Soft foundation water passing wharf structure

A technology of wharf and soft foundation, which is applied in the field of soft foundation water-passing wharf structure, and can solve problems such as insufficient security of the wharf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

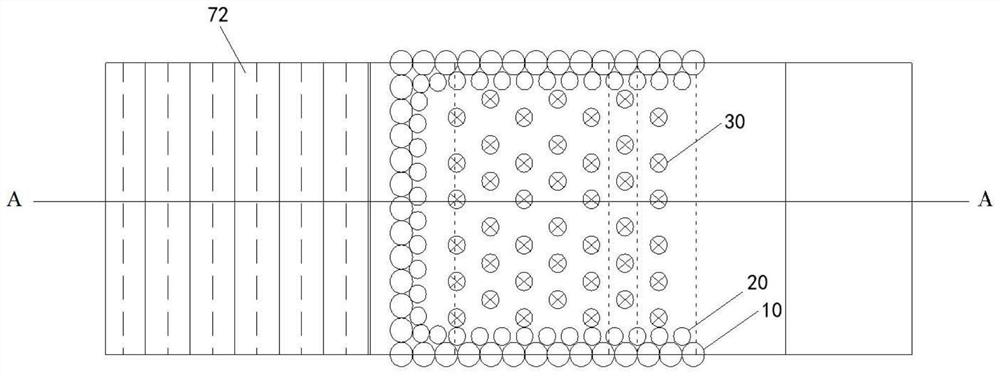

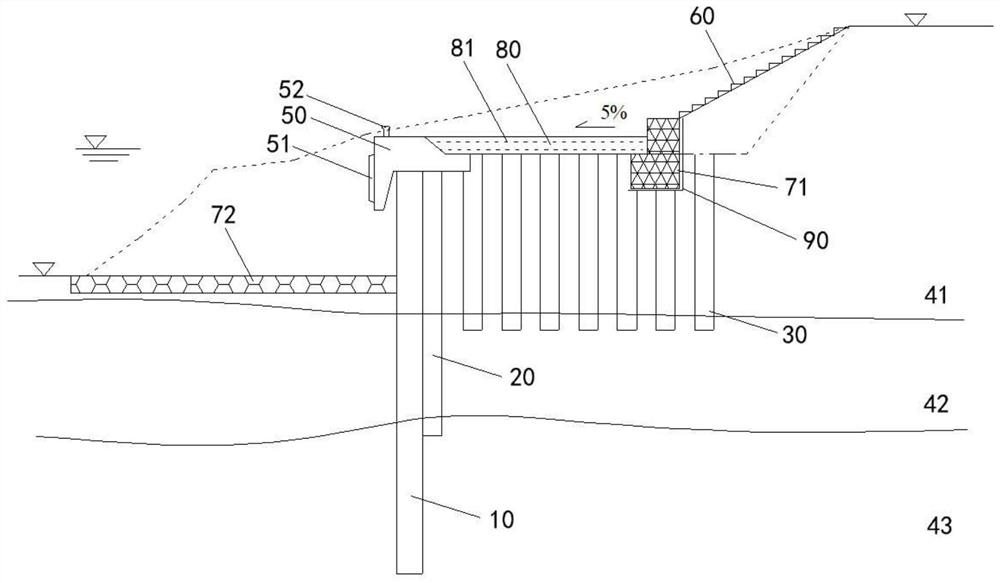

[0030] The invention provides a kind of soft foundation water pier structure, its embodiment is as follows figure 1 and figure 2 As shown, it includes cast-in-situ piles 10, rotary grouting piles 20 and cement-soil mixing piles 30; the cast-in-place piles 10 pass through the silt layer 41, medium-fine sand layer 42 and clay layer 43 of the wharf, and a plurality of cast-in-situ piles 10 surround the outer contour of the wharf Arrangement; the rotary grouting pile 20 is placed in the space surrounded by the cast-in-place pile 10, and a plurality of rotary grouting piles 20 are arranged along the arrangement path of the cast-in-situ pile 10, and the rotary grouting pile 20 passes through the silt layer 41, the medium-fine sand layer 42 and the Clay layer 43; a plurality of cem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com