Sliding rail type knife rest

A technology of slide rails and tool holders, which is applied in the direction of tool holders, etc., can solve the problems of large rotary diameter of the cutter head, slow rotation of tool changes, and shortened service life of tool holders, achieving less tool change times, reduced tool change times, The effect of increasing the number of stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

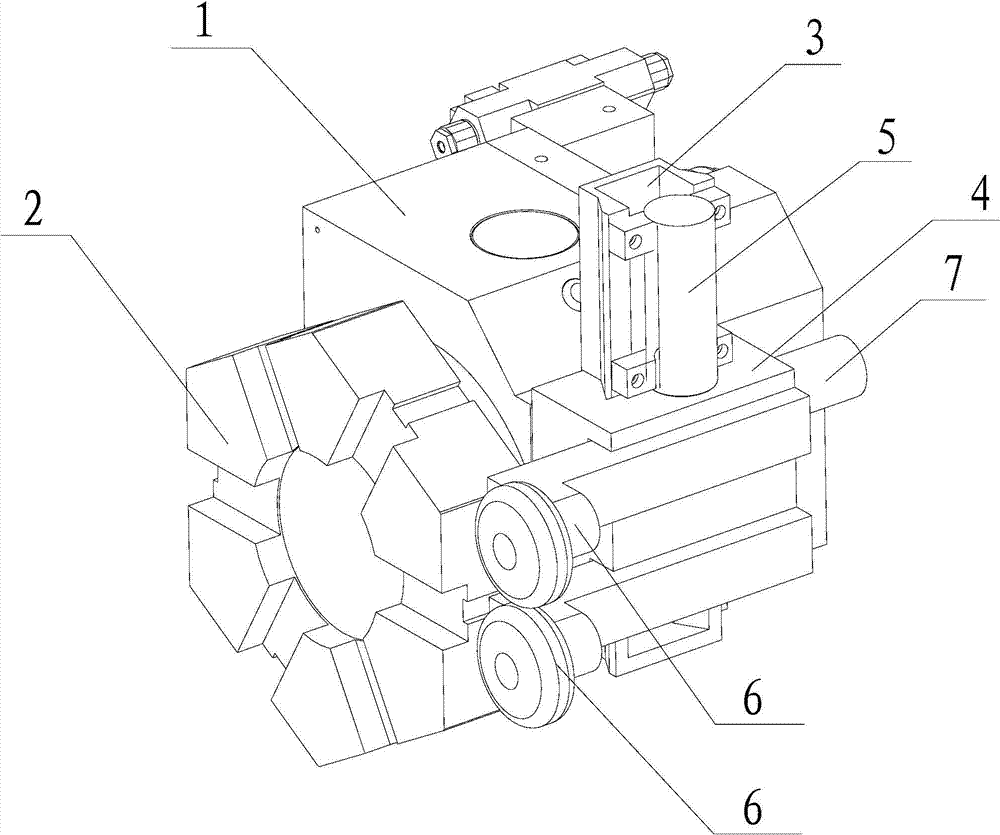

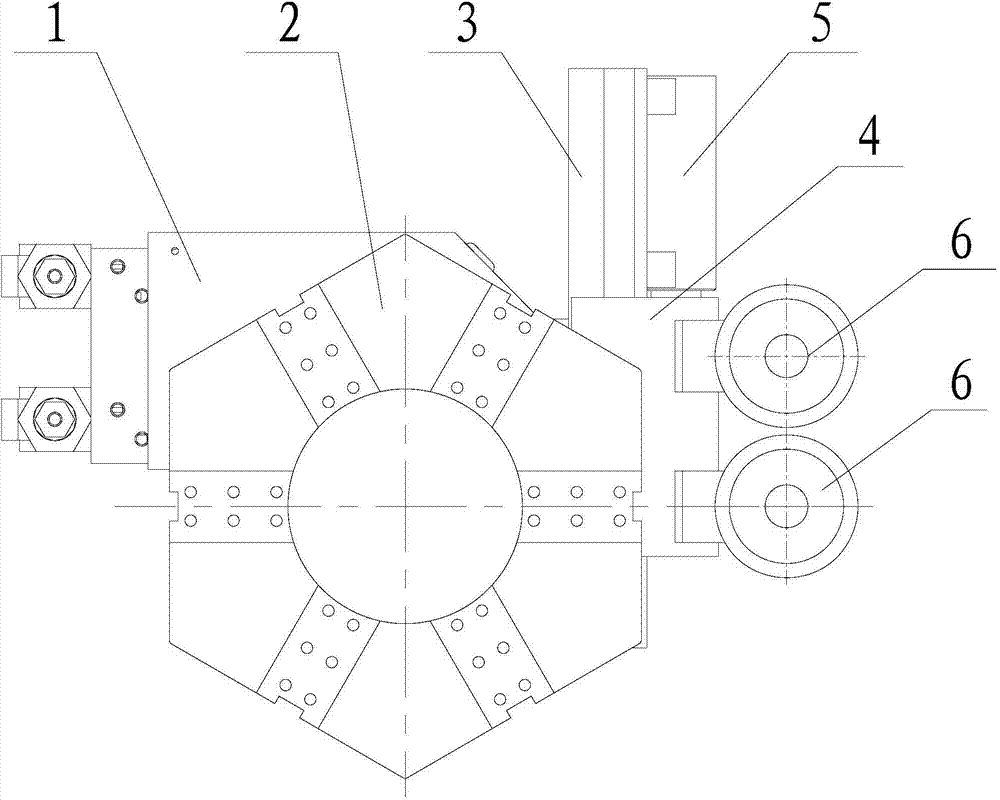

[0021] see figure 1 , figure 2 The slide rail type tool post shown includes a tool holder 1 and a rotary cutter head 2 rotatably arranged at the front end of the tool holder 1. There are 6 stations on the rotary cutter head 2, and knives are respectively installed on the 6 stations. , the stations on the rotary cutter head 2 can be replaced by driving the rotary cutter head 2 to rotate. The knife rest also includes a slide rail 3 fixed on the side of the knife rest 1, the slide rail 3 extends in the vertical direction, the slide rail 3 is provided with a sliding seat 4, and the slide seat 4 is detachably provided with two Knife handle 6, two knife handles 6 are arranged along the up and down direction, and the axis lines of the two knife handles 6 are all parallel to the axis line of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap