An embedded prefabricated concrete exterior wall panel and its hoisting method

A technology of prefabricated concrete and hoisting method, which is applied in the direction of building components, buildings, building structures, etc. It can solve the problems of losing the superiority of concrete exterior wall panels, not considering the replacement of exterior wall panels, and difficult replacement of building exterior wall panels. , to achieve the effect of improving thermal insulation performance and anti-leakage effect, reducing the difficulty of hoisting and shelving, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

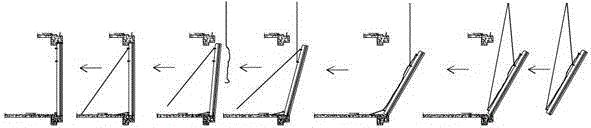

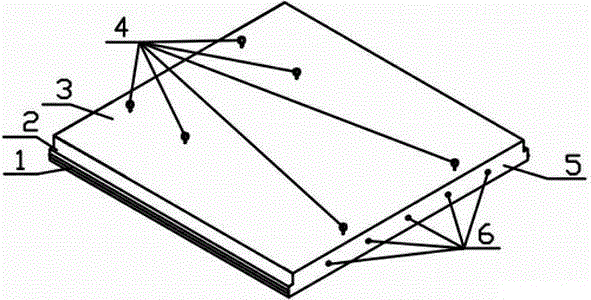

[0031] Such as figure 1As shown, the prefabricated concrete exterior wall panel of the present invention is used to be installed on the building floor to form a body of wall. It can be designed into a corresponding size according to the actual size, and can be directly arranged between two columns to form a body of wall, or can be formed by Several prefabricated concrete exterior wall panels are connected to each other, and it includes an exterior wall panel body 3. The two sides of the exterior wall panel body 3 are set in a stepped structure. The width of the two is greater than the width of the inner surface, and the difference between the two forms a step 2, and a rubber strip 1 is provided on the relatively wide outer surface. and other components form airtight joints, which is convenient f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com