Method and device for detecting roughness of inner surface of micro-pore

A detection method and detection device technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that the sensor cannot penetrate into the microhole, etc., and achieve the effects of shortening the detection time, improving the measurement accuracy, and improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

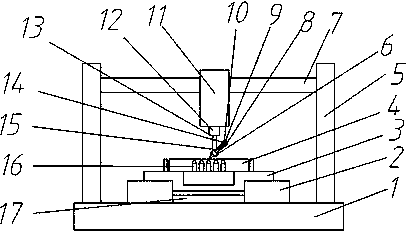

[0027] The present invention will be further described below in conjunction with accompanying drawing.

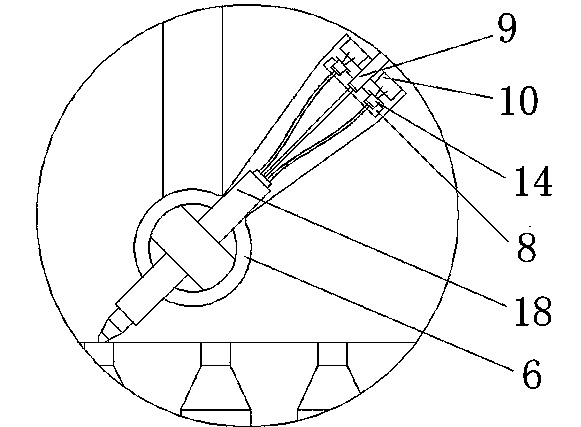

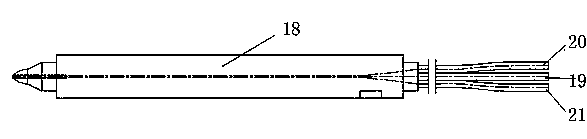

[0028] The device provided by the present invention to realize the detection method of the micropore inner surface roughness is as figure 1 As shown, it includes a three-dimensional workbench, a laser emitter 9, a photodetector 14 and a RIM_FOS sensor 15, and the base 1 of the three-dimensional workbench is provided with a Y-axis precision moving stage 2, an X-axis precision moving stage 3, and a sample stage 4 in sequence. A Y-axis precision guide hole 17 is opened between the axis precision moving table 3 and the base 1 . The top of the base 1 is equipped with a cross bar 7 through the bracket 5, and the middle of the cross bar 7 passes through the Z-axis precision guide box 11, the Z-axis precision moving table 12, the Z-axis rotating vertical bar 13 and the sensor fixture 6 to clamp the RIM_FOS sensor 15, the laser The emitter 9 and the photodetector 14 are connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cladding diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Cladding diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com