Supporting device and equipment for shield cutter head maintenance work well

A technology of shield cutter head and working well, which is applied to shaft equipment, safety devices, mining equipment, etc., can solve problems such as construction impact, and achieve the effects of controlling lateral deformation, convenient disassembly and assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

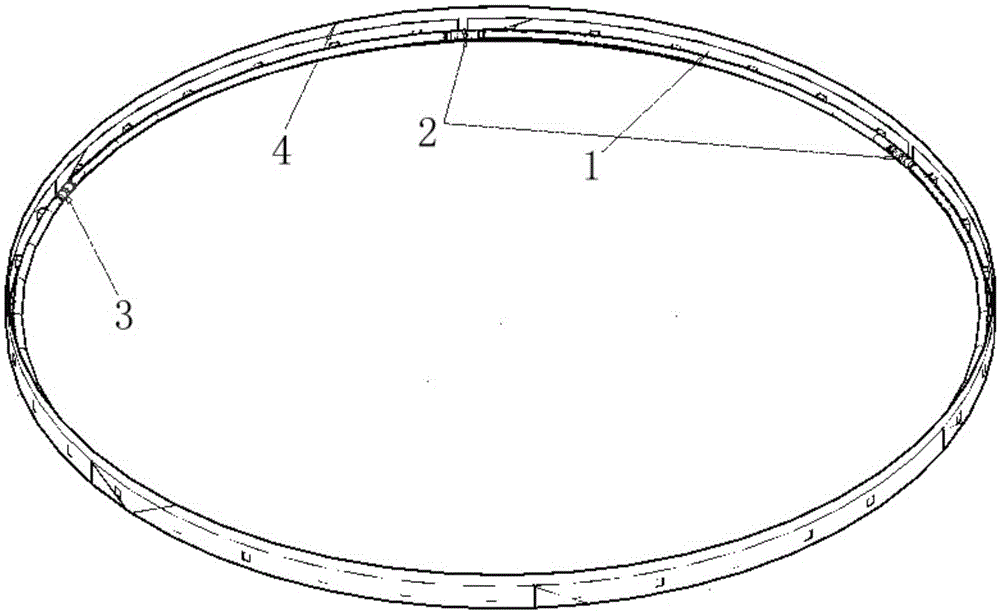

[0027] This embodiment provides a support device for a shield cutter head maintenance work well, such as figure 1 As shown, the device includes: an assembled support structure and an air and water barrier;

[0028] Among them, the assembled support structure is an annular structure formed by connecting multiple support structure units 1, multiple circumferential connecting members 3 and multiple pretensioning members 2;

[0029] The gas and water barrier layer 4 is arranged on the outer surface of the assembled support structure by spiral winding, between the outer surface of the assembled support structure and the inner wall of the working well, and the overlapping of the gas and water barrier layer 4 The width is not less than the height of the assembled support structure.

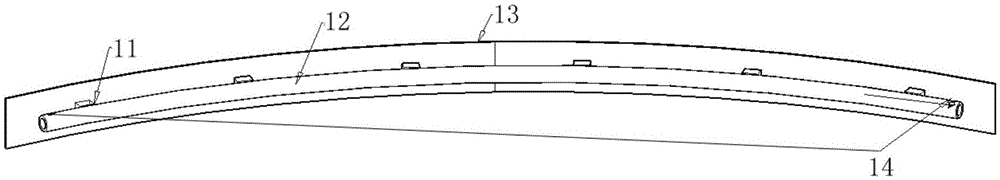

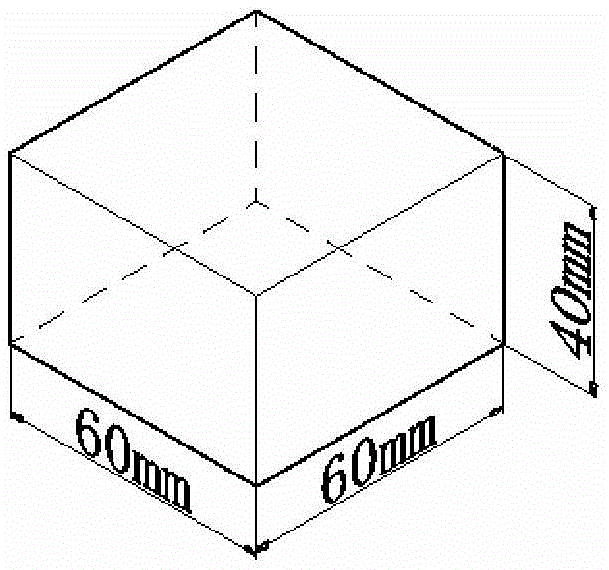

[0030] In the assembled support structure of the above support device, there are six support structure units, such as figure 2 As shown, each support structure unit is welded by arc-shaped steel sheet...

Embodiment 2

[0078] Such as Figure 9 As shown, this embodiment provides a shield cutter head maintenance work well support equipment, including:

[0079] A plurality of assembled support structures 81, a plurality of vertical connecting members 82 and an air and water barrier 83; wherein,

[0080] Each assembled support structure is an annular structure connected by a plurality of support structure units 81, a plurality of hoop connecting members 85 and a plurality of pretensioning members 84;

[0081] A plurality of assembled support structures are arranged in layers, and the assembled support structures of each layer are connected by a number of vertical connecting members 82 to form an overall ring structure;

[0082]The water and gas barrier layer 83 is spirally wound from top to bottom and arranged on the outer surface of the ring structure formed by the plurality of assembled support structures, between the ring structure and the inner wall of the working well, each layer The over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com