrigation pipe capable of applying common compound fertilizer

A technology of covering pipes and compound fertilizers is applied in the field of agricultural drip irrigation, which can solve the problems of short service life, easy blockage, uneven drip irrigation, etc., and achieve the effects of reducing production costs, not easy to block, and good drip irrigation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

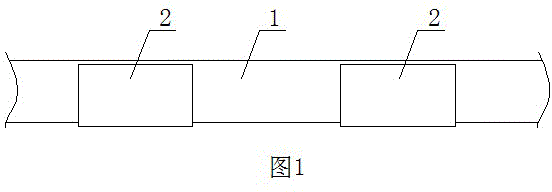

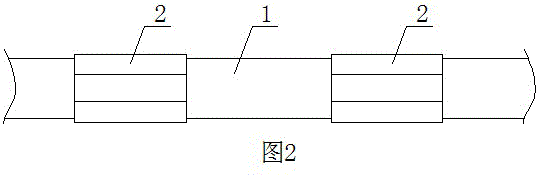

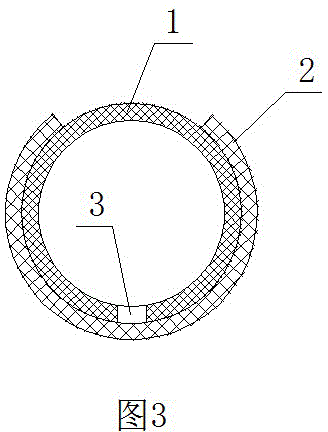

[0013] The coated drip irrigation pipe capable of applying ordinary compound fertilizer is composed of a main pipe 1 and a coated pipe 2. The coated pipe 2 and the main pipe 1 are plastic pipes of the same diameter. One side of the coated pipe 2 is cut along the axial direction. After the opening 4 is covered on the main pipe 1 by its own elasticity, at least one outlet hole 3 is made at the position covered by the covering pipe 2 of the main pipe 1; the location of the outlet hole 3 is placed opposite to the opening 4 of the covering pipe 2 On the main pipe 1 on one side, the diameter of the outlet hole 3 is 1 mm to 1.5 mm, and the length of the covering pipe is 5 cm to 15 cm.

[0014] The use process of the coated drip irrigation pipe capable of applying ordinary compound fertilizer is to first connect the main pipe 1 and the water supply pipe through a pipe joint, and then make a 1mm~1.5mm-1.5mm under the main pipe 1 according to the position of the tree root. mm diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com