Side-groove sliding clamp type stone dry-hanging structure

A stone dry-hanging, groove-sliding card-type technology, which is applied in building construction, covering/lining, construction, etc., can solve problems such as short service life, easy aging of corner glue, and stone falling off, so as to improve standardization and productization The effect of shortening the stone installation period and avoiding the hidden danger of aging and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

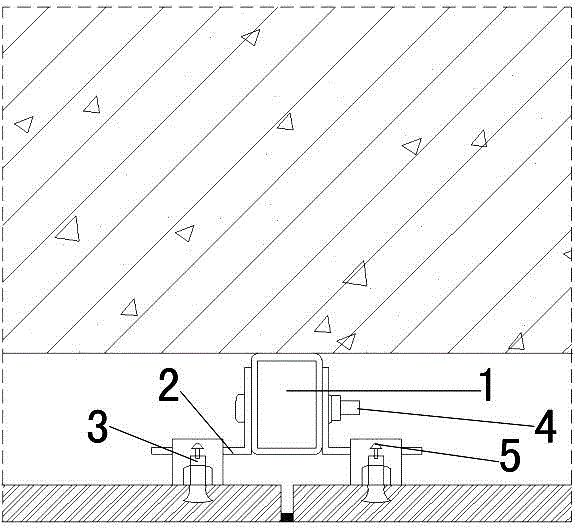

[0019] Example: such as figure 1 Shown: a side groove sliding card type stone dry hanging structure, which includes stone, square steel keel 1, sliding card type hanger 2, integrated hanger 3.

[0020] The square steel keel 1 is fixed on the wall, and the sliding card type pendant 2 is fixed on both sides of the square steel keel 1, connected by bolts 4, and the sliding card type pendant 2 is L-shaped. There are side grooves 6 on the upper and lower sides of the back of the stone, and the integrated pendant 3 includes a U-shaped aluminum part and a T-shaped stone planting part, and the stone planting part is at the bottom of the U-shaped groove of the U-shaped aluminum part. The one-piece pendant 3 is embedded in the side groove 6 , and the one-piece pendant 3 is fixed on the sliding card type pendant 2 through the adjusting screw 5 .

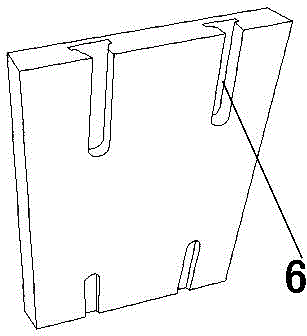

[0021] Such as figure 2 As shown, change the traditional method of slotting on the back of the stone, and adopt a new way of opening side s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com