Foam extinguishing agent and manufacturing method thereof

A foam fire extinguishing agent and a technology for manufacturing method, which are applied in cleaning methods and utensils, chemical instruments and methods, fire protection equipment, etc., can solve the problems of fire extinguishing agent residue, affecting the accuracy of raw material proportioning, increasing the cleaning work of the reaction kettle, etc. Water flow resistance, reduce cleaning labor intensity, reduce the effect of sliding pipe jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

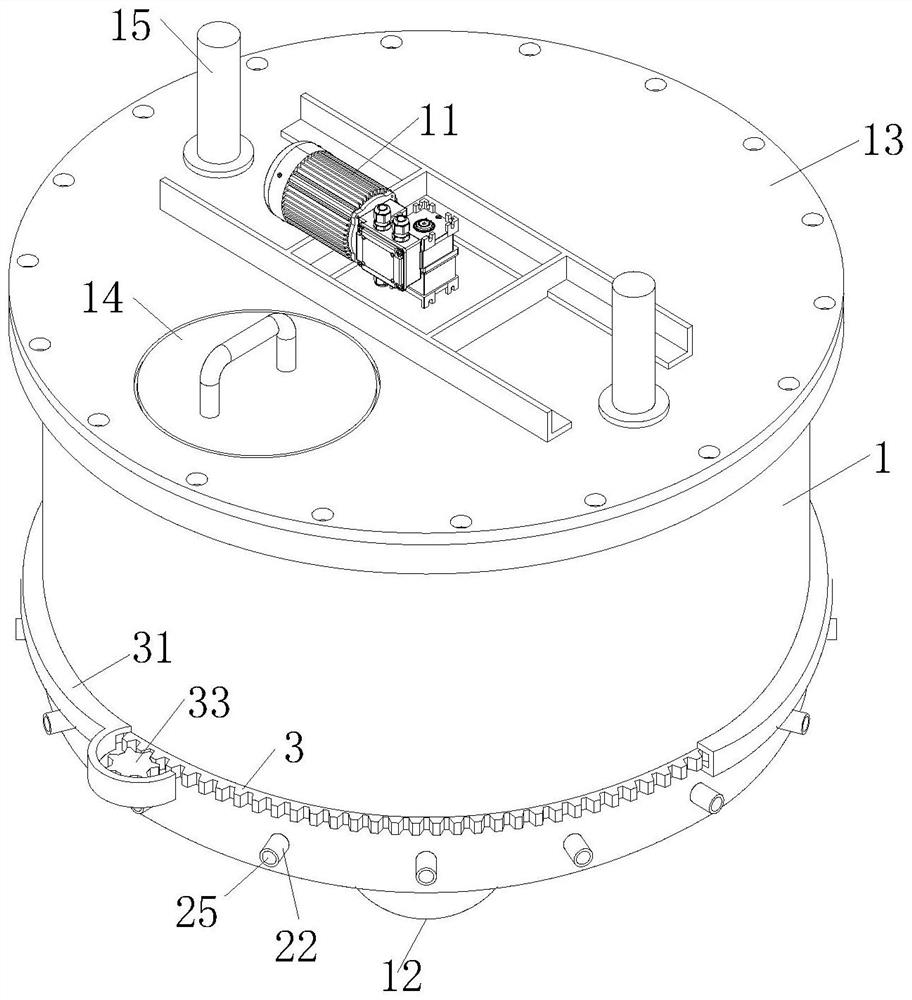

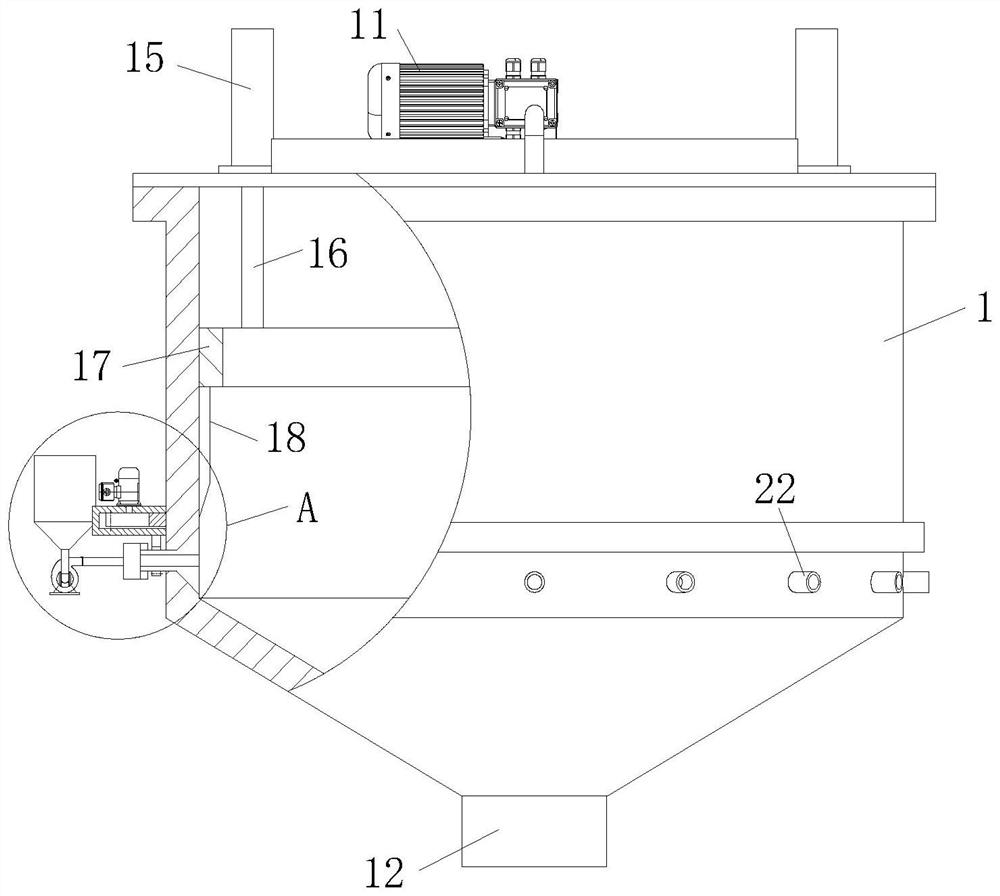

[0035] Such as Figure 1 to Figure 3 As shown, a kind of foam fire extinguishing agent described in the embodiment of the present invention consists of the following weight components: 3-5 parts of perfluorooctyl quaternary ammonium iodide, 2-3 parts of urea, 15-20 parts of blowing agent, 8-10 parts of sodium lauryl sulfate, 4-6 parts of catalyst, 12-15 parts of buffer, 45-50 parts of water, 3-6 parts of ethylene glycol.

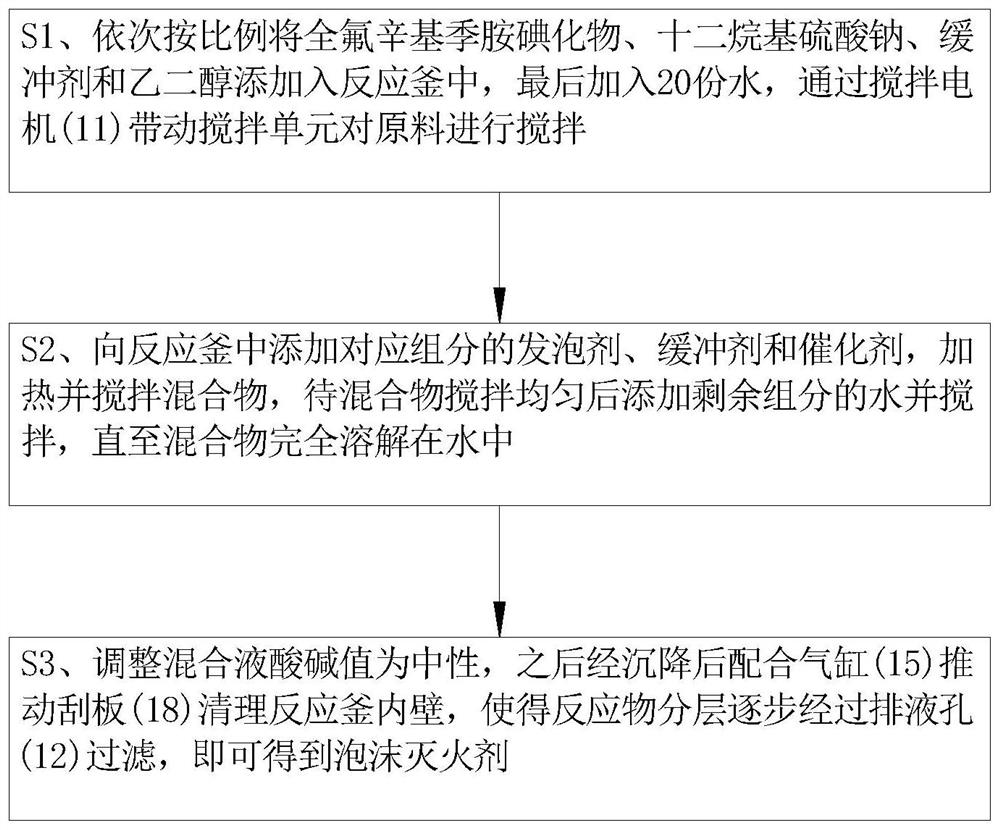

[0036] A kind of manufacture method of foam fire extinguishing agent, this method is used to manufacture above-mentioned foam fire extinguishing agent, comprises the following steps:

[0037] S1. Add perfluorooctyl quaternary ammonium iodide, sodium lauryl sulfate, buffer and ethylene glycol into the reaction kettle in sequence, and finally add 20 parts of water, and the stirring unit is driven by the stirring motor 11 to process the raw materials. stir;

[0038] S2. Add the foaming agent, buffer and catalyst of the corresponding components to the reactor,...

Embodiment 2

[0049] Such as Figure 7 As shown in Comparative Example 1, another embodiment of the present invention is: the round hole 2 is provided with a semi-circular water guide groove 5 near the upper position, and the inner walls of the water guide groove 5 near both ends are fixed by elastic ropes 51 There is a small ball 52; the water guide groove 5 is connected with a group of arc holes 53 close to the side of the sharp corner 19, and the end of the arc hole 53 close to the side wall of the sharp corner 19 is inclined downward; after the sliding rod 22 slides, the spray hole is driven 26 moves to the corresponding position of the circular hole 2, and then the water jetted from the spray hole 26 near the upper part passes through the water guide groove 5 and then jets out from the arc-shaped hole 53, further reducing the sediment accumulated between the adjacent scrapers 18, ensuring scraping The smooth closing of the plate 18 and the impact of the water flow on the small ball 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com