Electromagnetic valve resistant to oil pollution

A solenoid valve and anti-oil pollution technology, applied in the field of solenoid valve, can solve problems such as endangering the safe and stable operation of the unit, affecting the normal operation of the speed control system, affecting the working performance of the solenoid valve, etc., achieving simple structure, strong anti-pollution ability, and integration. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

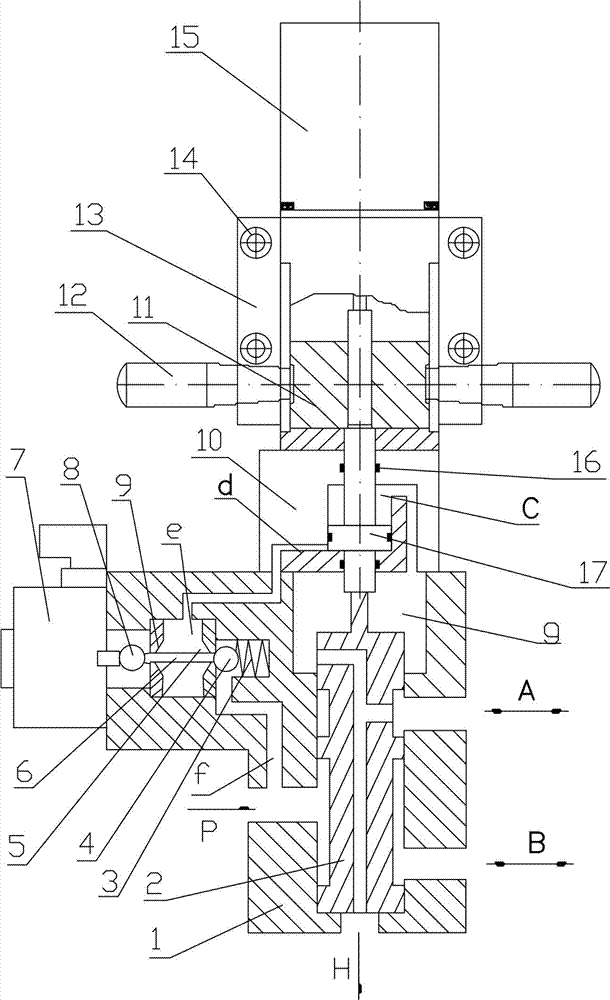

[0014] See attached figure 1 As shown, an anti-oil pollution solenoid valve includes a valve body 1, a valve core 2, a spring 3, a first steel ball 4, a first valve 5, a connecting rod 6, a first electromagnet 7, a second steel ball 8, The second valve 9, housing 10, counterweight 11, bracket 13, second electromagnet 15 and piston 17, the second electromagnet is vertically installed on the bracket, the bracket is installed on the top of the housing, and the valve body is installed on the top of the housing. In the lower part, the bracket has an inner hole, and the counterweight is installed in the inner hole of the bracket, and can move vertically in the hole; the first electromagnet is installed and fixed on the side of the valve body; a piston is installed in the housing, and the upper and lower ends of the piston are provided with Piston rod; the lower end of the iron core of the second electromagnet is connected with the piston rod on the upper part of the piston. The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com