Carbon nanotube bridged phenylphosphonic acid rare earth salt compound decabromodiphenylethane flame retardant polyethylene and preparation method thereof

A technology of decabromodiphenylethane and flame-retardant polyethylene, which is applied in the field of carbon nanotube bridged phenylphosphonic acid rare earth salt compounded decabromodiphenylethane flame-retardant polyethylene and its preparation, can solve the problem of deteriorating polymerization In order to achieve the effect of simple and easy processing method, improved flame retardant performance and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment formula is as follows:

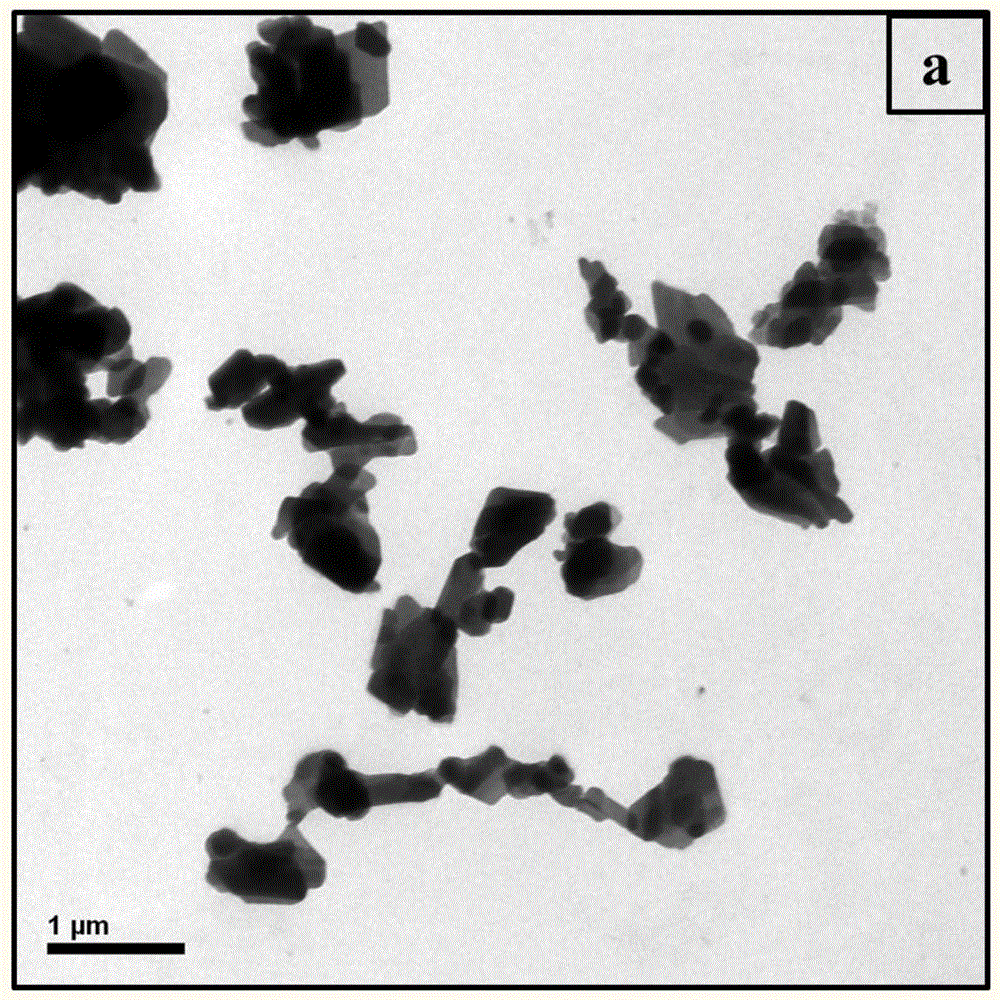

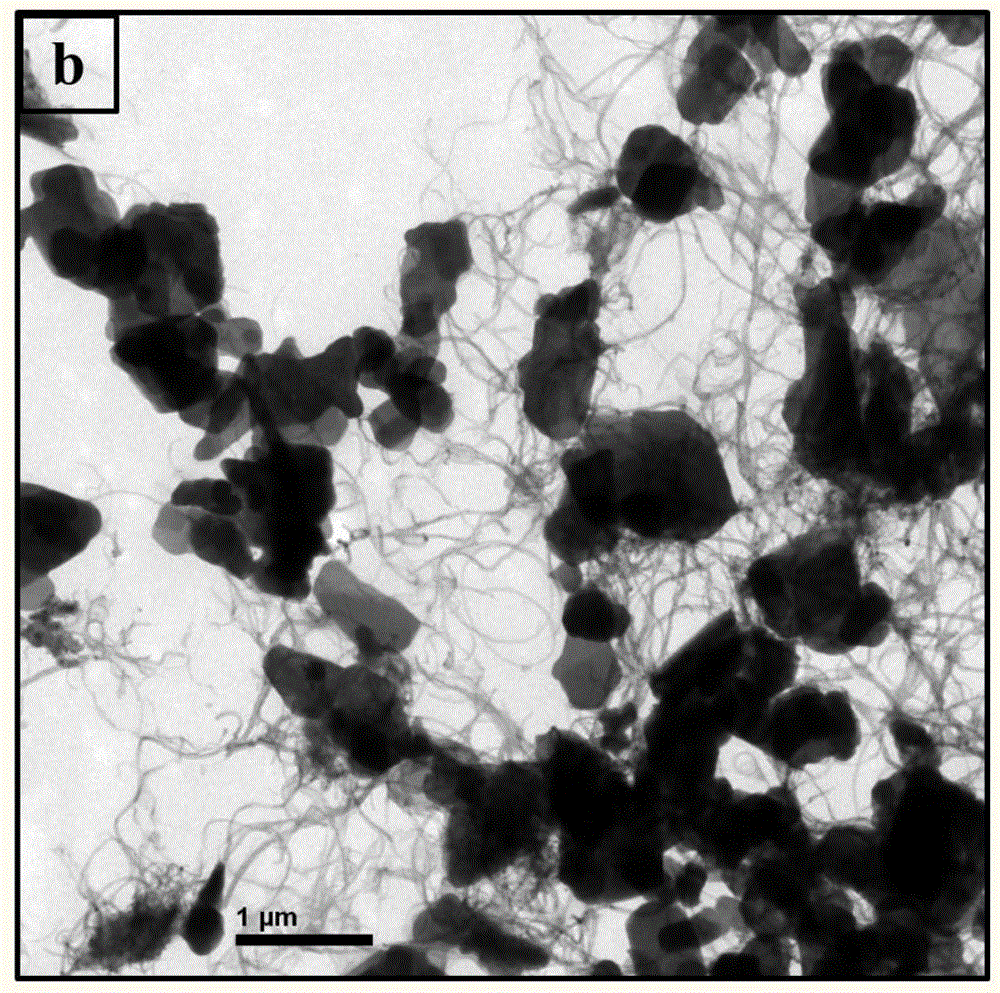

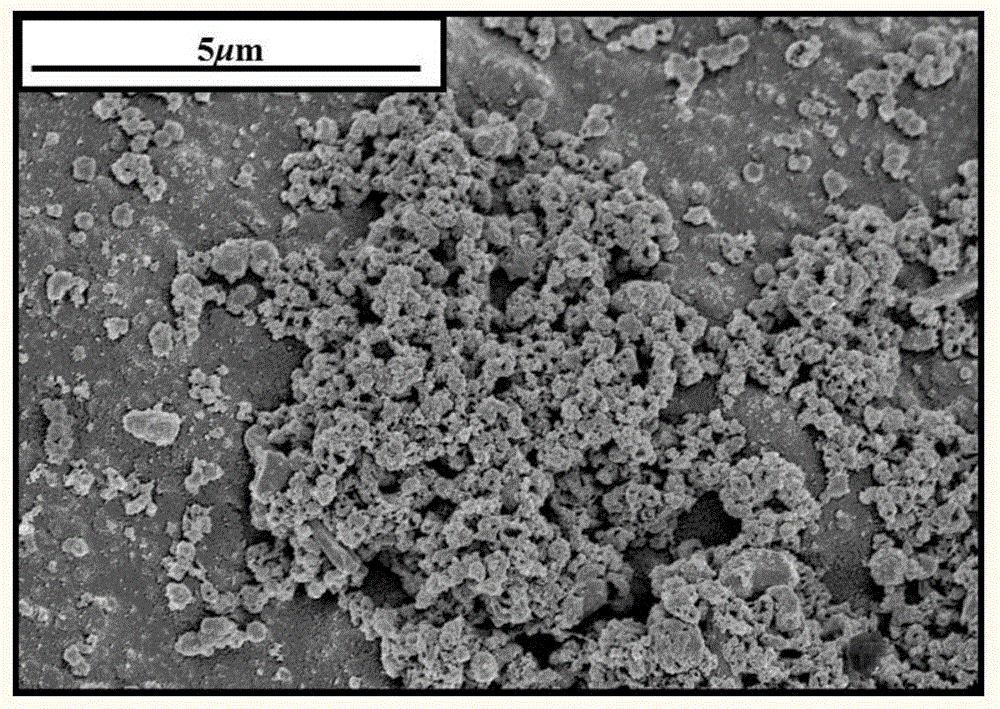

[0034] In this example, the carbon nanotube-bridged phenylphosphonic acid cerium hybrid (Ce-MWNTs) was used for the test, and the hybrid preparation method used the above-mentioned preparation method of the carbon nanotube-bridged phenylphosphonic acid rare earth salt hybrid, specifically: :

[0035] (1) Disperse 2 mmol of phenylphosphonic acid and 0.5 g of aminated multi-walled carbon nanotubes in 50 ml of water, put the suspension into an ultrasonic instrument, and ultrasonicate at 60°C for 0.5 h with a power greater than or equal to 250 W;

[0036] (2) Dissolve 1 mmol of cerium nitrate in 50 ml of water, slowly add this solution dropwise to the solution obtained in step (1), and continue to sonicate at 60°C for 0.5 h.

[0037] (3) The resulting suspension was transferred to a hydrothermal reaction kettle, and then the reaction kettle was placed in an oven at 100°C for 24 hours, and the hydrothermal reaction stopped.

[0038] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com