Sand mold and sand core inner movable block drafting device

A technology for sand cores and sand molds, which is applied in the field of sand molds and loose block drawing devices inside sand cores. It can solve the problems of demanding mold drawing directions, low work efficiency, and large draft force, and achieves easy manual operation and high production efficiency. , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

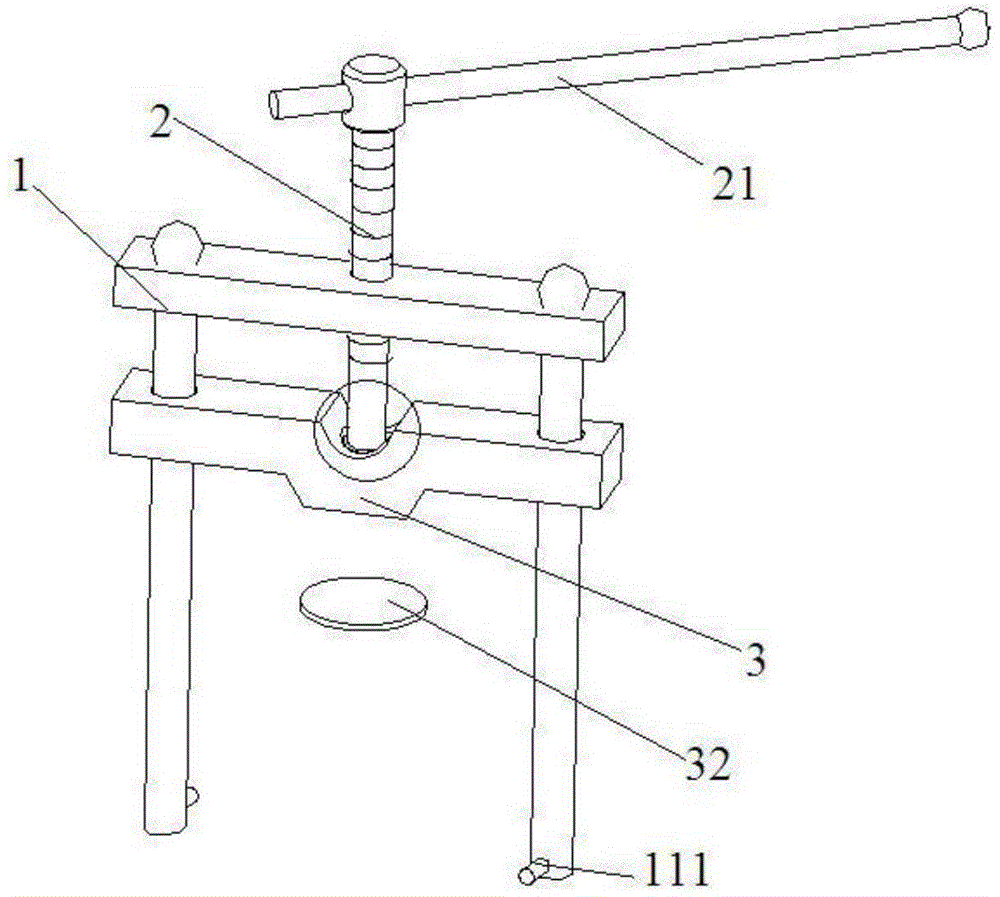

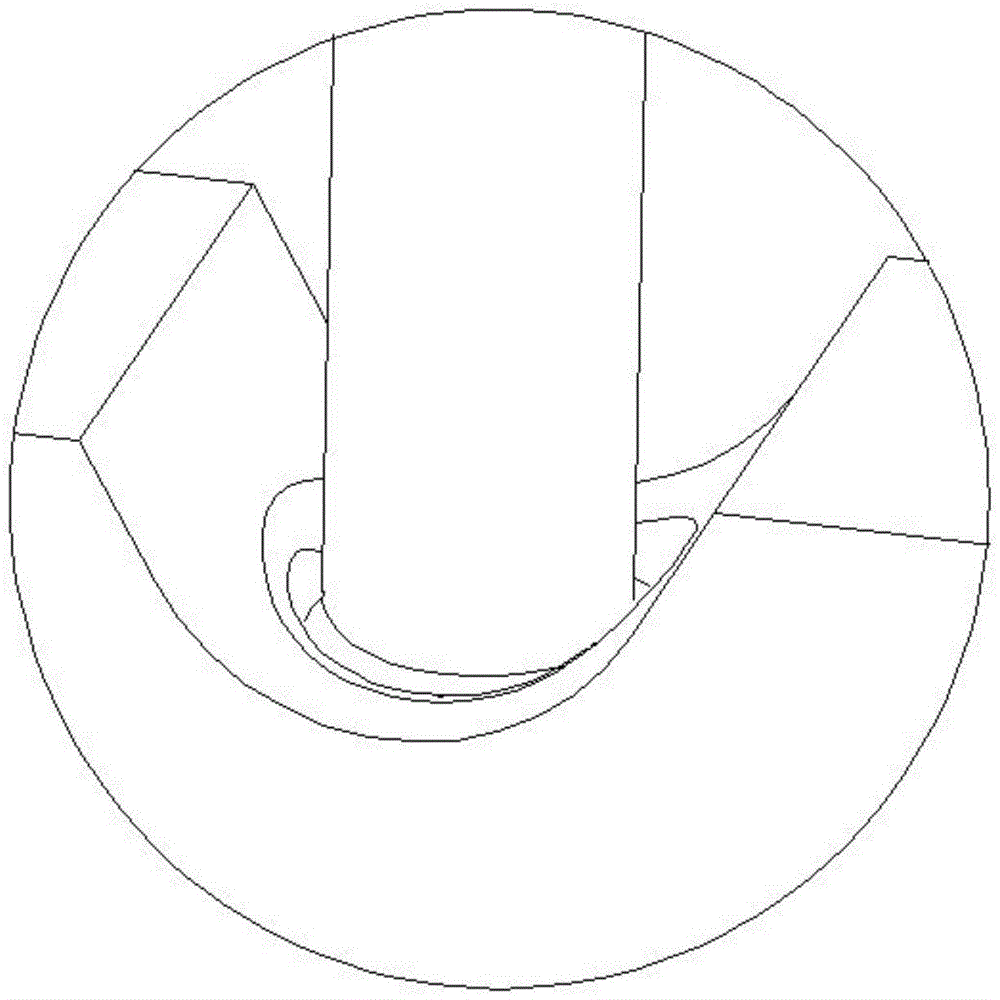

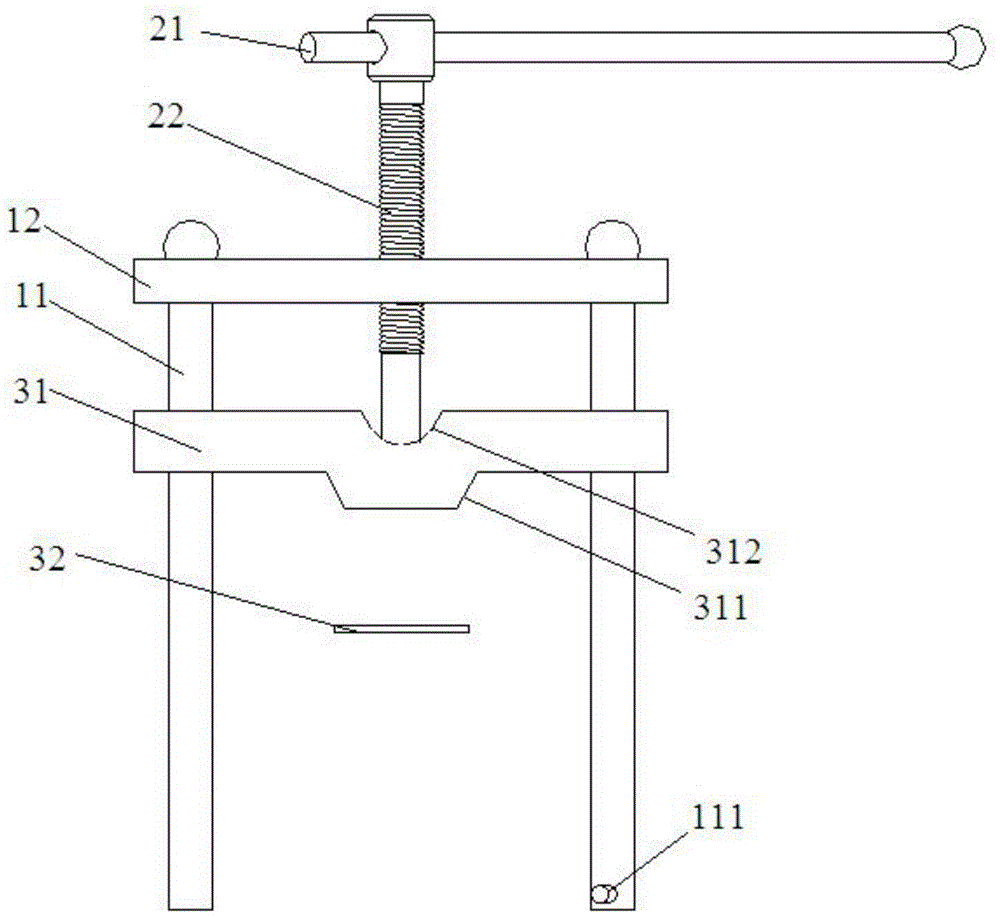

[0036] Embodiment 1 The sand mold and sand core internal movable block drawing device described in the present invention includes a support frame 1, a lever rotation mechanism 2, and a slider lifting mechanism 3. The support frame 1 includes a guide rod 11 and has an internal thread The support plate 12 of through hole, described support plate 12 is fixed on the top of described guide bar 11; Described lever rotation mechanism 2 comprises manual handle 21, rotating screw rod 22, and described manual handle 21 is installed on The upper end of the rotating screw 22, the external thread of the threaded section of the rotating screw 22 matches the internal thread of the support plate 12; the slider lifting mechanism 3 includes a slider 31 sleeved on the guide rod 11, The pressure regulating device 32 is used to be placed between the slide block and the sand mold or sand core. The bottom surface of the slide block 31 has a downward protruding bump 311 .

[0037] The support frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com