Light-weight heat-insulating concrete and preparation method thereof

A lightweight thermal insulation and concrete technology, applied in the field of building materials, can solve the problems that the performance of all-light concrete cannot meet the engineering requirements, the construction process of the thermal insulation layer is complicated, etc., so as to save the construction period, improve the thermal insulation performance, and simplify the thermal insulation structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

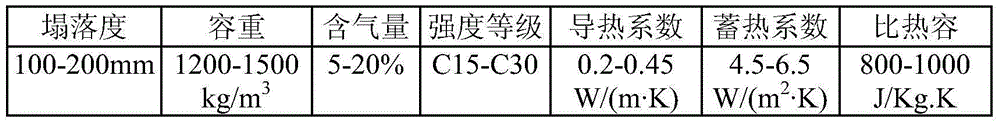

[0023] Example 1: Configure lightweight heat-insulating concrete with a bulk density of 1200

[0024] According to the total mass of each component in the lightweight heat-insulating concrete per cubic meter is 1200Kg, respectively take 350kg of cement, 12kg of microsilica fume, 32kg of fly ash, 172kg of sand, 220kg of pottery sand, 274kg of ceramsite, 5kg of admixture, and 135kg of water , Pour it into the mixer and mix for 2-4 minutes to make lightweight heat-insulating concrete. After the lightweight heat-insulating concrete is hardened, its strength grade is C15, its thermal conductivity is 0.2W / (m·K), and its heat storage coefficient is 4.5W / (m 2 · K).

Embodiment 2

[0025] Example 2: Configure lightweight heat-insulating concrete with a bulk density of 1350

[0026] According to the total weight of each component in each cubic meter of lightweight heat-insulating concrete is 1350Kg, respectively take 386kg of cement, 14kg of microsilica fume, 38kg of fly ash, 174kg of sand, 245kg of pottery sand, 353kg of ceramsite, 5kg of admixture, and 135kg of water , Pour it into the mixer and mix for 2-4 minutes to make lightweight heat-insulating concrete. After the lightweight heat-insulating concrete is hardened, its strength grade is C25, its thermal conductivity is 0.4W / (m·K), and its heat storage coefficient is 5.5W / (m 2 · K).

Embodiment 3

[0027] Example 3: Configure lightweight heat-insulating concrete with a bulk density of 1500

[0028] According to the total weight of each component in each cubic meter of lightweight heat-insulating concrete is 1500Kg, respectively take 410kg of cement, 30kg of microsilica fume, 50kg of fly ash, 220kg of sand, 300kg of pottery sand, 335kg of ceramsite, 10kg of admixture, and 145kg of water , Pour it into the mixer and mix for 2-4 minutes to make lightweight heat-insulating concrete. After hardening, the lightweight heat-insulating concrete has a strength grade of C30, a thermal conductivity of 0.45W / (m·K), and a heat storage coefficient of 6.5 W / (m 2 · K).

[0029] The above-mentioned lightweight heat-insulating concrete fully meets the engineering requirements of ordinary buildings, and its performance parameters compared with existing conventional building materials are shown in Table 2:

[0030] name DensityKg / m 3 Thermal conductivity W / (m.K) Heat storage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com