A lithium battery automatic feeding system

An automatic feeding and lithium battery technology, applied in the direction of electrode manufacturing, dissolving, mixing machines, etc., can solve the problems of unguaranteed production environment, high labor intensity, and low production efficiency, so as to reduce manual labor intensity, ensure accuracy and guarantee quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

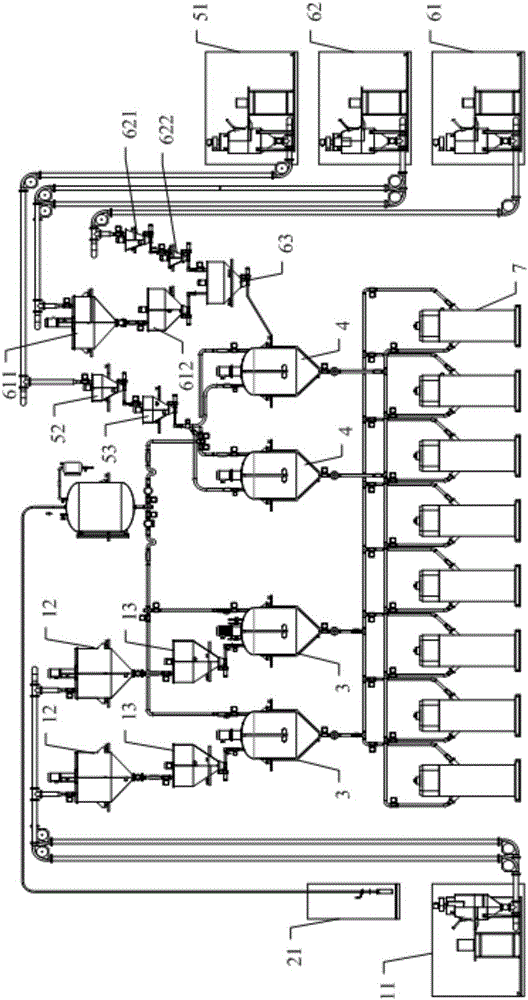

[0029] An automatic lithium battery feeding system in this embodiment includes an electrode material unit, a mother liquor unit, and a stirring motor, and the electrode material unit and the mother liquor unit are respectively connected to the stirring motor;

[0030] The electrode material unit includes an electrode main material feeding device, a solvent feeding device 21 and an electrode material dispersion kettle 3, and the electrode main material feeding device and the solvent feeding device 21 are respectively connected to the electrode material dispersion kettle 3;

[0031] The electrode main material feeding device is used to transport the electrode main material to the electrode material dispersion kettle 3 after being vacuumed, and the solvent feeding device 21 is used to transport the solvent to the electrode material dispersion kettle 3 after vacuuming, and the electrode material is dispersed Kettle 3 is used to disperse the mixed material of electrode main material...

Embodiment 2

[0040] In this embodiment, an automatic lithium battery feeding system includes an electrode material unit, a mother liquor unit, and a stirring motor, and the electrode material unit and the mother liquor unit are respectively connected to the stirring motor;

[0041]The electrode material unit includes an electrode main material feeding device, a solvent feeding device 21 and an electrode material dispersion kettle 3, and the electrode main material feeding device and the solvent feeding device 21 are respectively connected to the electrode material dispersion kettle 3;

[0042] The electrode main material feeding device is used to transport the electrode main material to the electrode material dispersion kettle 3 after being vacuumed, and the solvent feeding device 21 is used to transport the solvent to the electrode material dispersion kettle 3 after vacuuming, and the electrode material is dispersed Kettle 3 is used to disperse the mixed material of electrode main material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com