Digital pressure meter used in extreme site environment

A pressure gauge and digital technology, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of low ambient temperature, failure to check in time, easy failure of digital display electric pressure gauge, etc., achieve high degree of informatization, and facilitate remote control Monitor the effect of management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

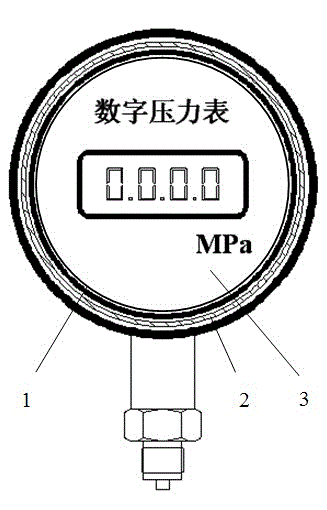

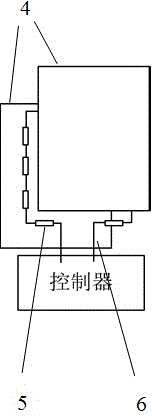

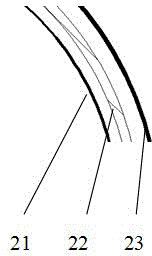

[0028] figure 1 , figure 2 A schematic diagram of the structure of the present invention is given. A digital pressure gauge used in an extreme site environment is composed of a pressure gauge case 1, a thermal insulation cover 2, a heating control device 3, and a radio transmission part. Wherein the thermal insulation cover 2 comprises: the heat-absorbing layer 21 that is made of heat-absorbing material coating, the double-layer vacuum glass 22, the heat-insulation layer 23 that heat-insulating material is made of main parts such as composition, see image 3 . Vacuumize and seal the double-layer glass to form a double-layer vacuum glass 2 wrapped on the surface of the voltmeter case; the heat-absorbing layer 1 is evenly attached to the inner side of the double-layer vacuum glass 2 (the front of the pressure gauge is not coated with heat-absorbing material to ensure transparency Therefore, normal readings), the heat absorbing layer is made of semi-liquid dark material, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| solidification point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com