Quick-dry ink jet printing ink for coated paper and preparation method of quick-dry ink jet printing ink

A technology of inkjet ink and coated paper, which is applied in the field of quick-drying inkjet printing ink, can solve the problems of printing ink such as poor adsorption capacity, ink flow, loose ink, etc., and achieve the effect of good printing quality and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

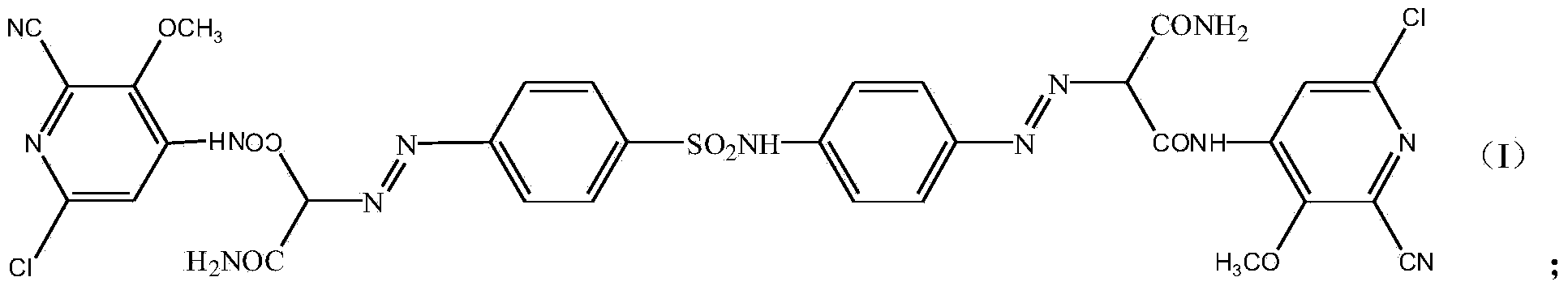

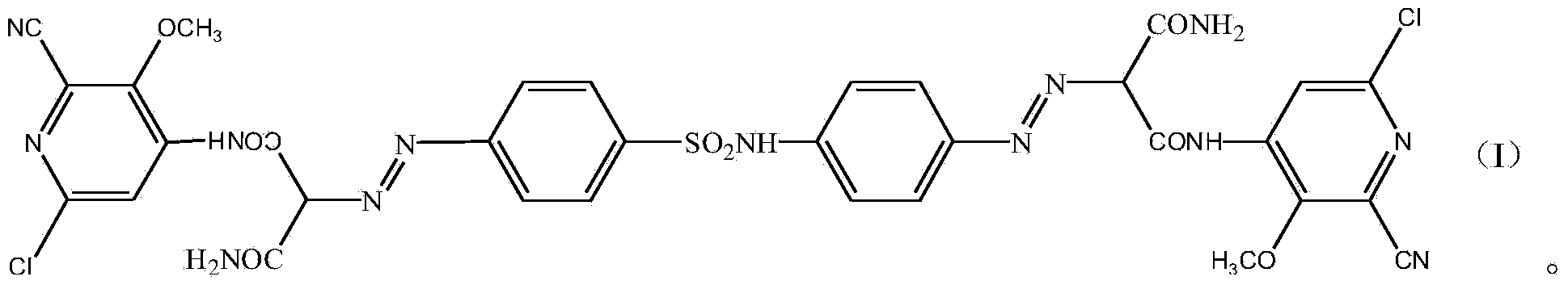

Image

Examples

Embodiment 1

[0012] First, 1.3g C.I. direct black 166, 2.0g pigment, 5.6g water-soluble acrylic resin, 10g glycerin, 8g1,3-dimethyl-3-imidazolinone, 13g diethylene glycol, 1.5g nonionic surfactant surfynol465 , 3.5g urea, 1g triethylene glycol monobutyl ether, 2g antifungal agent, add 80g deionized water, heat and stir at 80-90°C for 1h, cool to 35-40°C, add 2.5g ethanol, stir at 25-30°C for 20min, Stand still for 10 hours, and vacuum filter with a membrane with a pore size of 0.3 μm to obtain a quick-drying inkjet printing ink.

Embodiment 2

[0014] First, 1.8g C.I. direct black 168, 2.3g pigment, 7.0g water-soluble acrylic resin, 15g glycerin, 7g1,3-dimethyl-3-imidazolinone, 12g diethylene glycol, 1.5g nonionic surfactant surfynol465 , 3.3g urea, 1.5g triethylene glycol monobutyl ether, 4.5g antifungal agent, add 85g deionized water, heat and stir at 80~90℃ for 1.5h, cool to 35~40℃, add 3g ethanol, stir at 25~30℃ After 20 minutes, stand still for 12 hours, and vacuum filter with a membrane with a pore size of 0.35 μm to obtain a quick-drying inkjet printing ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com