Workpiece surface wiping device and workpiece surface wiping method

A workpiece surface and workpiece technology, applied in the field of workpiece surface wiping devices, can solve the problems of low efficiency, poor cleaning effect, and high cost of ultrasonic cleaning equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

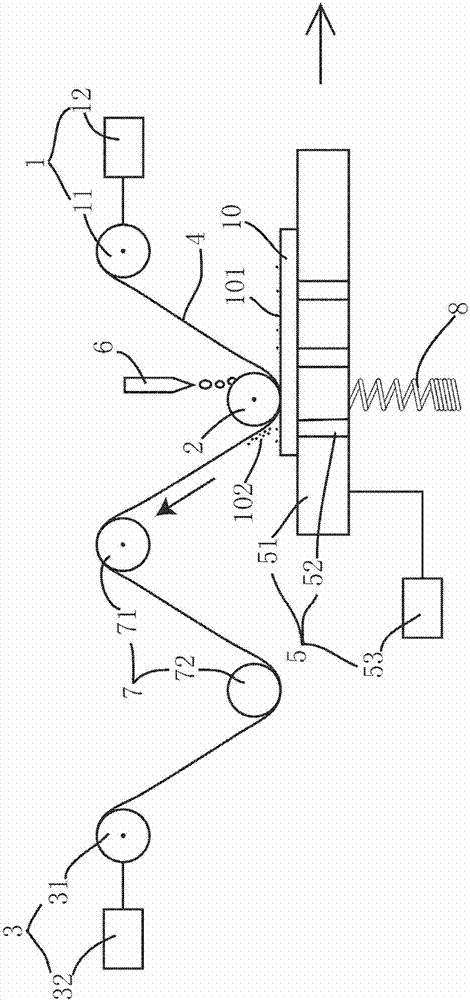

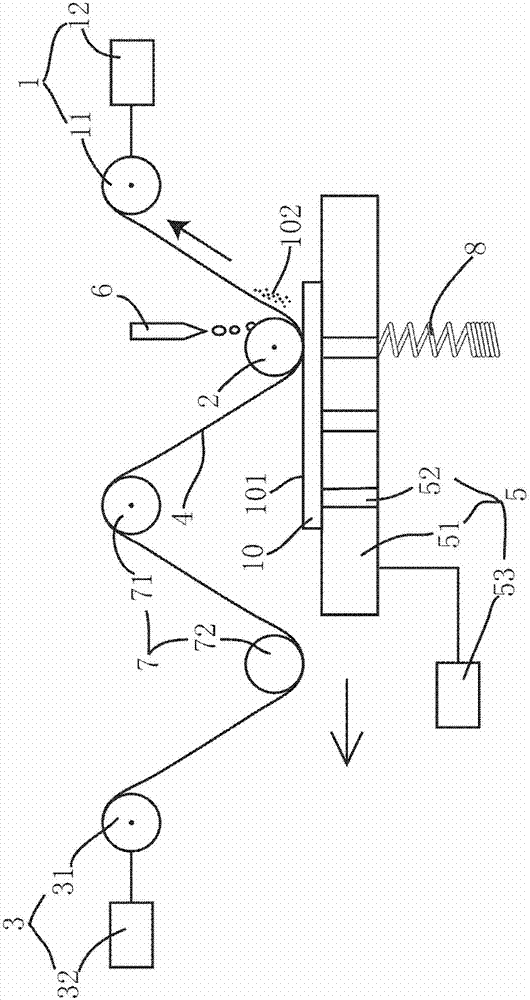

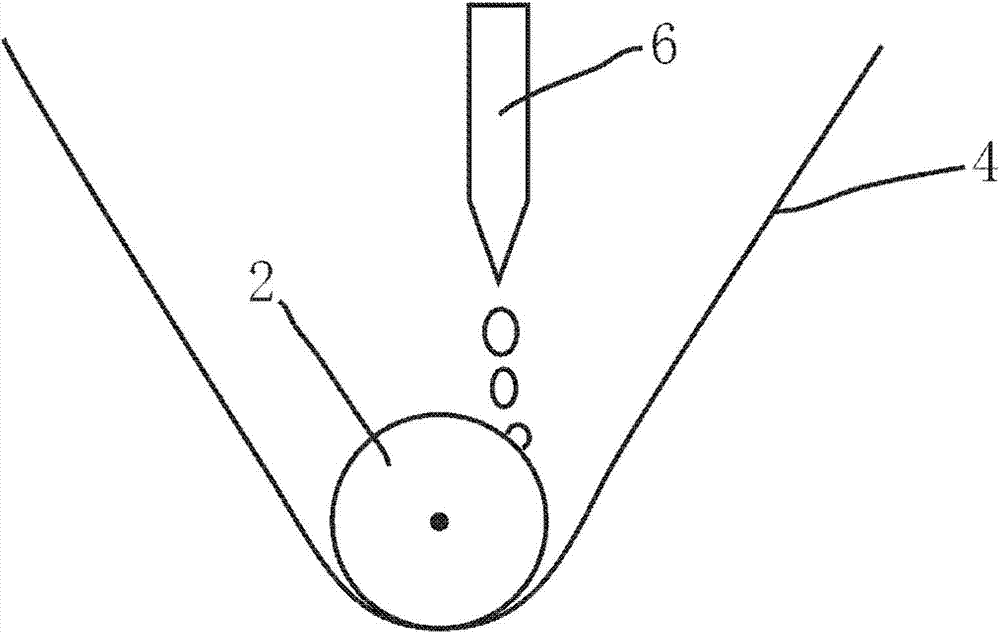

[0090] see figure 1 , figure 2 , image 3 and Figure 5 , in a specific embodiment of the present invention, the workpiece surface wiping device of the present invention includes an unwinding mechanism 1, a pressing roller 2, a winding mechanism 3, a flexible cleaning object 4 and a workpiece fixing mechanism 5, and the pressing roller 2 is located at the The downstream of the unwinding mechanism 1 is arranged axially parallel to the unwinding mechanism 1; the winding mechanism 3 is located downstream of the pressing roller 2 and arranged axially parallel to the pressing roller 2; the flexible cleaning One end of the object 4 is wound on the unwinding mechanism 1, and the other end of the flexible cleaning object 4 is wound on the winding mechanism 3 after passing through the pressing roller 2; the workpiece fixing mechanism 5 is used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com