Method of promoting aging of white spirit

An aging and liquor technology, applied in the field of winemaking, can solve the problems of inability to meet consumers' demand for liquor quality, occupying a lot of containers, and large loss of liquor, so as to shorten the aging time, improve the quality, and improve the concentration and purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

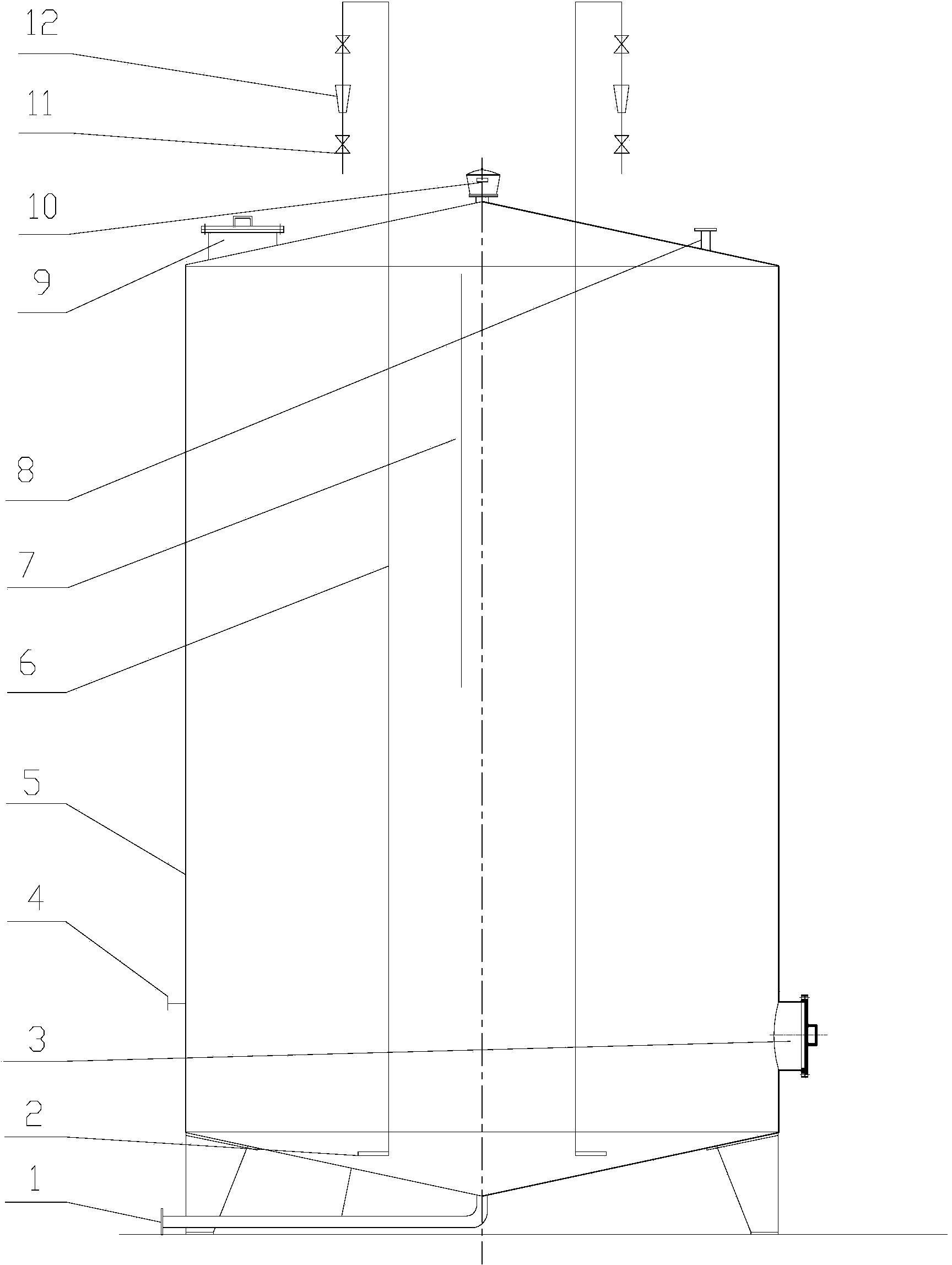

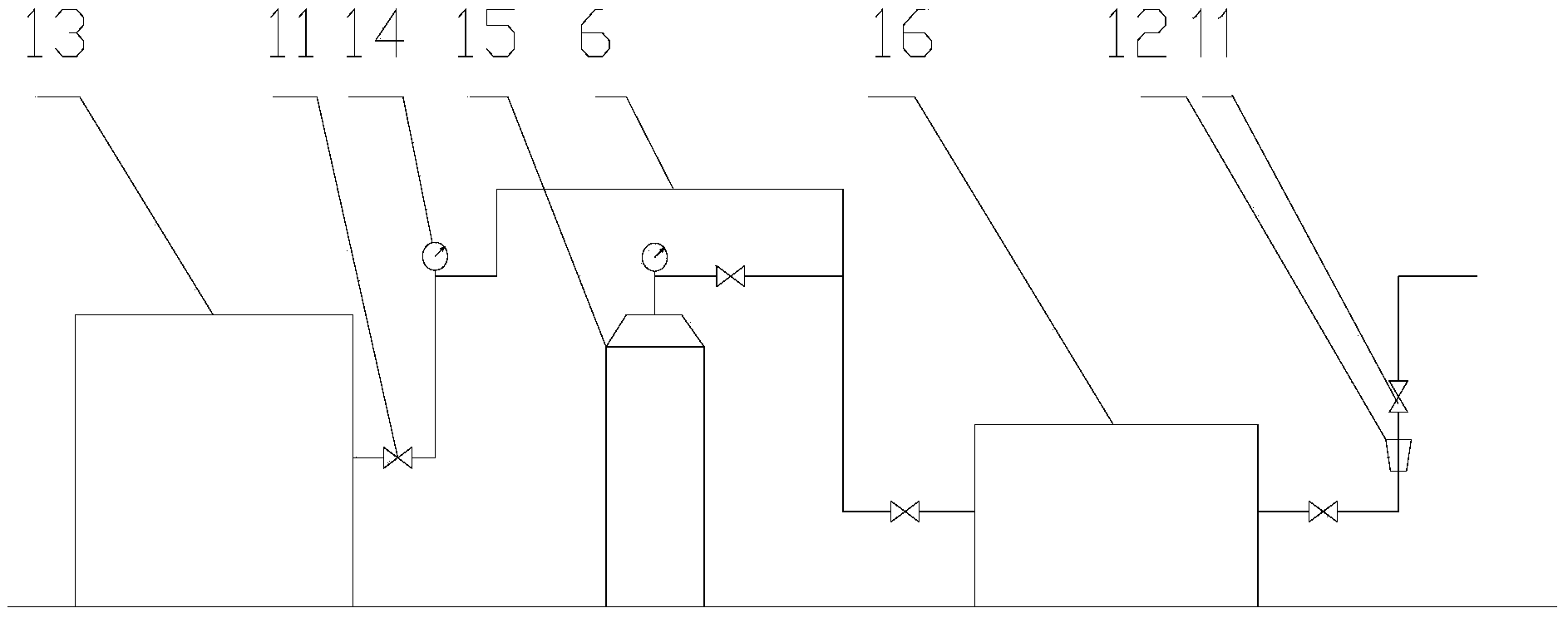

[0036] Store 100 tons of 33-degree Luzhou-flavor wine liquid to be processed in a closed wine storage tank, and continuously inject clean ozone generated by pure oxygen as an oxygen source into the wine liquid, and the ozone is evenly distributed in the wine liquid through a gas distributor , wherein the amount of ozone fed is 5L / ton of wine, and the flow of ozone fed is 8L / min. After completing the ozone treatment, carry out feeding into dust-free and oil-free air treatment, the amount of feeding air is 10L / ton of liquor, and the feeding flow rate of the air is 10L / min. After the wine liquid is processed, it is stored for 24 hours and then sampled for taste evaluation and physical and chemical testing. After the indicators meet the requirements, it can be filtered and packaged as a finished product.

Embodiment 2

[0038] Store 100 tons of 33-degree rice-flavored wine liquid to be processed in a closed wine storage tank, and continuously inject clean ozone generated by pure oxygen as an oxygen source into the wine liquid, and the ozone is evenly distributed in the wine liquid through a gas distributor , where the amount of ozone fed is 3.5L / ton of wine, and the flow of ozone fed is 5L / min. After completing the ozone treatment, carry out the treatment of feeding dust-free and oil-free air, the amount of feeding air is 8L / ton of liquor, and the feeding flow of the air is 7L / min. After the wine liquid is processed, it is stored for 24 hours and then sampled for taste evaluation and physical and chemical testing. After the indicators meet the requirements, it can be filtered and packaged as a finished product.

Embodiment 3

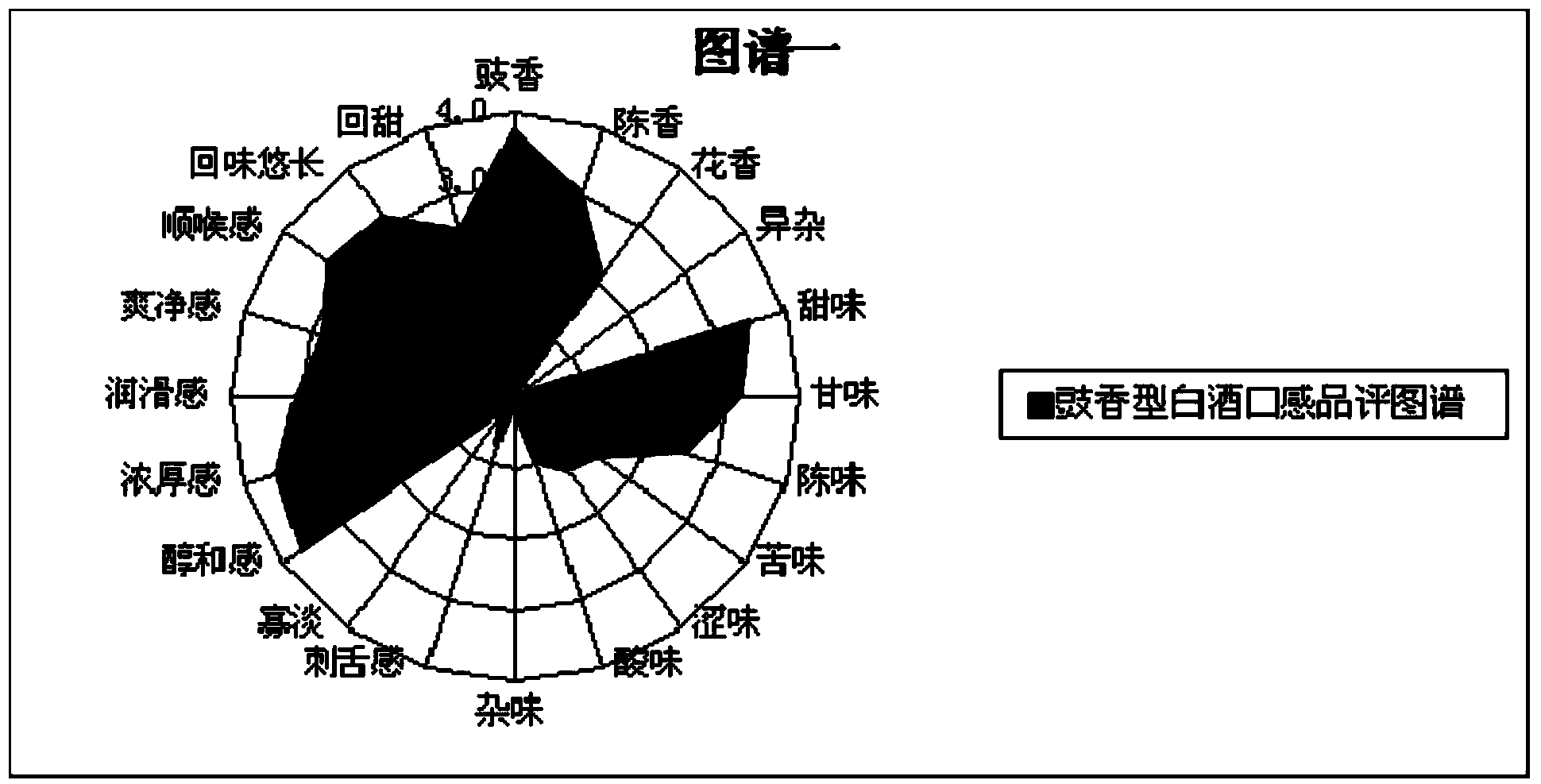

[0040]Store 100 tons of soy-flavored wine to be processed in a closed wine storage tank. The temperature of the wine liquid is 30°C. Pure oxygen is continuously introduced into the wine liquid as an oxygen source to generate clean ozone. The ozone is evenly distributed in the In the wine liquor, wherein the amount of ozone fed is 2L / ton of wine liquor, and the feed flow of the ozone is 5L / min. After completing the ozone treatment, carry out the treatment of feeding dust-free and oil-free air, the amount of feeding air is 8L / ton of liquor, and the feeding flow of the air is 10L / min. After the wine liquid treatment is completed, after 3 days of storage, samples are taken for taste evaluation and physical and chemical testing. After the indicators meet the requirements, the subsequent meat soaking treatment can be carried out.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap