A method and device for improving the moisture uniformity of tobacco leaves at the outlet of a burley tobacco curing machine

A uniform, burley tobacco technology, applied in the direction of tobacco, preparing tobacco, drying solid materials, etc., can solve problems such as changes in atomization state, and achieve the effects of improving stability and uniformity, improving equipment production efficiency, and prolonging cleaning cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

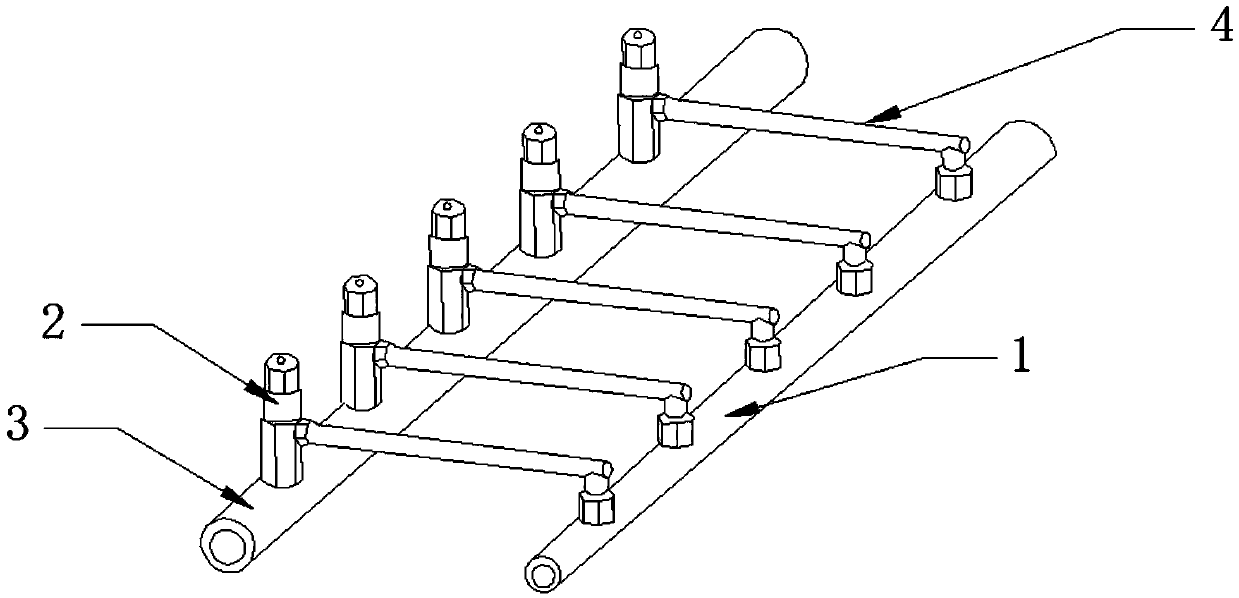

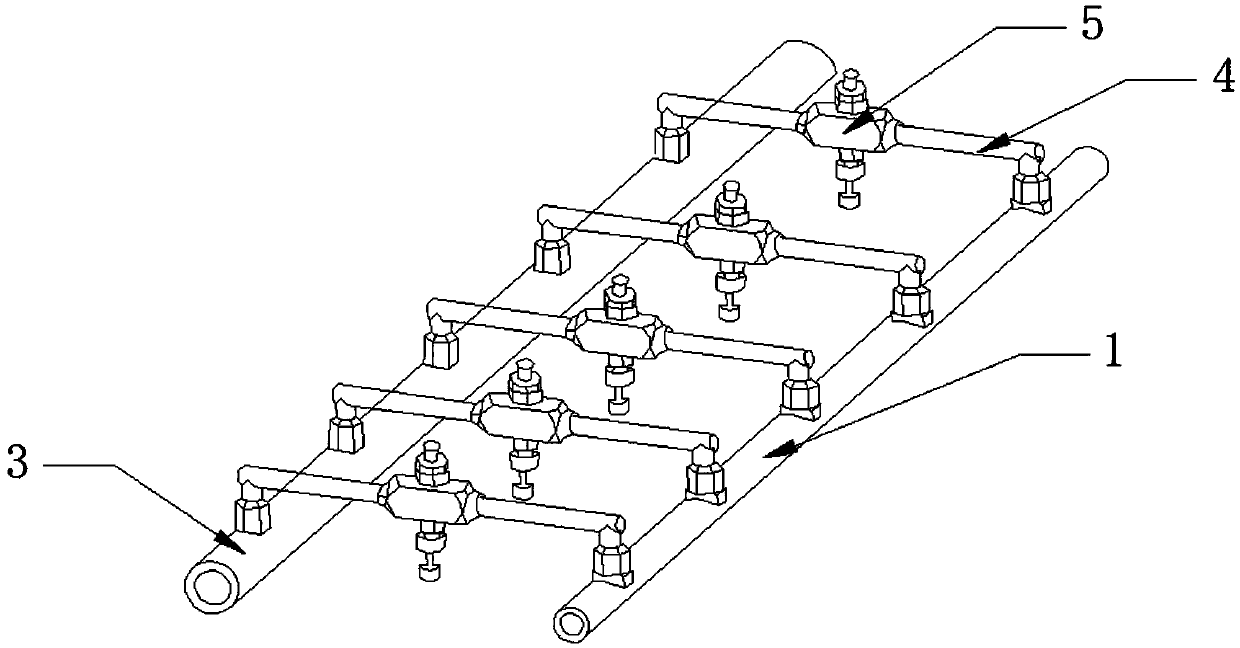

[0026] Such as figure 2 As shown, a device for improving the moisture uniformity of tobacco leaves at the outlet of a Burley tobacco curing machine includes parallel water pipes 1 and steam pipes 3; there are conduits 4 across the water pipes 1 and steam pipes 3 at intervals of 560mm, and the spanning conduits 4 is equipped with and can regulate nozzle 5. The nozzle 5 that can be adjusted is a nozzle that can adjust the amount of sprayed water.

[0027] A method for improving the moisture uniformity of outlet tobacco leaves of a burley tobacco curing machine, comprising the following steps:

[0028] The first step is to estimate the humidification capacity of the moisture resurgence zone of the baking machine;

[0029] The estimation method is that the moisture in the drying area of the tobacco leaf roasting machine is baked and dehydrated to abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com