Flexible fixture switching mechanism

A switching mechanism and tooling technology, applied in the mechanical field, can solve the problems of low robot reuse rate, lower production efficiency, high equipment cost, etc., achieve excellent quality, improve utilization rate, and save equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

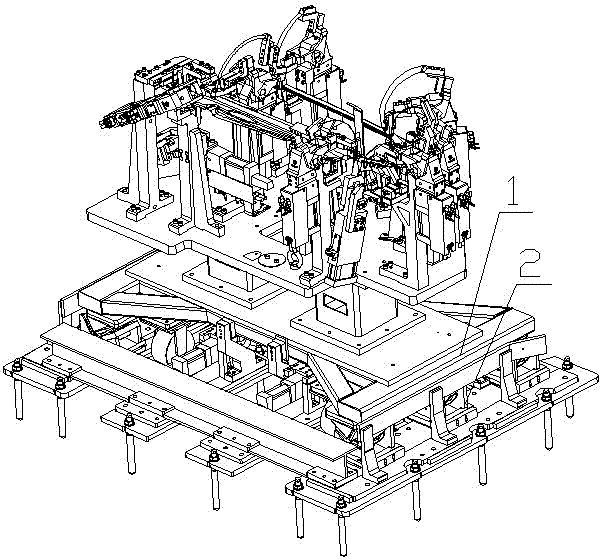

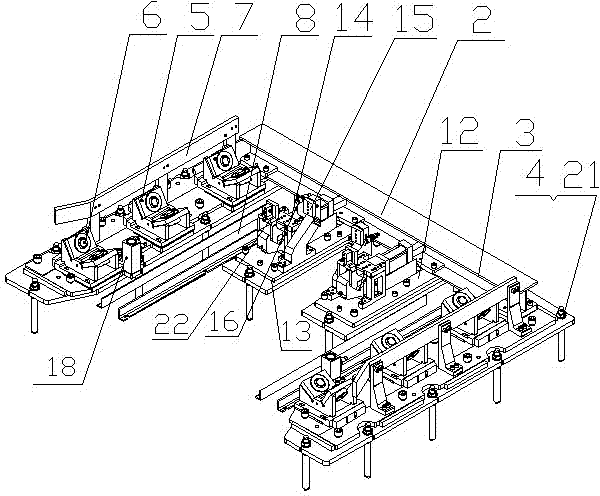

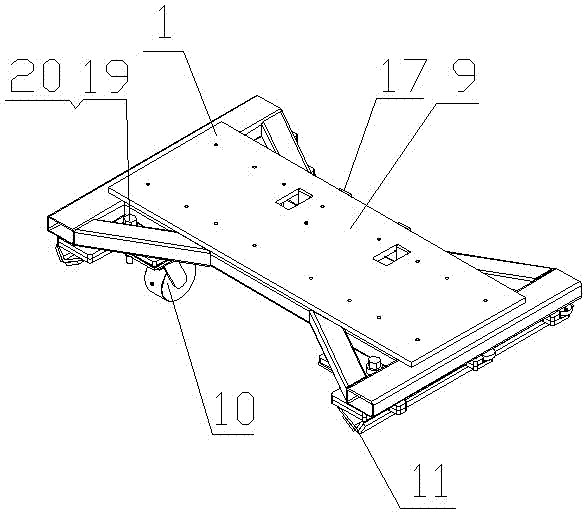

[0016] Such as figure 1 , 2 As shown in , 3, the tooling flexible switching mechanism includes a trolley 1 carrying the tooling and a base 2, the base 2 is fixed on the foundation of the corresponding delivery room by bolts, and the trolley 1 is movably matched on the base 2. The base includes 2 a square frame bottom plate 3 with an open front side, and a number of evenly distributed through holes 4 are arranged on the square frame bottom plate 3. Bolts 21 are respectively built into the through holes 4 for fixing with the foundation of the factory building. The V-shaped guide grooves 5 from front to back are respectively arranged on the two side plates, and at least three universal balls 6 are respectively arranged on the two inner walls of the V-shaped guide groove 5, and the two outer sides of the V-shaped guide groove 5 A side guide plate 7 is arranged on the side plate, and the side guide plate 7 is parallel to the V-shaped guide groove 5, and a guide channel 8 parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com