Optical interferometer used for detecting inner surface of hollow cylinder

A hollow cylinder and optical interference technology, which is applied in the field of optical interferometer, can solve the problems of not being able to obtain the three-dimensional surface shape at one time, the influence of interferometer detection accuracy and reliability, and the deviation of detection shape, so as to improve the test efficiency and accuracy , Improve test efficiency, improve accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

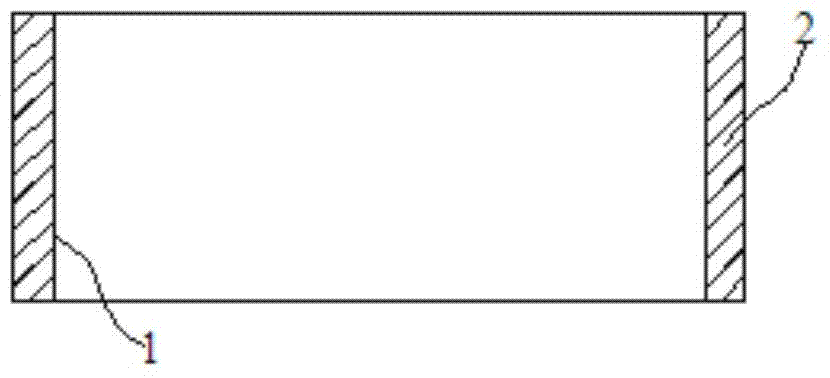

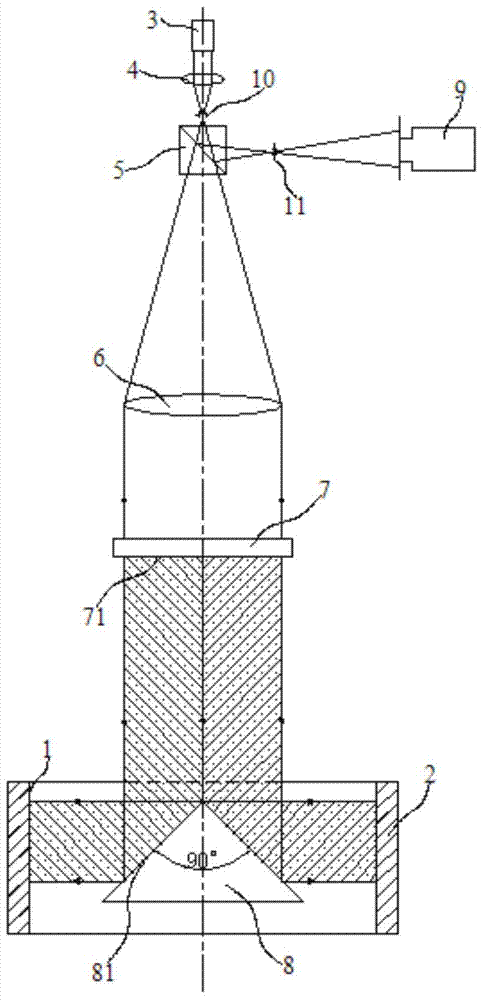

[0025] Embodiment 1: An optical interferometer for detecting the inner surface of a hollow cylinder. The inner surface 1 is located along the circumference of the hollow cylinder 2 and located inside, and includes a laser 3, a condenser lens 4, a beam splitter 5, and an objective lens. A collimating convex lens 6, a standard flat crystal 7 and a conical mirror 8. The condensing convex lens 4 is located between the laser 3 and the collimating convex lens 6, and the focal point of the condensing convex lens 4 coincides with the focal point of the collimating convex lens 6; The beam lens 5 is located between the condensing convex lens 4 and the collimating convex lens 6, and is used to divide the light from the collimating convex lens 6 into a first beam and a second beam; the standard flat crystal 7 is located between the collimating convex lens 6 and the beam splitting lens 6 On the opposite side of the mirror 5, the surface of the standard flat crystal 7 opposite to the collimat...

Embodiment 2

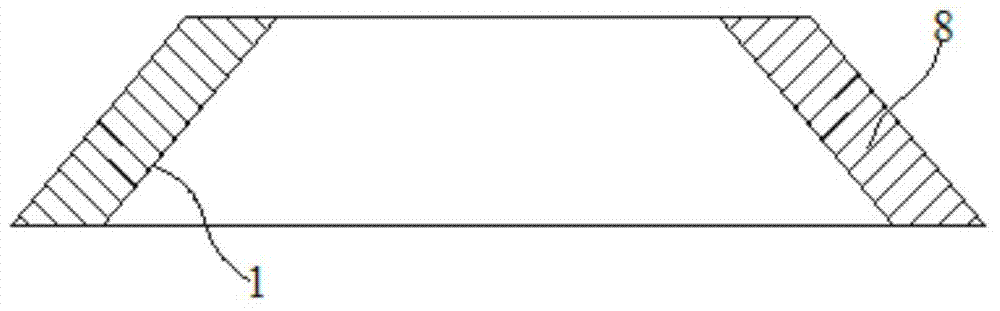

[0032] Embodiment 2: An optical interferometer for detecting the inner surface of a hollow cylinder. The inner surface 1 is located along the circumference of the hollow cylinder 2 and located inside, and includes a laser 3, a condenser lens 4, a beam splitter 5, and an objective lens. A collimating convex lens 6, a standard flat crystal 7 and a conical mirror 8. The condensing convex lens 4 is located between the laser 3 and the collimating convex lens 6, and the focal point of the condensing convex lens 4 coincides with the focal point of the collimating convex lens 6; The beam lens 5 is located between the condensing convex lens 4 and the collimating convex lens 6, and is used to divide the light from the collimating convex lens 6 into a first beam and a second beam; the standard flat crystal 7 is located between the collimating convex lens 6 and the beam splitting lens 6 On the opposite side of the mirror 5, the surface of the standard flat crystal 7 opposite to the collimat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com