Integrated adhesive making machine with automatic material distribution function

An automatic batching and integrated technology, which is applied in the field of integrated rubber making machines, can solve problems such as difficult cleaning, high waste rate, and large labor consumption, so as to achieve automatic and accurate batching, high degree of automation, and ensure the accuracy of the ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

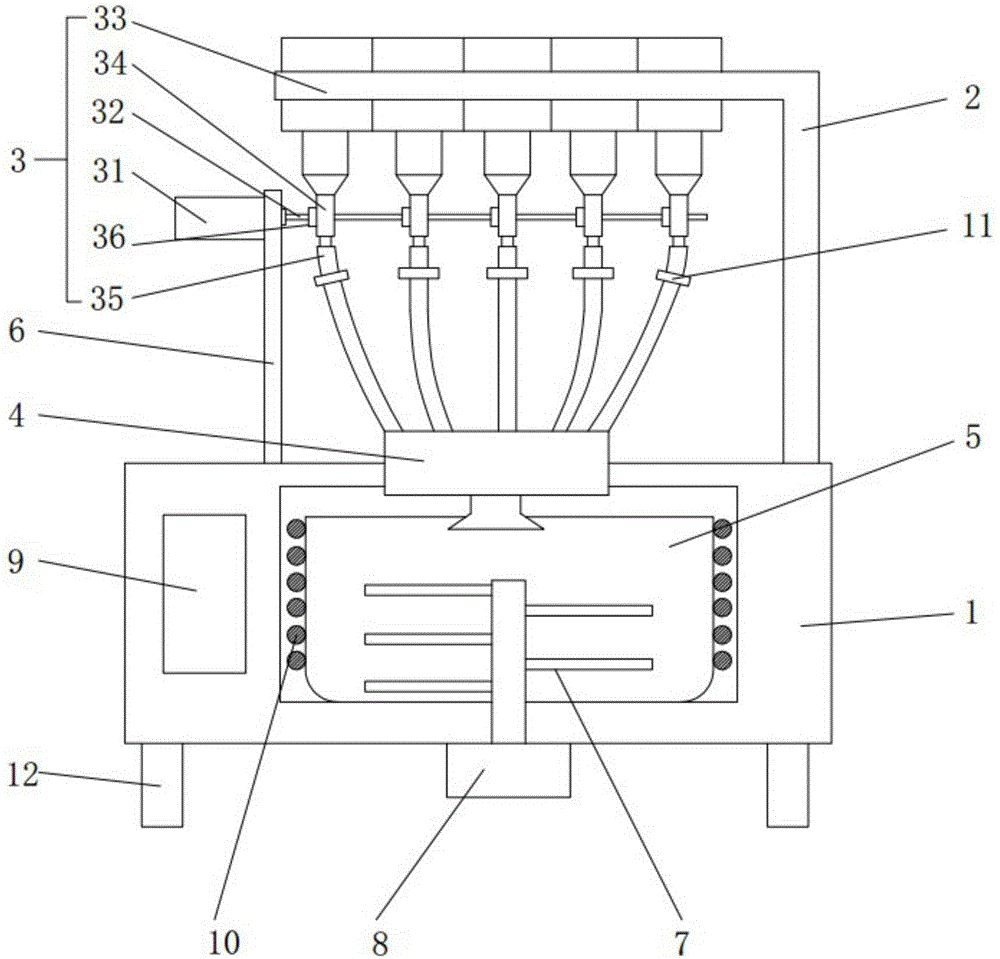

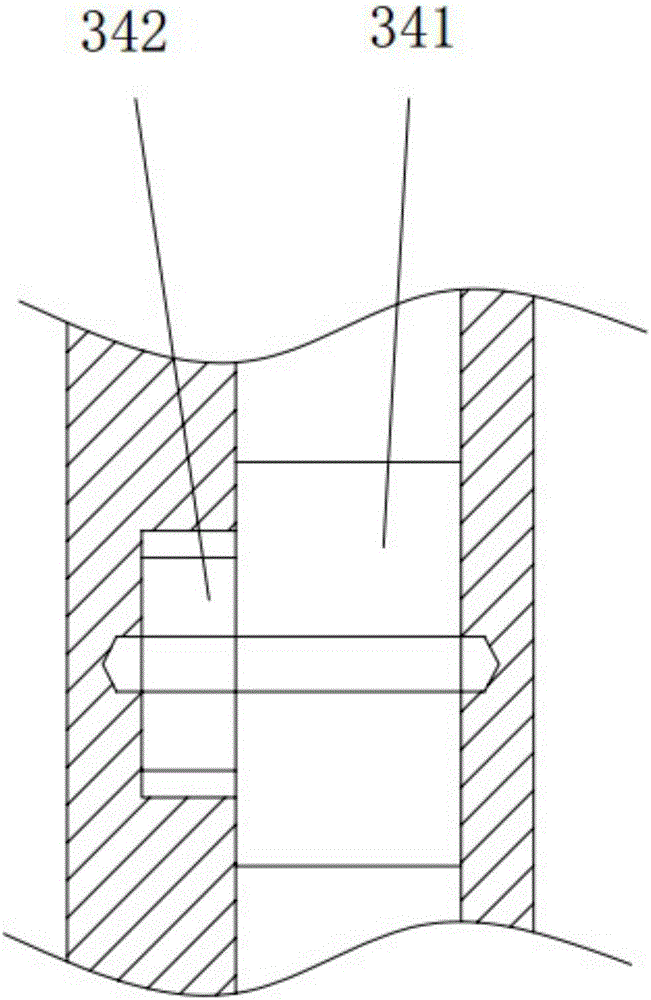

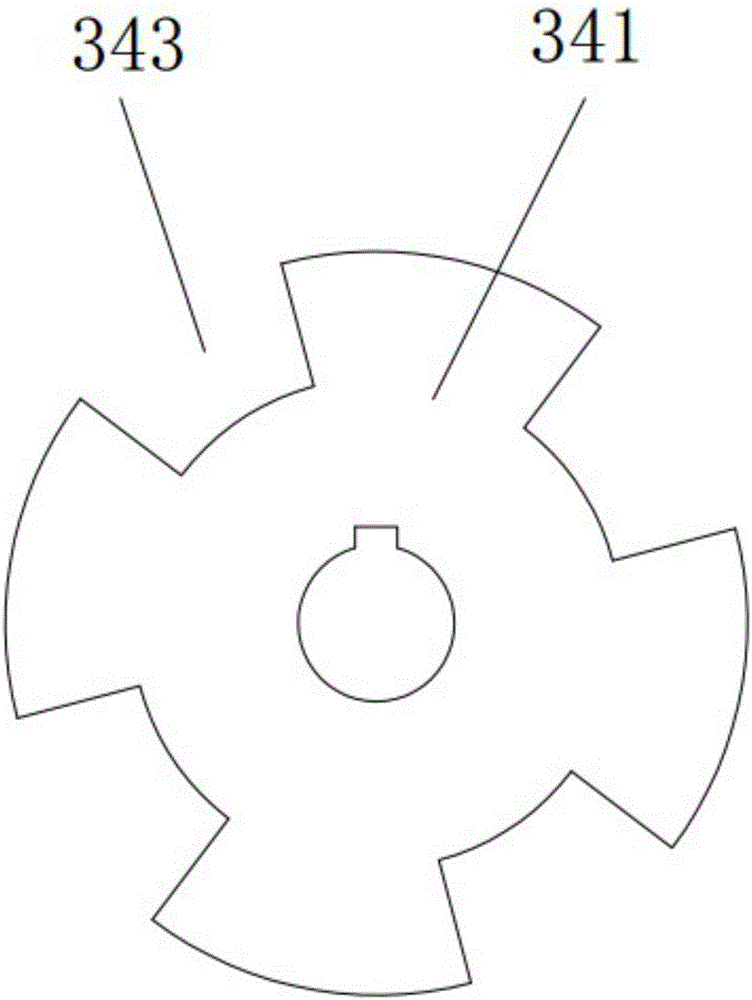

[0034] A kind of all-in-one glue making machine with automatic batching function according to the present invention, such as figure 1 As shown, it includes: a body 1; the body 1 is provided with a fixed frame 2; the fixed frame 2 is provided with a batching mechanism 3; the inside of the body 1 is provided with a vibrating screen 4 and a mixing cylinder 5; The vibrating screen 4 is arranged above the mixing cylinder 5; the batching mechanism 3 is composed of a group of batching units arranged side by side, a numerical control drive motor 31 and a hexagonal transmission shaft 32; material storage box 33, discharger 34 and feeding pipe 35; the feeding pipe 35 is connected with the vibrating screen 4; material alarm 11; in addition, the side of the discharger 34 is provided with a speed governor 36; the transmission shaft 32 is sequentially set in the middle of each speed governor 36, and one end is connected to the output shaft of the numerical control drive motor 31 Connect; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com