Method and system for detecting wall shape variation and building

A change detection and wall technology, applied in the field of safety detection, can solve problems such as the difficulty of early warning of hidden dangers of deformation, and achieve the effect of realizing building safety early warning, reducing structural damage and reducing losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0061] In the embodiment of the present invention, the axial strain sensitivity formula is:

[0062] (Δλ / λ)=(1–P)C; where λ is the center wavelength of the fiber grating, C is the dielectric constant, and -P is the stress.

[0063] And the central wavelength of the fiber Bragg grating λ=2nΛ; wherein, n is the effective refractive index, and Λ is the period of the fiber Bragg grating.

[0064] Since the axial stress and the tensile strength are the relationship between the action force and the reaction force, the axial stress-P of each test point can be calculated according to the axial strain sensitivity formula and the derived wavelength change Δλ, so as to obtain the of tensile strength.

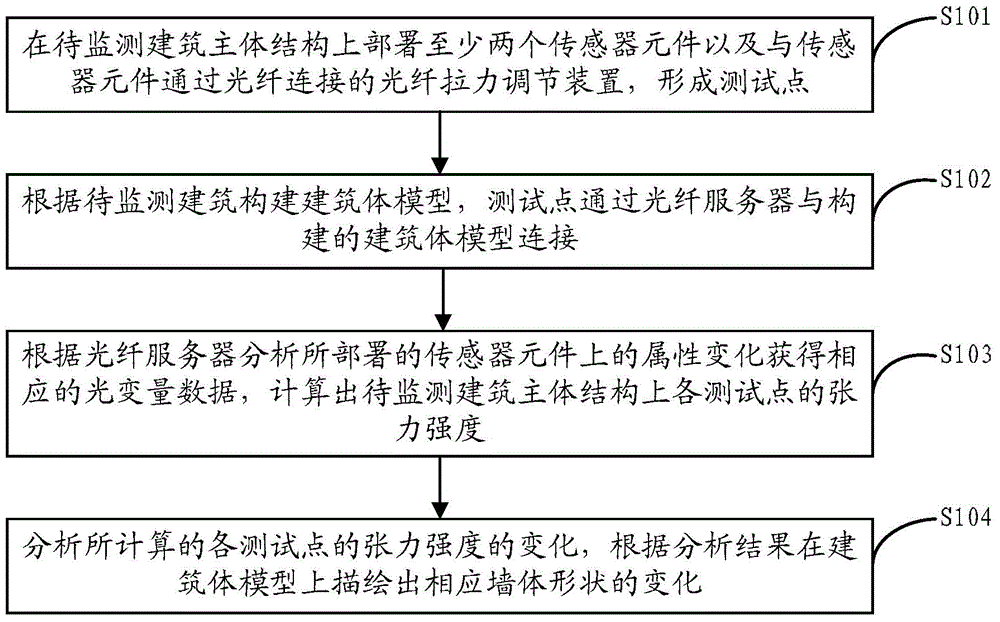

[0065] Figure 6 Shown is a schematic structural diagram of the wall shape change detection system 1 of the present invention, which includes a deployment module 11 , a model building module 12 , a calculation module 13 and an analysis module 14 .

[0066] The deployment module 11 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com