Stepped reinforced concrete slab capable of preventing abutment vehicle skips and construction method

A technology of reinforced concrete slabs and construction methods, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of bridge abutment jumping, settlement drop, uneven connection between the road surface and the bridge abutment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

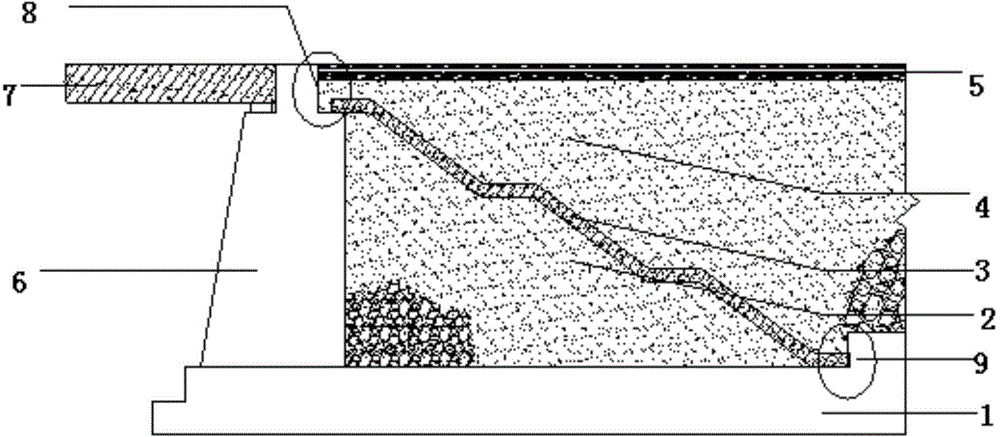

[0035] Such as Figure 6 As shown, a stepped reinforced concrete slab includes a middle partition 10, an upper connection board 11 and a lower connection board 12 are respectively arranged on both sides of the middle partition 10, and the upper connection board 11 and the lower connection board 12 are parallel to each other.

[0036] In this embodiment, the angle between the upper and lower connecting plates and the middle partition is defined as α; the length of the upper and lower connecting plates is the same, defined as L; the distance between the upper and lower connecting plates is defined as H; The thickness between the upper and lower connecting plates is defined as b. The value of α is from 150° to 160°, preferably set at 155°.

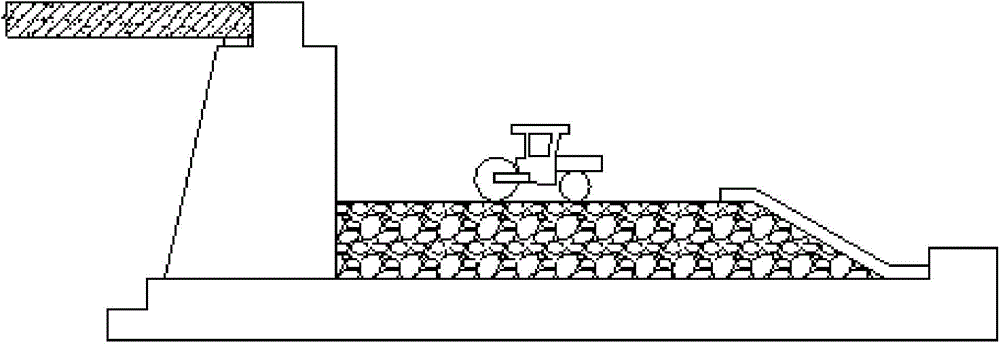

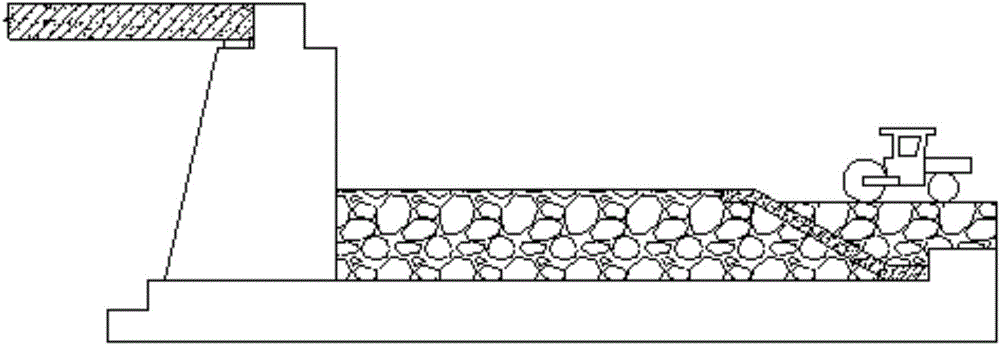

[0037] The method will be further described below in conjunction with the construction process. (Taking the prefabricated stepped reinforced concrete slab as an example, the first and second layers of backfilling and rolling construction at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com