An engine nacelle sealing fireproof assembly

A technology for engine nacelles and components, which is applied to aircraft parts, transportation and packaging, etc. It can solve the problems of harsh working environment of parts, peeling of fireproof coatings, and exposure of base materials, etc., so as to reduce the frequency of replacement and reinstallation, reduce the The effect of small friction and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

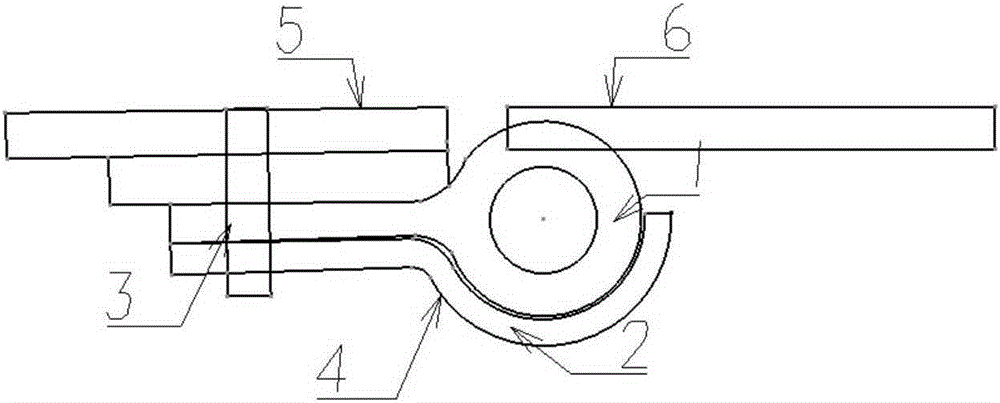

[0015] see figure 1 , which is a structural schematic diagram of the engine nacelle sealing fireproof assembly of the present invention. The engine nacelle sealing fireproof assembly of the present invention is composed of a rubber profile 1 , a spoon-shaped pressing plate 4 and a fastener 3 . Among them, the sealing end of the rubber profile is a cylindrical sealing body with a tadpole-shaped cross section. The free end 2 of the spoon-shaped pressing plate is bent to match the surface of the sealing end of the rubber profile. The fixed end of the spoon-shaped pressing plate is connected to the tail end of the rubber profile and the short The cabin structure 5 is connected and fixed.

[0016] Engine nacelle sealing and fireproof components are mainly used in special parts of aircraft such as engine nacelle structures that have high requirements for fireproo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com