Weight loss type feeding machine for liquid feeding

A technology of feeding machine and feeding mechanism, which is applied in the direction of mixer, mixer accessories, various fluid ratio control, etc., can solve problems such as structure to be improved, unfavorable mixing, and insufficient smooth material transportation, so as to improve feeding effect, Anti-volatility and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

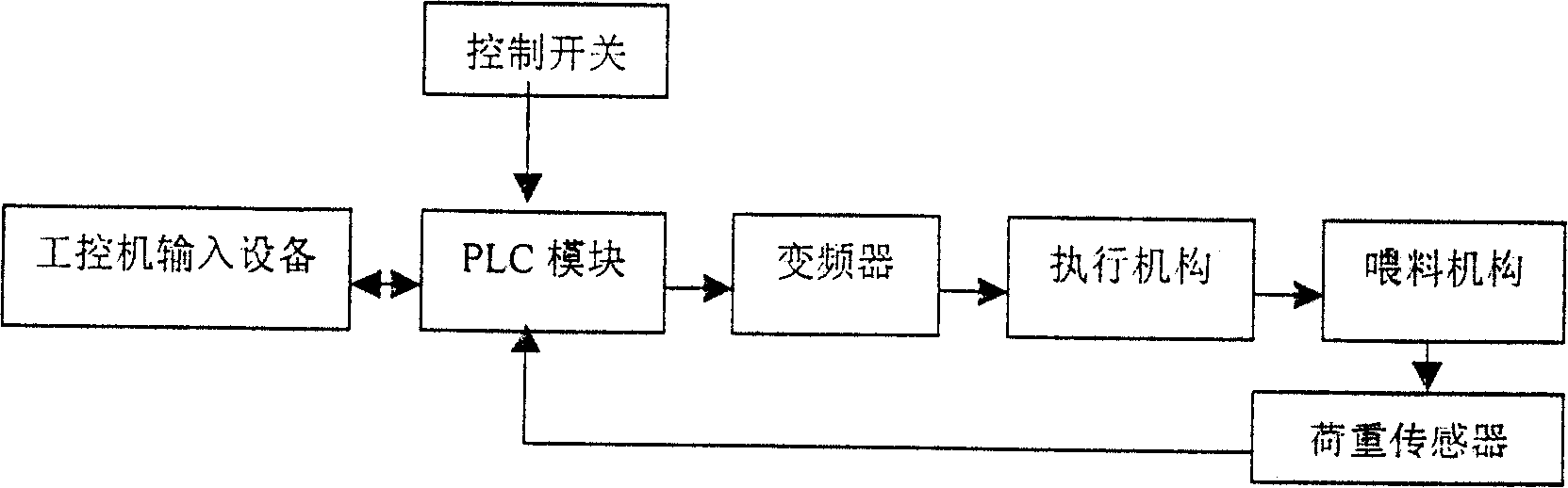

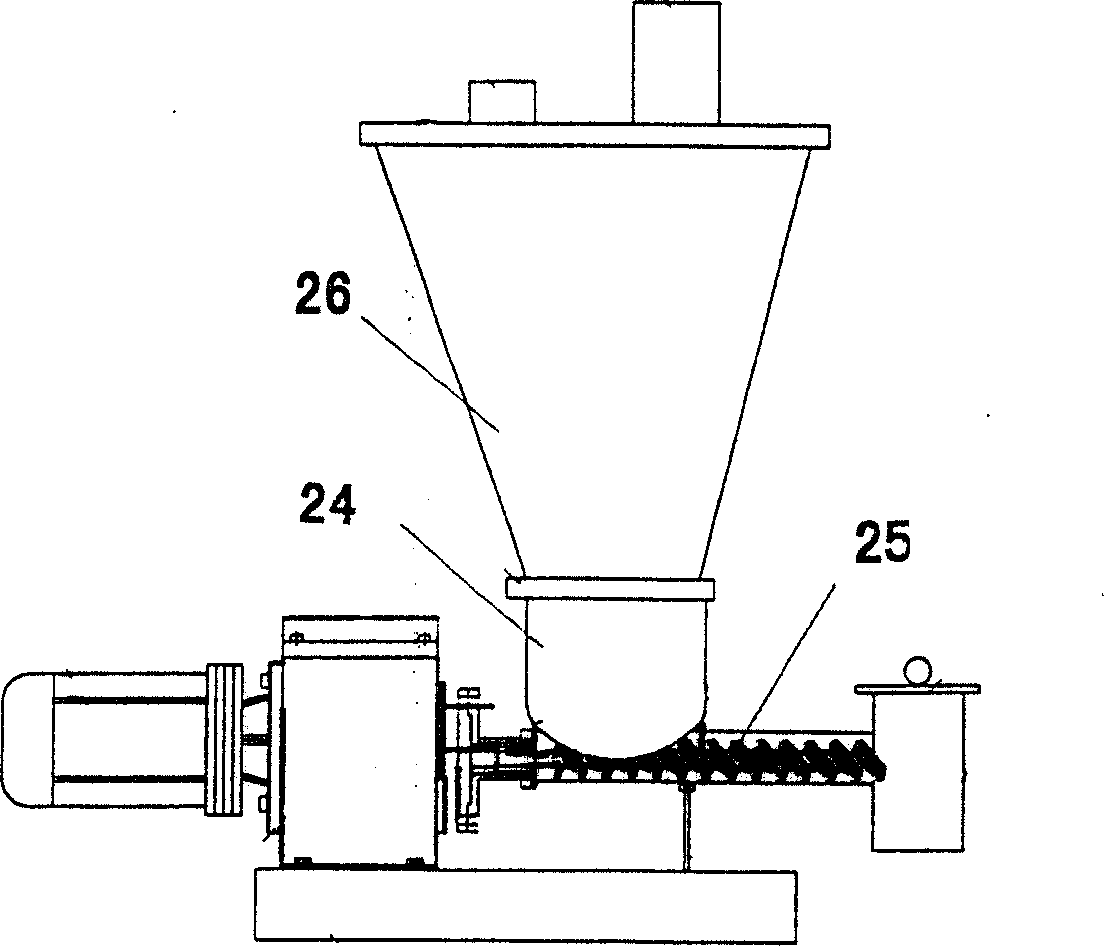

[0018] The weightless feeding machine of the present invention adopts the bus control mode, and the user inputs the corresponding proportioning parameters through the input device of the industrial computer, including the display of the industrial computer or a touch panel computer, including the mixing ratio of multiple groups of materials, which can be input separately, The total flow can also be input, and the proportion is automatically distributed. At the same time, the signal is transmitted to the PLC control system through the load sensor. After timely processing by the software program, the control system outputs a timely adjusted signal to the frequency converter, and the stability of the flow is realized through the motor, metering pump and other actuators.

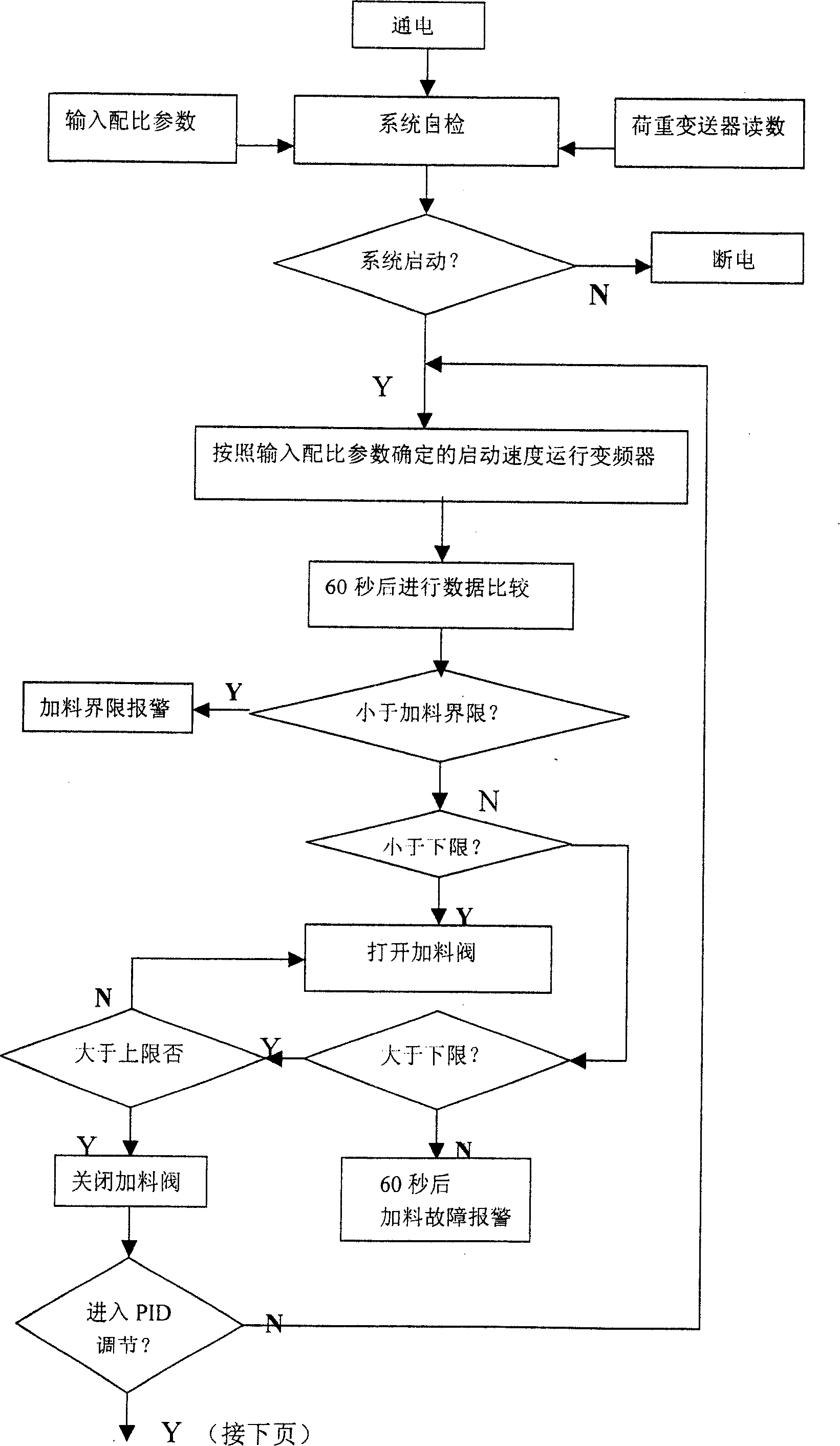

[0019] see Figure 2a with Figure 2b , in the metering and compounding method of the loss-in-weight feeder of the present invention, after the system is powered on, input the set proportioning parameters throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com