Cylinder cover with shielding wall structure, manufacturing method and engine

A technology of shielding wall and cylinder head, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of exhaust gas, unable to meet the needs of tumble flow and combustion, unable to meet the needs of gasoline engine use, etc. The effect of flow ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in detail below through the examples. It should be understood that the following examples are exemplary only, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be interpreted as the technical solution of the present invention. limits.

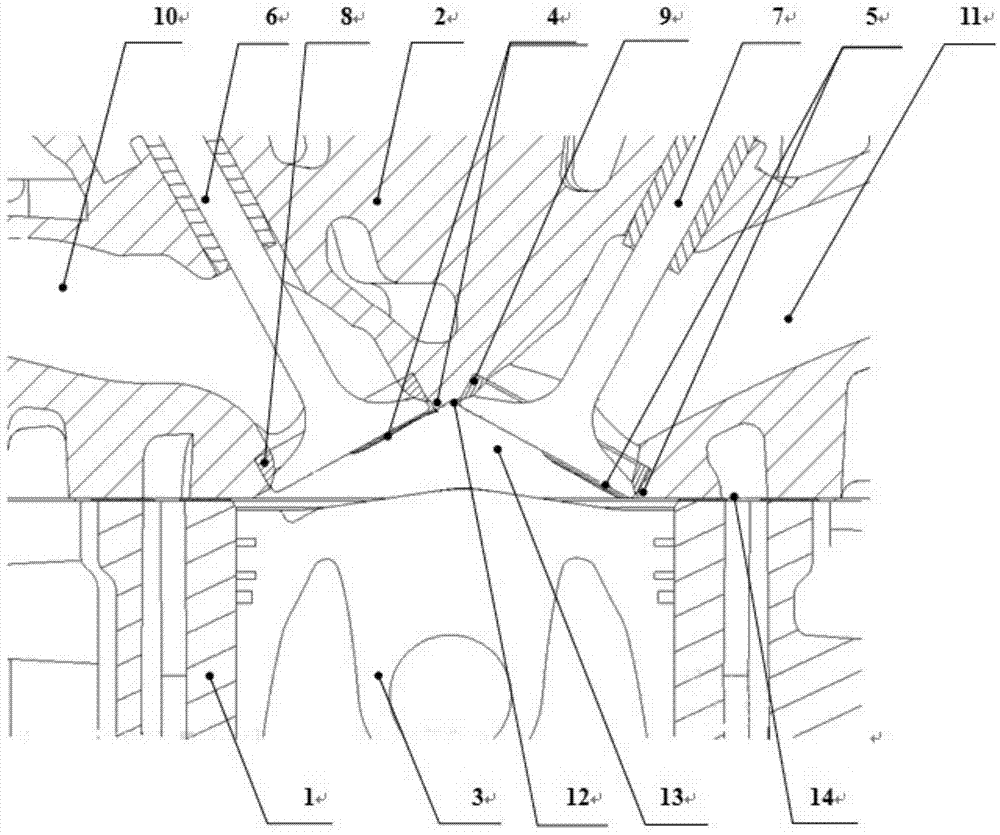

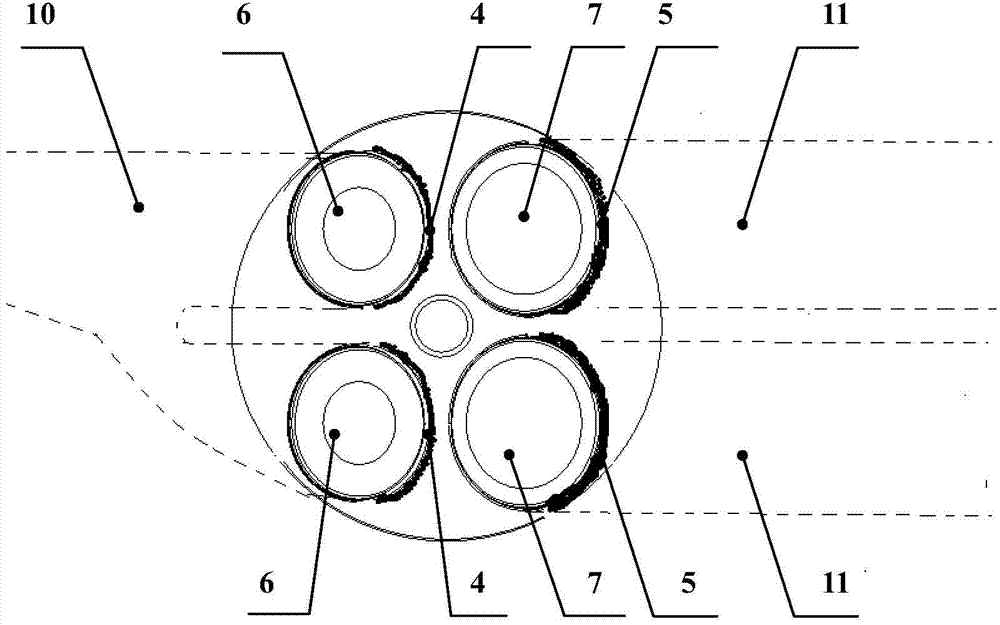

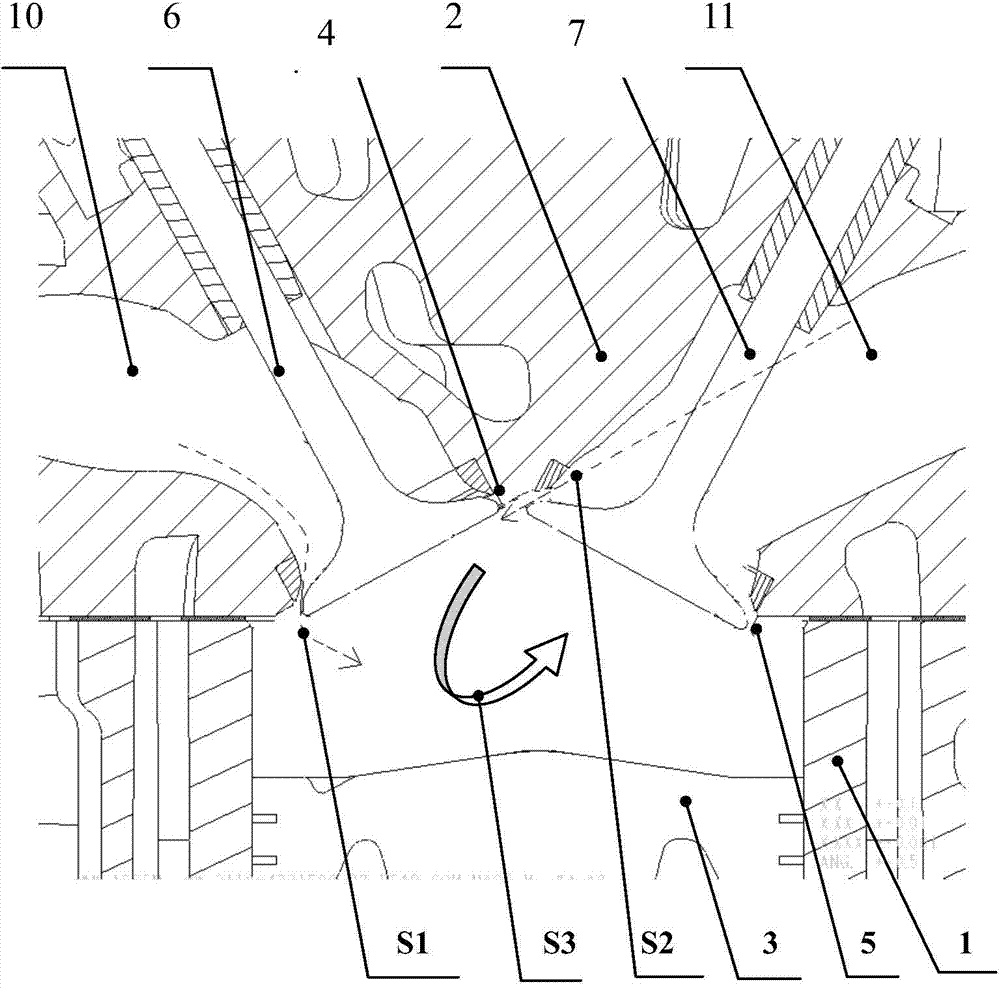

[0030] see figure 1 and figure 2 , the engine cylinder block 1, the piston 3 can reciprocate up and down in the cylinder block 1, the cylinder head 2 is installed on the cylinder block 1 through the seal of the cylinder gasket 14, and the combustion chamber 13 is composed of the cylinder head inner wall 12 of the cylinder head 2 and the piston 3 The upper surface is composed together. The exhaust valve seat 8 and the intake valve seat 9 are respectively press-fitted on the cylinder head 2, and then machined to form good sealing surfaces with the exhaust valve 6 and intake valve 7 respectively. The air channel 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com