Steel for motor turbine of roller washing machine and production method thereof

The technology of a drum washing machine and production method, which is applied in the field of metal material processing, can solve the problems of unfavorable cold-rolled sheet stamping and forming, r-value reduction, etc., and achieve the effects of eliminating the yield plateau, preventing Lüders bands, and reducing the outlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

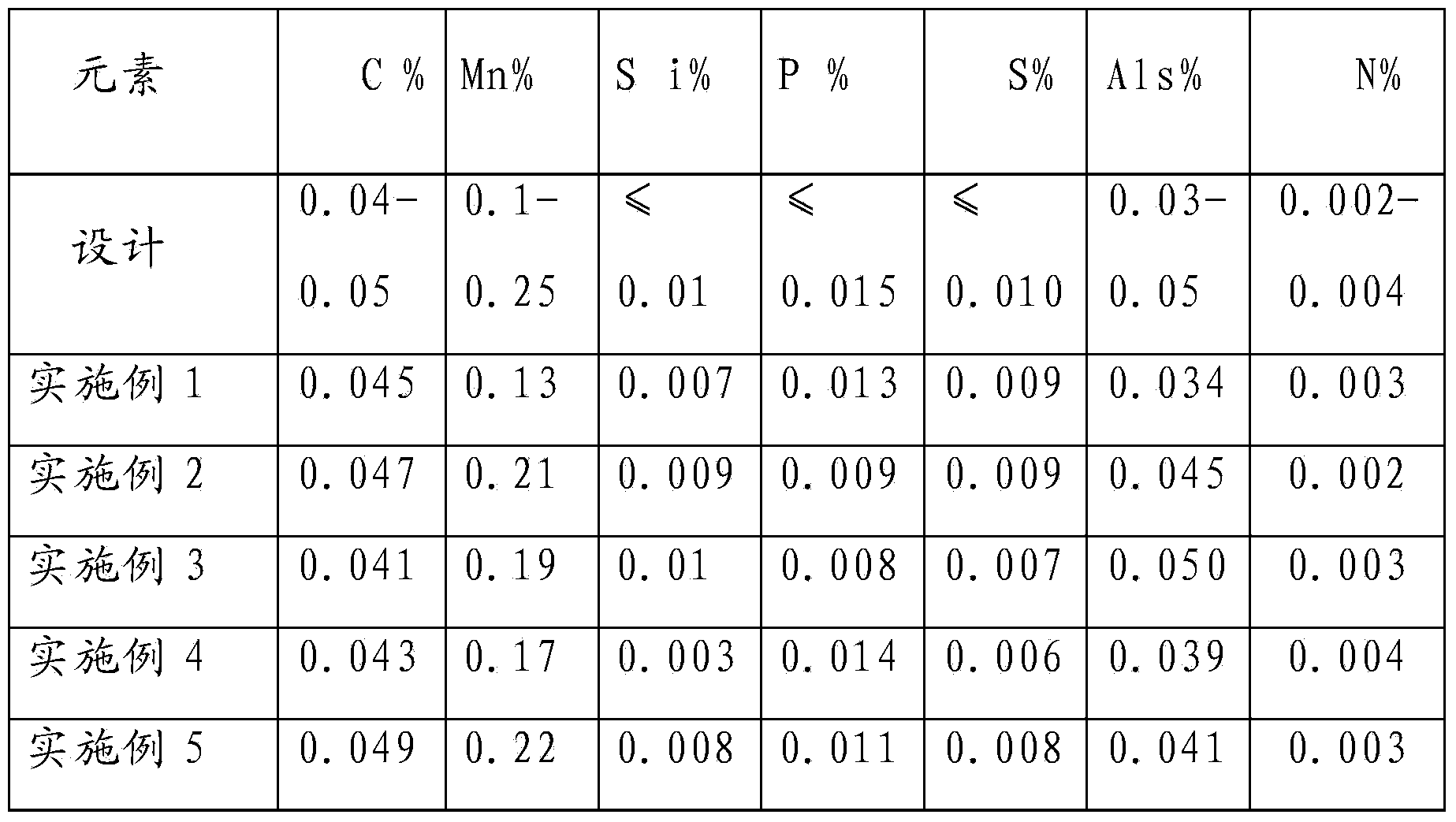

[0015] A kind of steel for drum washing machine motor turbine provided by the embodiment of the present invention, its chemical composition and mass percentage are: C, 0.04-0.05%; Mn, 0.10-0.25%; Si, ≤0.01%; P, ≤0.015%; S , ≤0.01%; Als, 0.03-0.05%, N, 0.0020-0.0040, the balance is Fe and unavoidable impurities.

[0016] The present invention also provides a method for producing steel for a drum washing machine motor turbine, comprising the following steps:

[0017] 1) Desulphurization, converter blowing, RH vacuum refining, and continuous casting of the steel with the chemical composition and mass percentage to obtain a continuous casting slab;

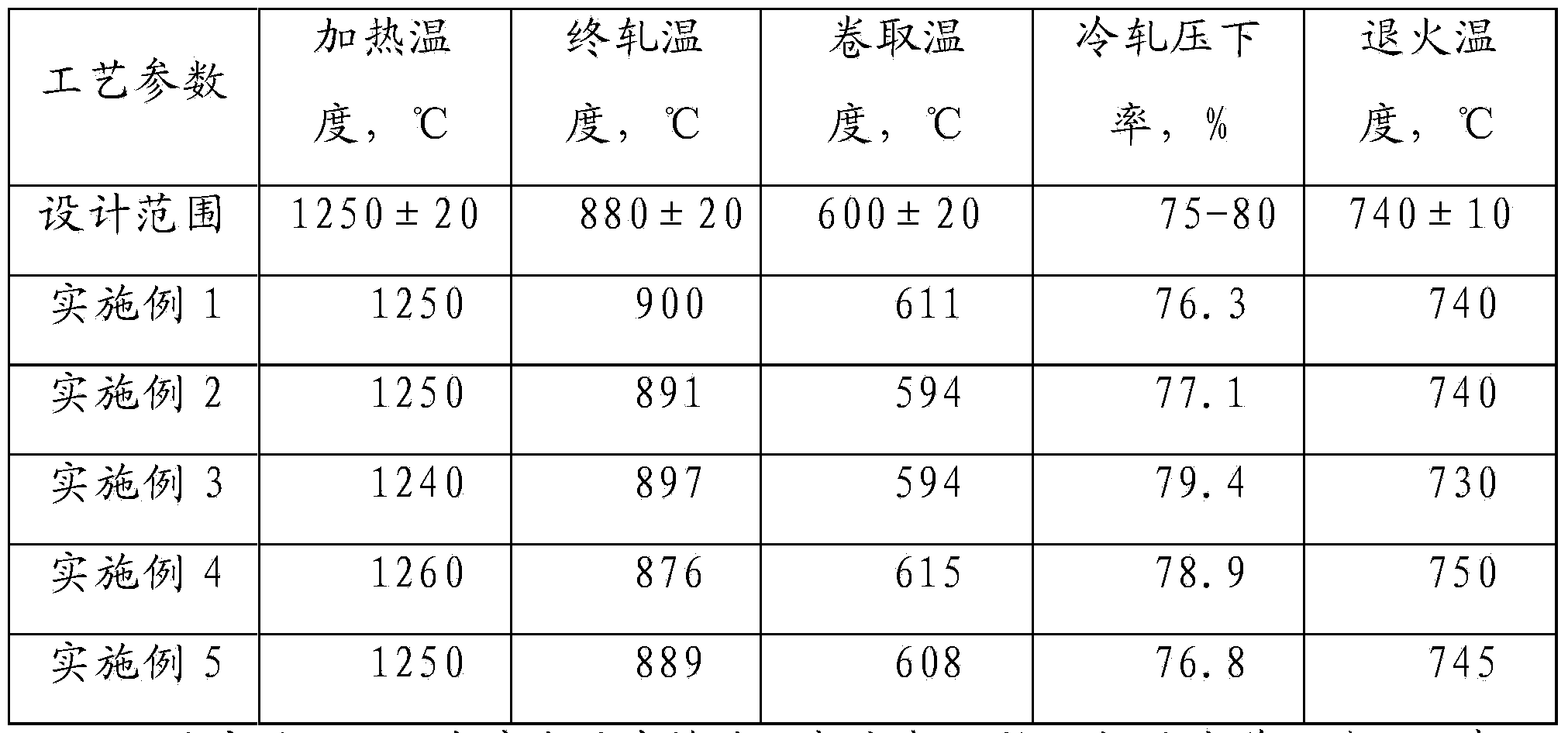

[0018] 2) Heating the obtained continuous casting slab to 1250±20°C for hot rolling, controlling the temperature during final rolling to 880±20°C, and coiling at a temperature of 600±20°C to obtain hot-rolled steel coils;

[0019] 3) The hot-rolled steel coil is uncoiled and pickled, then cold-rolled, and the cold-rolled reduction ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com