Device and method for processing peak voltage of winch frequency conversion speed adjusting device

A technology of variable frequency speed regulation and peak voltage, applied in the direction of electrical components, AC motor control, irreversible AC power input conversion to DC power output, etc., can solve problems such as coil voltage impact and motor failure, and reduce overshoot voltage , prolong life, reduce the effect of change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with specific embodiment, further illustrate the present invention.

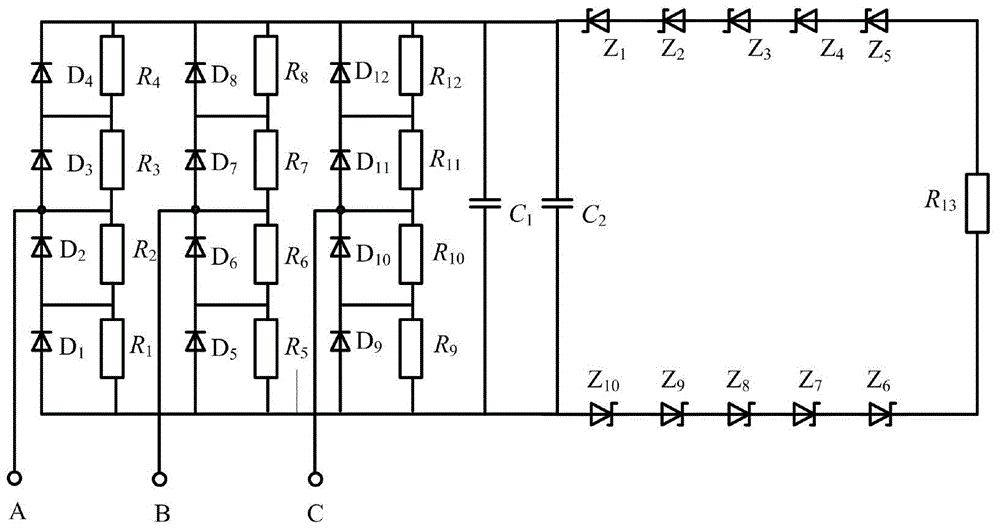

[0016] It can be seen from the figure that a device for controlling the peak voltage of the frequency conversion speed regulating device of the winch is characterized in that it includes a diode D 1 -D 12 , Resistive element R 1 -R 13 , capacitance C 1 -C 2 , Zener tube Z 1 -Z 10 .

[0017] The diode D 1 -D 4 respectively with resistor R 1 -R 4 Parallel, then series to form A phase, D 5 -D 8 respectively with resistor R 5 -R 8 Parallel, then series to form B phase, D 9 -D 12 respectively with resistor R 9 -R 12 They are connected in parallel and then connected in series to form phase C, thus forming a three-phase rectification.

[0018] R 1 , R 5 , R 9 connected together at the upper end and then with C 1 、C 2 One end connected in parallel, R 4 , R 8 , R 12 The lower ends are connected together and then with C 1 、C 2 The other end of the parallel conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com