Improved multi-side contact electronic building block

An electronic building block, surface contact technology, applied in toys, instruments, entertainment and other directions, can solve the practical and interesting bottlenecks of electronic building blocks, unable to create a splicing method, unable to splicing out graphics and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

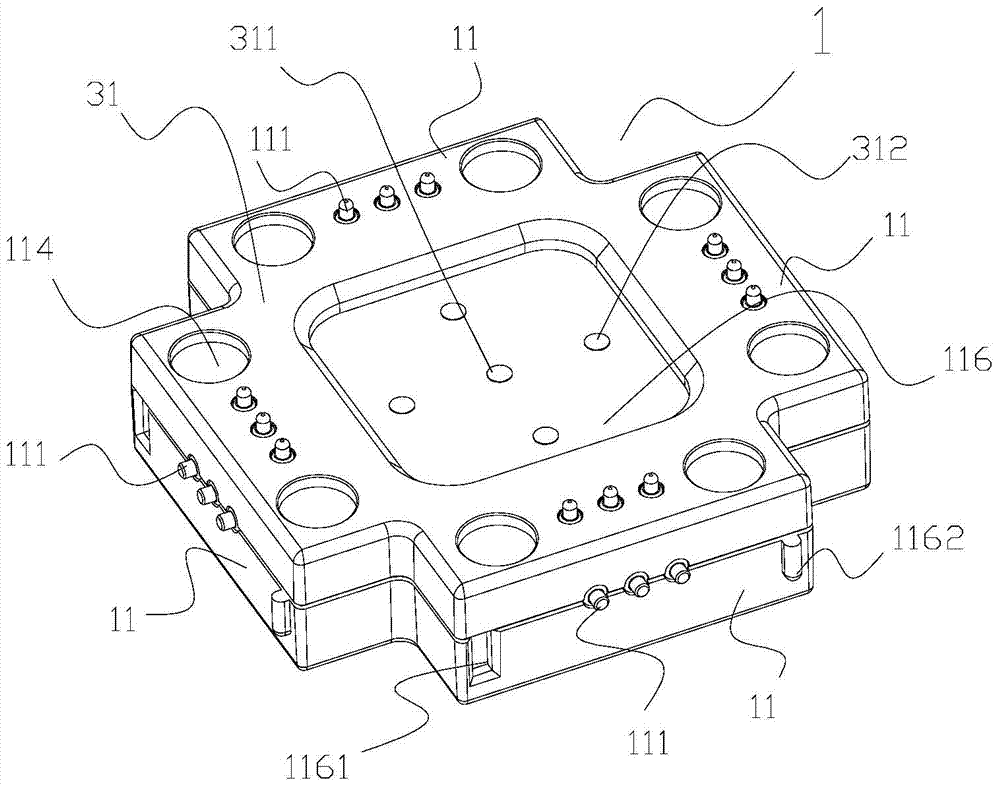

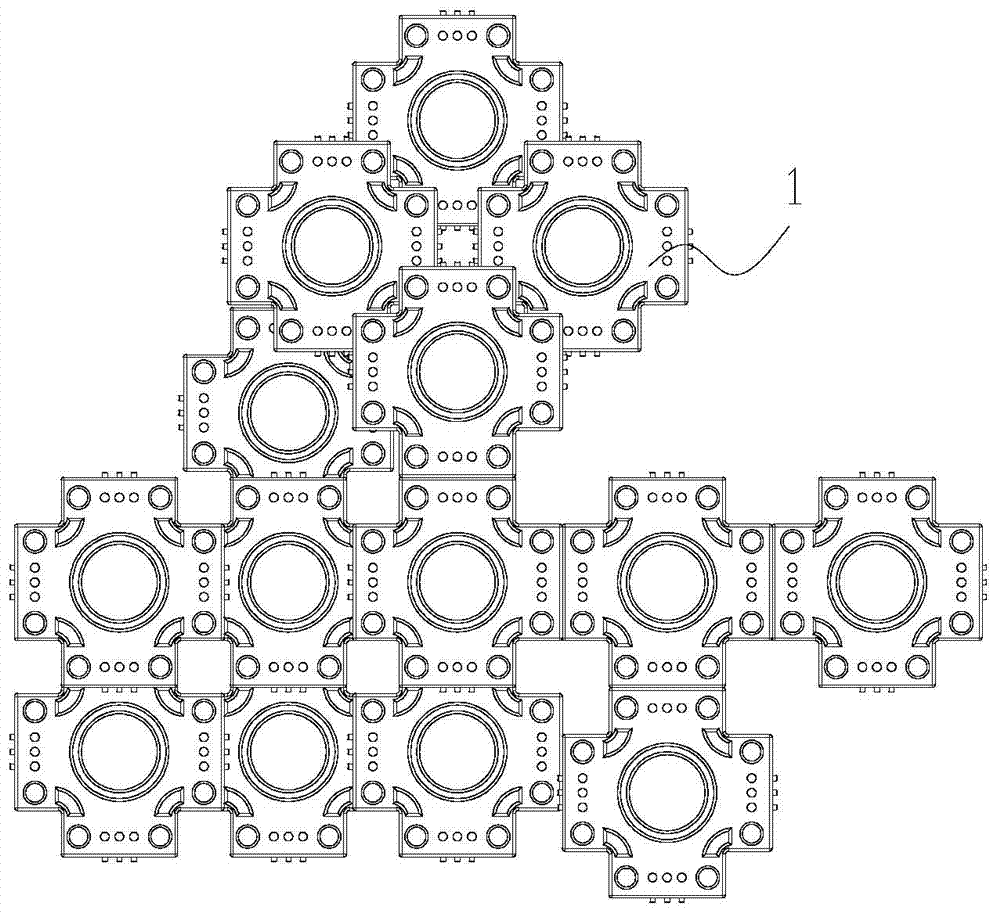

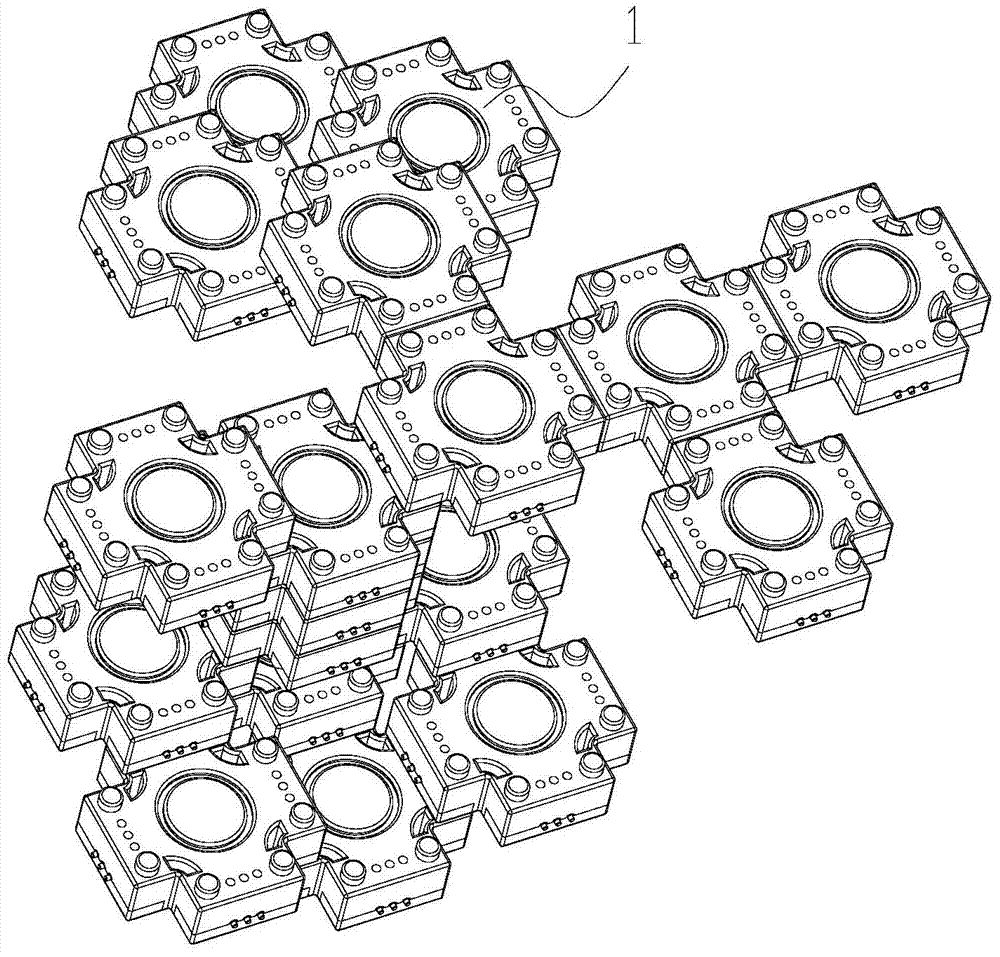

[0035] Embodiment one, such as Figure 5 shown.

[0036] In this embodiment, inner cavities 1121 are provided at both ends of the splicing boss 11 ; The inner cavity 1121 is also provided with a positioning post (not necessary) that matches the ring of the annular magnet 1120, and the annular magnet 1120 can rotate freely around the axial direction; after the annular magnet 1120 is radially magnetized The magnetism on its surface is an S-N relationship. When the two faces of the two blocks are close together, as if the side is an N-S pole, the ring-shaped magnet 1120 is mutually repulsive. At this time, the ring-shaped magnet 1120 will be in the inner cavity. 1121 internal rotation, self-adjust to the position where the magnetic poles attract each other.

Embodiment 2

[0037]Embodiment two, such as Figure 7 shown.

[0038] In this embodiment, inner cavities 1121 are provided at both ends of the splicing boss 11 ; the magnetic attraction assembly includes radially magnetized magnets movable in the inner cavities, and the magnets are spherical magnets 1123 . The spherical magnet 1123 can rotate freely; after the radial magnetization of the spherical magnet 1123, the magnetism on its surface is an S-N relationship. At this time, the spherical magnet 1123 will rotate in the inner cavity 1121 and adjust itself to a position where the magnetic poles attract each other.

Embodiment 3

[0039] Embodiment three, such as Figure 8 shown.

[0040] In this embodiment, inner cavities 1121 are provided at both ends of the splicing boss 11; Cylindrical magnet 1124 can rotate freely around the axial direction; the magnetism on the surface of cylindrical magnet 1124 after radial magnetization is S-N relationship. The magnets 1124 are mutually repulsive. At this time, the cylindrical magnet 1124 will rotate in the inner cavity 1121 and adjust itself to a position where the magnetic poles attract each other.

[0041] combine Figure 9 and 10 as well as Figure 11 and 12 , explain in detail the structure of the electrical connector in the specific embodiment. The electrical connector 111 is at least one connection contact on the outer side and the upper end surface of the splicing boss 11, and in a preferred embodiment, it is three connection contacts, and the connection contacts are spring probes or shrapnel; The connecting piece 111 is at least one contact end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com