Polyurethane foam plastic slabbing machine

A technology of foamed plastics and polyurethane, which is applied in metal processing and other directions, can solve the problems that it is difficult to meet the speed requirements of emergency disposal, and can not meet the speed requirements of emergency disposal, etc., and achieve the effect of fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

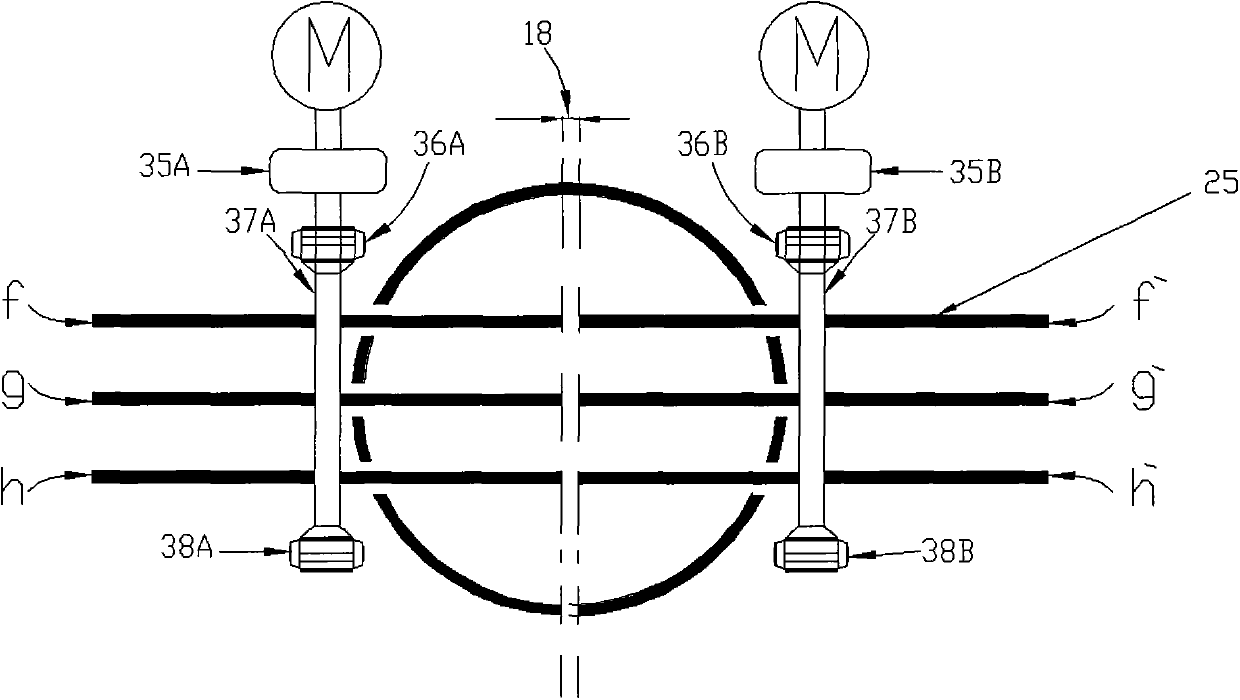

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

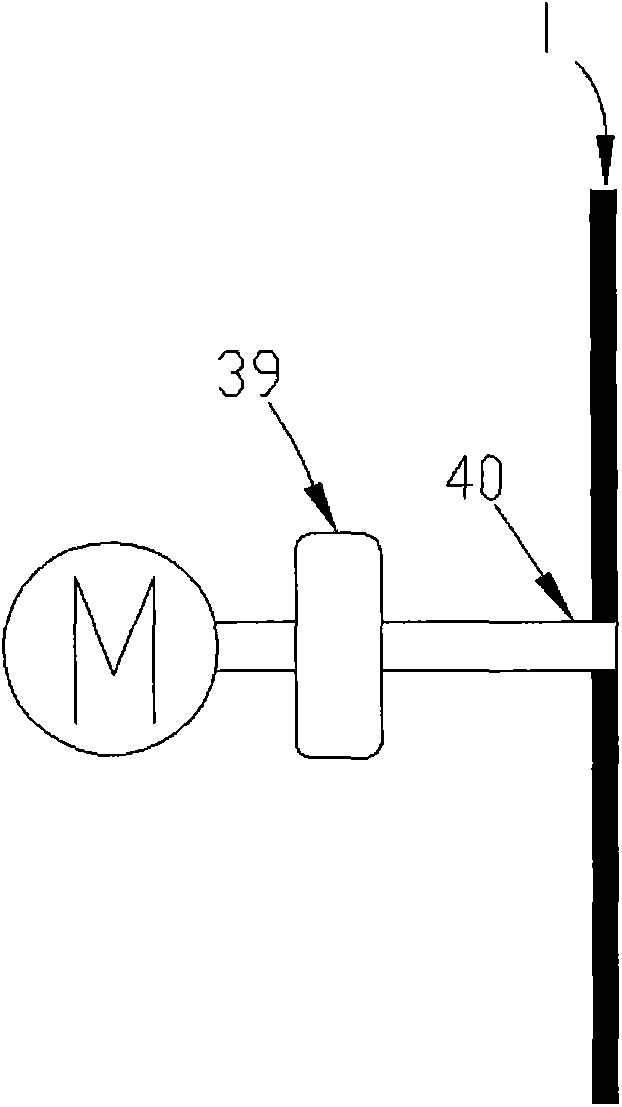

[0039] Such as Figure 1 to Figure 4 As shown, the feeding barrel 1 is a cylinder with an inner diameter of 300mm and a wall thickness of 1.5mm.

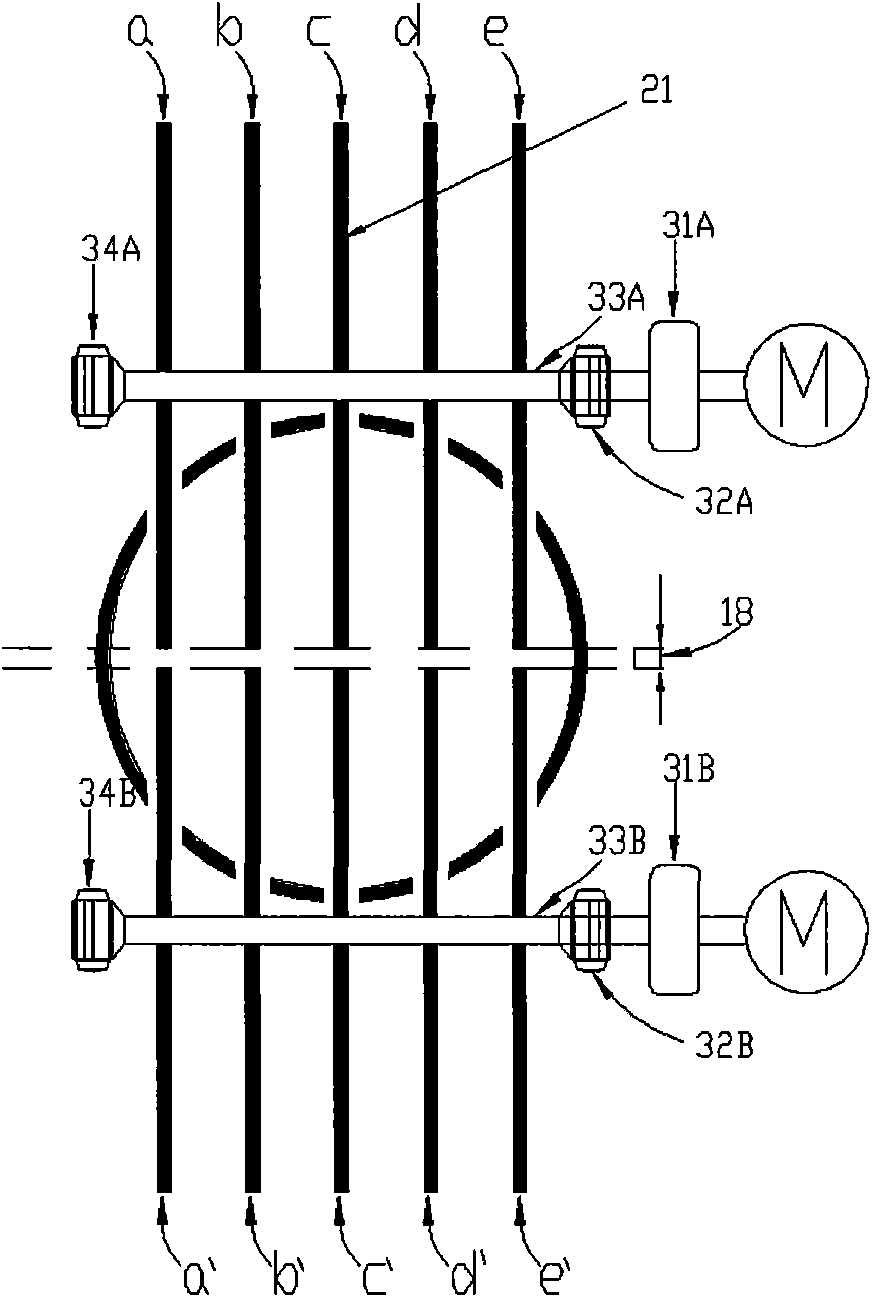

[0040] The vertical knife group 2 includes two groups of grille garden knives, each set of grille garden knives includes five circular saws with a diameter of 350mm, the thickness of the sawtooth is 3.2mm, the thickness of the disc is 1.8mm, and the distance between the circular saws is 50mm, parallel to each other and fixed on On a rotating shaft with a diameter of 50 mm, bearings are installed at both ends of the rotating shaft, and a shaft coupling is installed at one end of the bearing outside.

[0041]In order to ensure the stability of the vertical knife group 2 when it is working, heat treatment is carried out on the rotating shaft, and the end faces of the fixing ring and the nut are finel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com