L-phenylglycine decolorization process

A technology of L-phenylglycine and process is applied in the field of L-phenylglycine decolorization technology, which can solve the problems of single decolorization process and unsatisfactory decolorization effect of L-phenylglycine, and achieve the effects of excellent decolorization effect, excellent decolorization effect and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

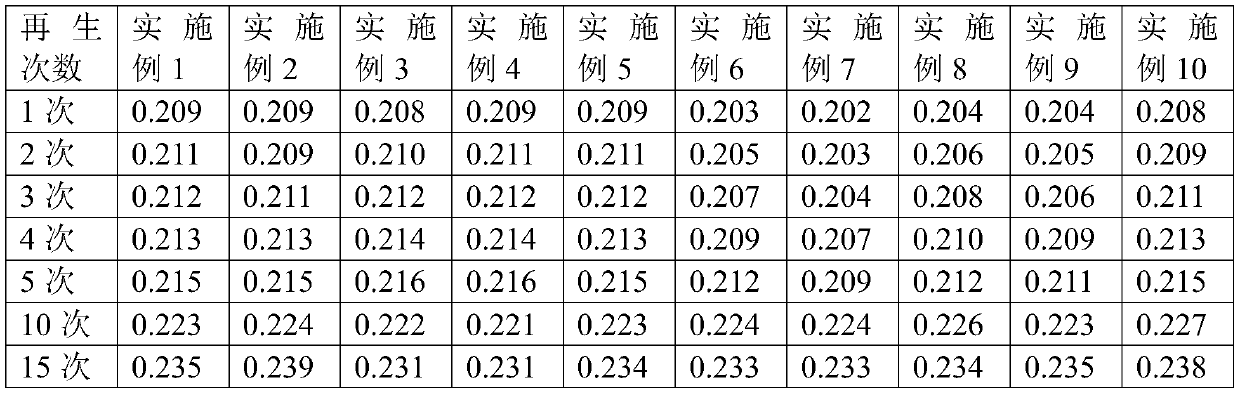

Embodiment 1

[0019] The solution produced by 1000ml L-phenylglycine (pH=9.5, absorbance ((λ=410nm) 1.305) was heated to 50°C, and then the solution produced by L-phenylglycine was passed through a 50mm glass column equipped with a decolorant, and the outside of the glass column was wrapped with Heating belt, heating belt with temperature control system control, control the temperature of the glass column to 60±5°C, control the outflow rate of the solution produced by L-phenylglycine from the glass column to 7ml / min, collect the effluent solution from the glass column, and it is completed Decolorization treatment. The absorbance (λ=410nm) of the outflowing L-phenylglycine solution was detected to be 0.206.

[0020] Described depigmentation agent is: 4g molecular sieve, 7g NaZSM-8 (Si / Al greater than 200) molecular sieve, 25g Naβ (Si / Al greater than 200) molecular sieve, 64g USY molecular sieve. The molecular sieves used are small balls with a diameter of 2-3mm.

[0021] The above-mention...

Embodiment 2

[0025] The solution produced by 1000ml L-phenylglycine (pH=9.5, absorbance ((λ=410nm) 1.305) was heated to 60°C, then the solution produced by L-phenylglycine was passed through a 50mm glass column equipped with a decolorant, and the outside of the glass column was wrapped with Heating belt, heating belt with temperature control system control, control the temperature of the glass column to 60±3°C, control the outflow rate of the solution produced by L-phenylglycine from the glass column to 8ml / min, collect the effluent solution from the glass column, and it is completed Decolorization treatment. The absorbance (λ=410nm) of the outflowing L-phenylglycine solution was detected to be 0.207.

[0026] Described decolorizing agent is: AlPO 4 -34 molecular sieve 5g, NaZSM-5 (Si / Al greater than 200) molecular sieve 15g, Naβ (Si / Al greater than 200) molecular sieve 30g, NaY molecular sieve 50g. The molecular sieves used are small balls with a diameter of 2-3 mm.

[0027] The above-m...

Embodiment 3

[0031] The solution produced by 1000ml L-phenylglycine (pH=9.5, absorbance ((λ=410nm) 1.305) was heated to 70°C, and then the solution produced by L-phenylglycine was passed through a 50mm glass column equipped with a decolorant, and the outside of the glass column was wrapped with Heating belt, heating belt with temperature control system control, control the temperature of the glass column to 70±5°C, control the outflow rate of the solution produced by L-phenylglycine from the glass column to 9ml / min, collect the effluent solution from the glass column, and it is completed Decolorization treatment. The absorbance (λ=410nm) of the outflowing L-phenylglycine solution was detected to be 0.207.

[0032] Described depigmentation agent is: Molecular sieve 2g, AlPO 4 -34 molecular sieve 5g, NaZSM-8 (Si / Al greater than 200) molecular sieve 5g, NaZSM-11 (Si / Al greater than 200) molecular sieve 10g, mordenite (Si / Al greater than 100) 20g, USY molecular sieve 40g, AlPO 4 -5 molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com