Green construction method of thickened cement ready-mixed mortar

A technology of ready-mixed mortar and construction method, which is applied in the direction of chemical instruments and methods, mixing plants, clay preparation devices, etc. It can solve the problems of time-limited use of wet-mixed mortar, segregation of dry-mixed mortar, and unsatisfactory effects, so as to ensure construction The effect of quality of results, reduction of engineering costs, and maximization of comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below with specific embodiment:

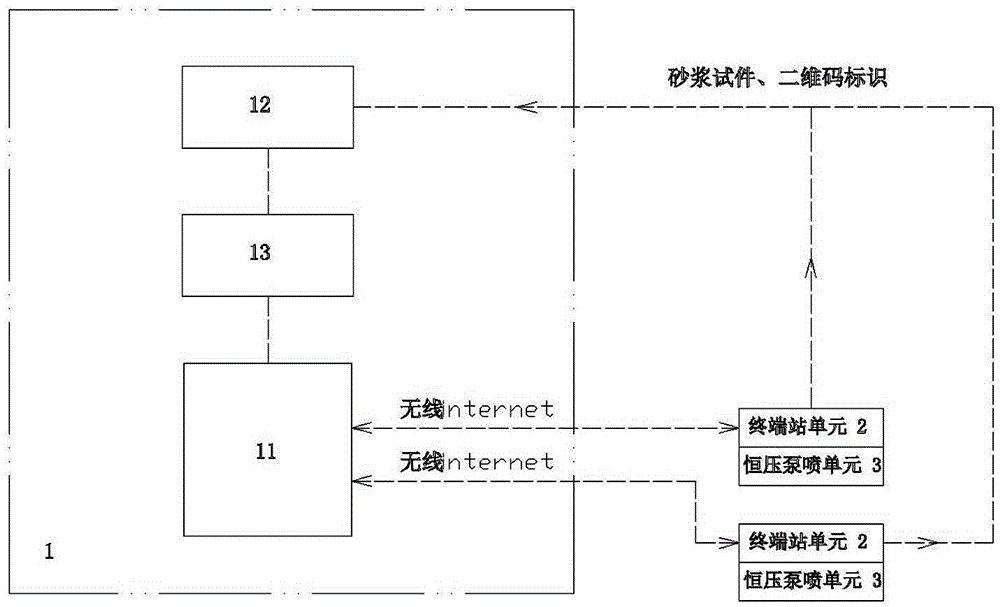

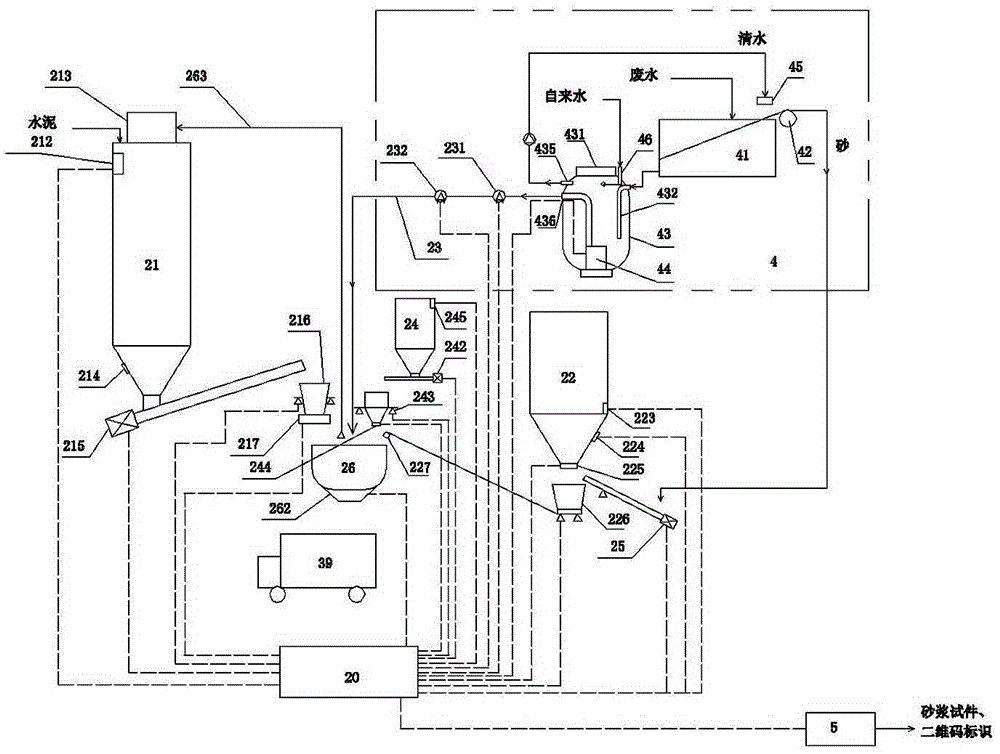

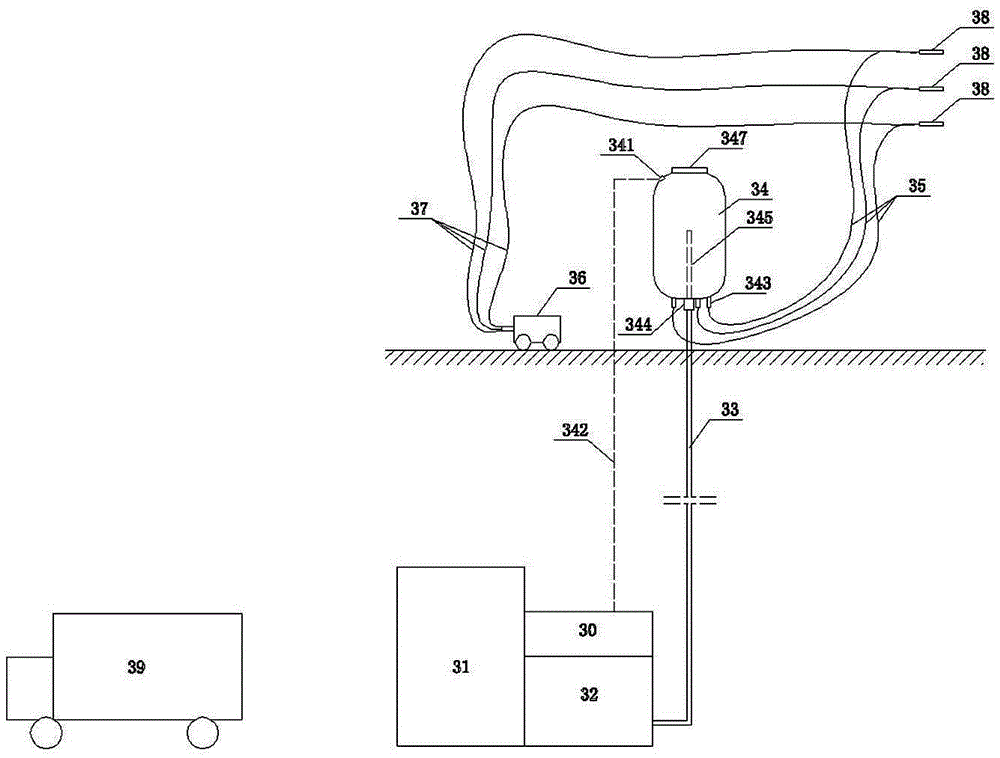

[0041] refer to figure 1 figure 2 and image 3 , a green construction method of thickened cement ready-mixed mortar, the equipment includes a central station unit 1, a terminal station unit 2, and a constant pressure pump spray unit 3; Thickened cement and prefabricated aggregates, the central station unit 1 controls and manages the terminal station unit 2 through the remote communication network, so that the terminal station unit 2 automatically prepares various types of mortar required for the project, and is pumped by the constant pressure pump spray unit 3 to The construction site conducts operations such as spray plastering and masonry grouting; the system tracks the quality of the mortar preparation and the whole construction process through the two-dimensional code identification management system, and the waste water and waste mortar from cleaning equipment are all reused in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com