Method for determining bituminous coal caking index

A technology of cohesion index and measurement method, which is applied in the field of determination of bituminous coal cohesion index, can solve problems such as difficulty in ensuring data accuracy and unspecified pulverization time of coal samples, so as to improve accuracy and repeatability and avoid artificial The effect of the influence of factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

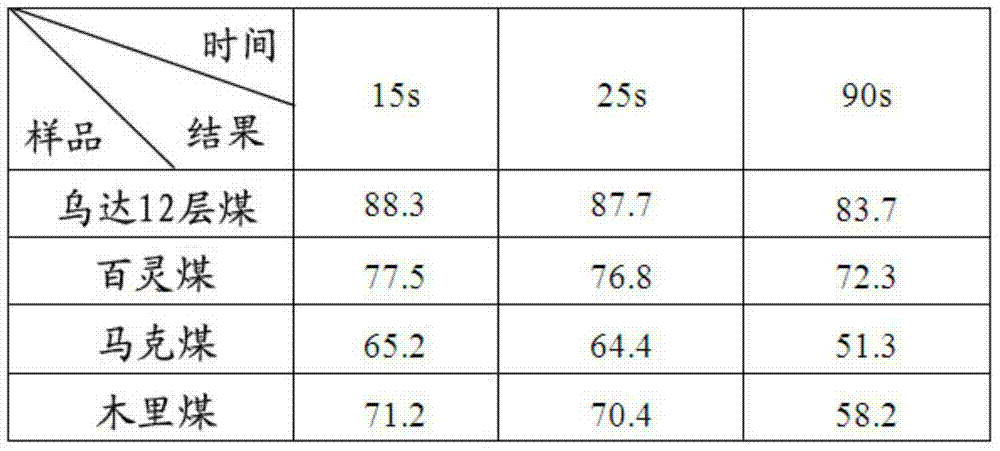

Examples

Embodiment

[0028] 1. Sample preparation

[0029] Test coal sample preparation steps and test steps after mixing said test coal sample with special anthracite, wherein:

[0030] Described test coal sample preparation step comprises following process:

[0031] The test coal samples were prepared as air-dried bituminous coal with particle size less than 0.2mm according to GB474-2008, in which coal particles of 0.1-0.2mm accounted for 20-35wt% of all coal samples; 3mm round hole sieve for sieving, and further crush the oversize of the round hole sieve with a hole diameter of 3mm until all pass through; use a dichotomer to shrink the undersize to get no less than 100g of bituminous coal; the iron filings in the bituminous coal that have been shrunk and separated are sucked away by a magnet; the bituminous coal after removing the iron filings is pulverized by a sample preparation pulverizer, and the pulverized bituminous coal is screened by a square hole sieve with an aperture of 0.2 mm. And...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com