Preheating-based controllable grinding reinforcing method

A grinding strengthening and preheating technology, applied in the field of grinding processing, can solve the problems of surface roughness reduction, grinding wheel wear, affecting the performance of parts, etc., to improve the uniformity and depth of grinding strengthening, improve durability, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

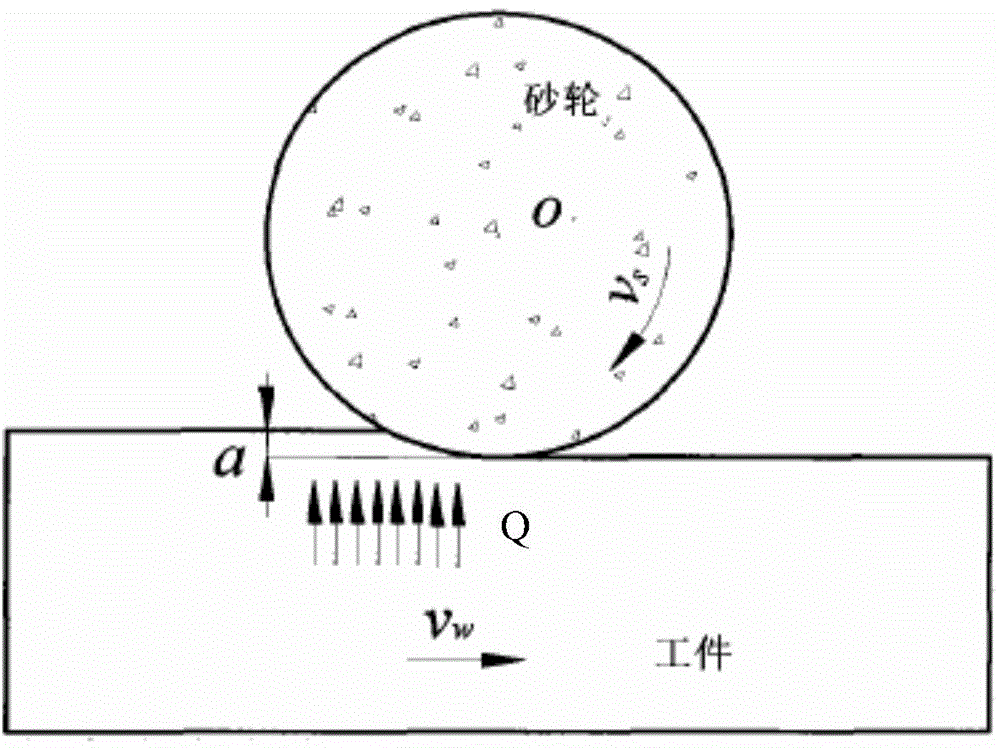

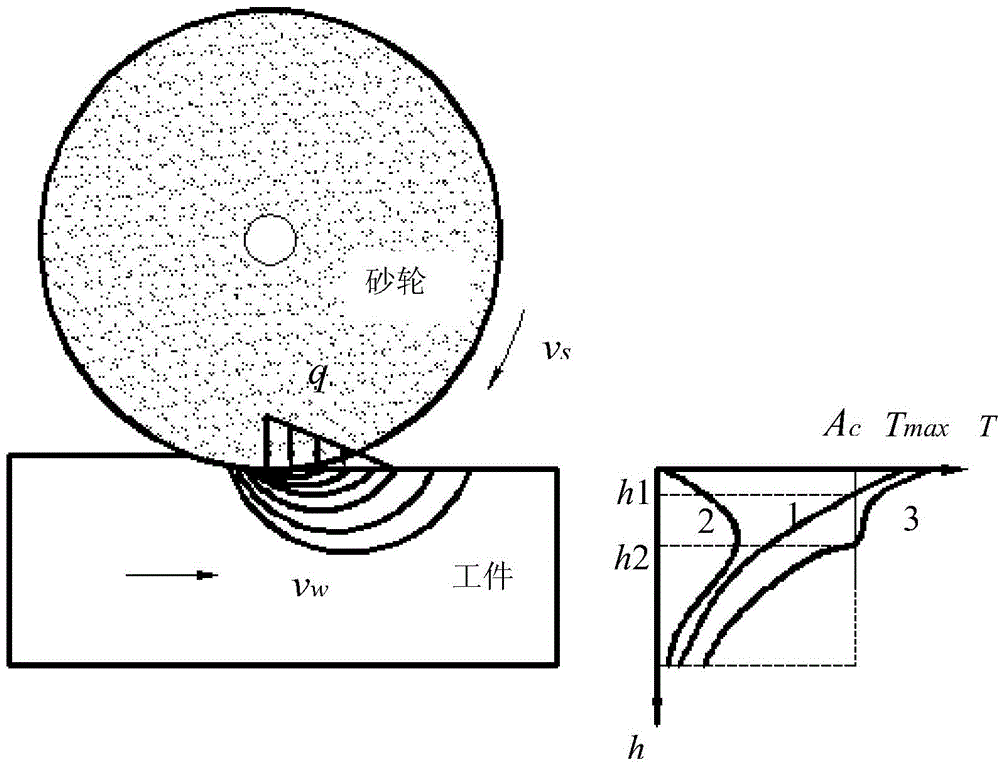

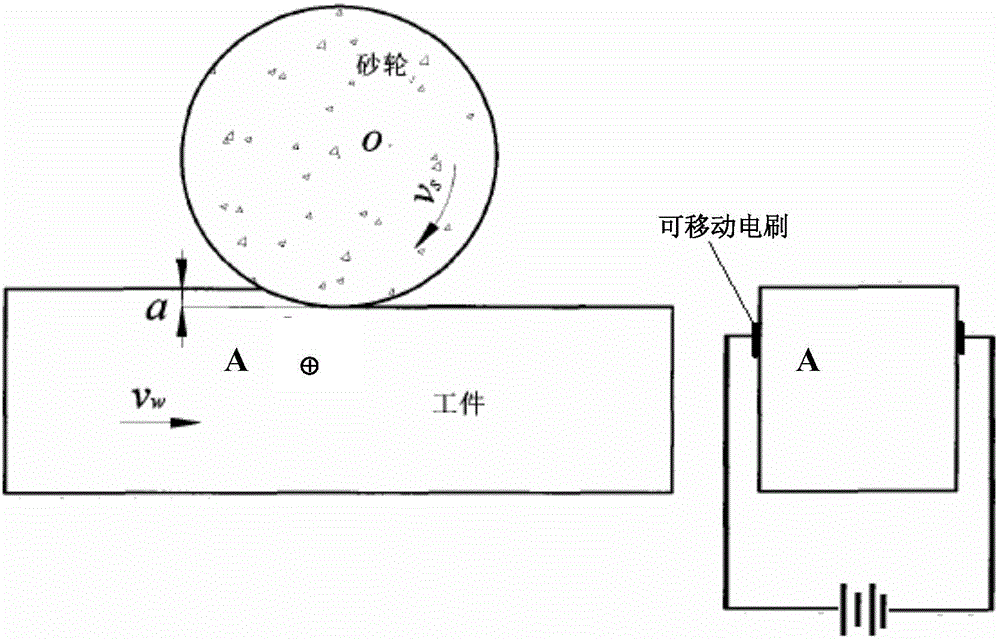

[0017] The main principle of the present invention is: the temperature distribution on the grinding depth during the grinding process (without heating) can be obtained by using simulation as figure 2 In the middle curve 1, the highest temperature is Tmax, and the temperature gradient is relatively large, exceeding the austenite transformation temperature Ac of the material. At this time, the grinding strengthening depth is h1. The workpiece is preheated by using a preheating device (such as low voltage and high current forming a loop at both ends of the workpiece, through the heat generated by the heating resistor), and the temperature distribution in the depth direction of the workpiece is shown in curve 2. Under this condition, the workpiece is ground at the same time. The actual temperature distribution of the grinding process is the superposition of the previous two, as shown in curve 3. At this time, it can be seen that the maximum grinding temperature on the grinding sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com