Pore blocking method for surface modified layer of fuel cell polar plate

A surface modification layer and fuel cell technology, applied in battery electrodes, metal material coating process, coating, etc., can solve the problems of bipolar plate perforation, high cost of precious metals, battery performance degradation, etc., to improve production efficiency, Low treatment cost and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

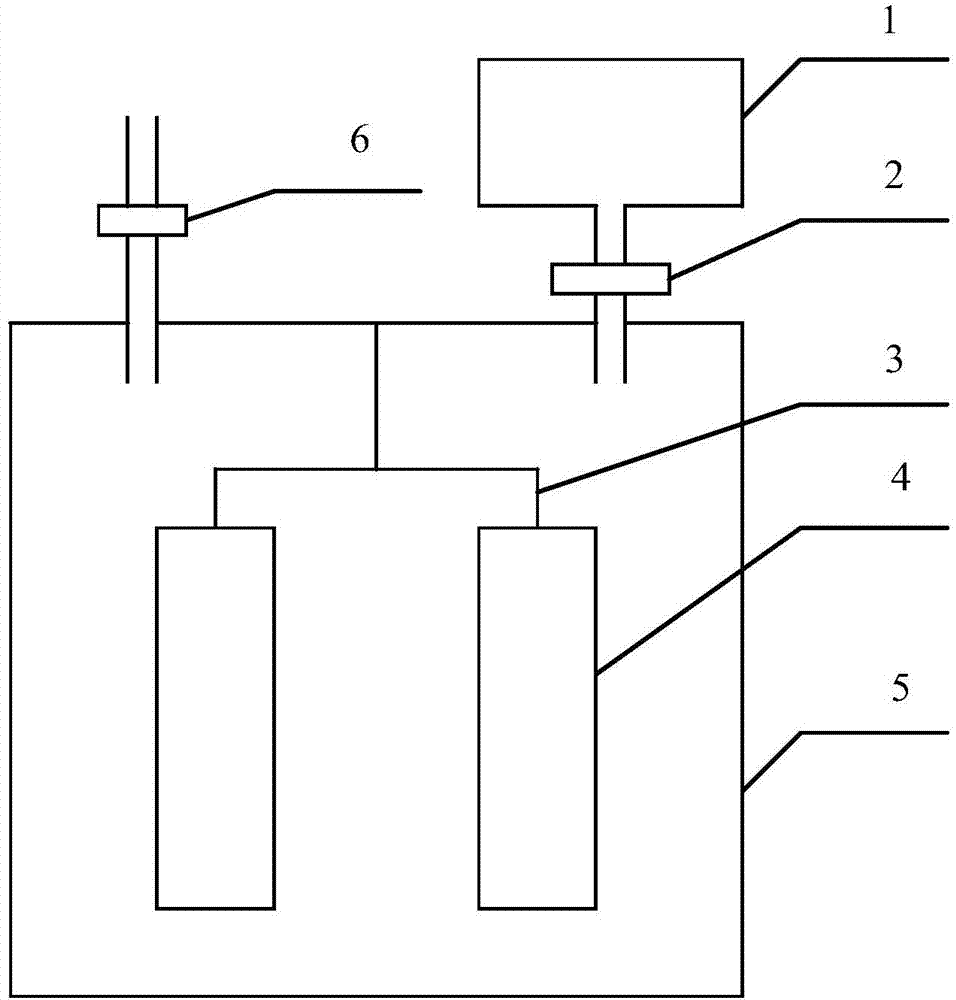

[0018] Such as figure 1 As shown, the treatment method for the plugging of the film layer on the surface of the coated stainless steel bipolar plate used in the proton exchange membrane fuel cell, the processing device includes a vacuum system 1, an exhaust valve 2, a sample turret 3, a coated bipolar plate 4, and a vacuum chamber of the coating equipment 5 and intake valve 6.

[0019] For the bipolar plate to be coated, do not take out the bipolar plate after the coating is completed, directly open the exhaust valve 2 of the vacuum chamber 5 of the coating equipment, and use the vacuum system 1 to reduce the internal pressure of the vacuum chamber 5 of the coating equipment to 5×10 3 Pa5×10 -3 Pa, close the exhaust valve 2 and the vacuum system 1; open the intake valve 6 of the vacuum chamber 5 of the coating equipment, so that air enters the vacuum chamber 5 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com