Actinic ray curable inkjet ink and image recording method using same

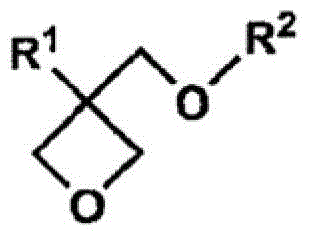

一种光化射线、固化型的技术,应用在复制/标记方法、油墨、应用等方向,能够解决溶解性低、射出性低等问题,达到高牢固性、高射出性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0209] 1) Preparation of Pigment Dispersion 1 (M: Magenta)

[0210] The following dispersant, actinic ray-curable compound, and polymerization inhibitor were put into a stainless steel beaker, heated on a hot plate at 65° C., and dissolved under heating and stirring for 1 hour. After cooling the obtained solution to room temperature, 21 parts by mass of the following magenta pigment 1 was added, put into a glass bottle together with 200 g of zirconia beads with a diameter of 0.5 mm, sealed, and dispersed with a paint shaker for 8 hours. Thereafter, the zirconia beads were removed to prepare Pigment Dispersion Liquid 1 having the following composition.

[0211] [Composition of Pigment Dispersion Liquid 1]

[0212] Dispersant: AJISPER PB824 (manufactured by Ajinomoto Fine-Techno Co., Ltd.) 9 parts by mass

[0213] Actinic ray curable compound: 70 parts by mass of APG-200 (tripropylene glycol diacrylate, manufactured by Shin-Nakamura Chemical Co., Ltd.)

[0214] Inhibitor: Irg...

Embodiment 2~8

[0235] Except having changed to the ink composition shown in Table 1, it carried out similarly to Example 1, and prepared the ink.

Embodiment 9~16

[0237] Except having changed to the ink composition shown in Table 2, it carried out similarly to Example 1, and prepared the ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com