Combined road guardrail

A combined, road-based technology, applied in the direction of roads, roads, road safety devices, etc., can solve the problems of passers-by and motor vehicle drivers, such as complex transportation, inconvenient installation, and unfavorable perspective of motor vehicle drivers. Reduce daily maintenance costs, facilitate viewing angles, and improve connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

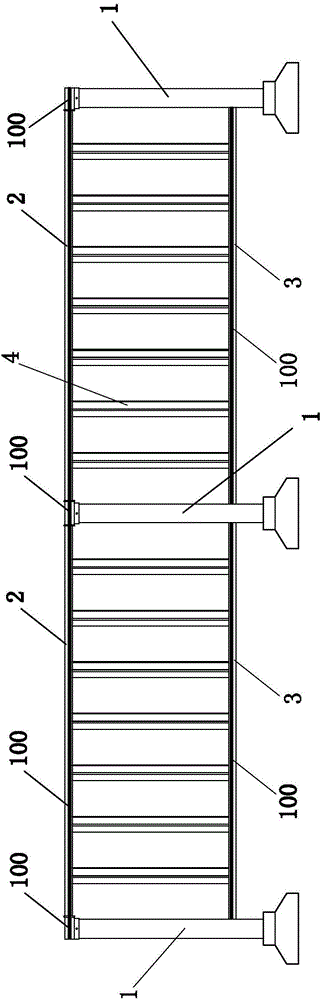

[0053] see figure 1 , the present embodiment takes two guardrail units as an example, including three columns 1, two upper rails 2, two lower rails 3 and two sets of vertical bars 4, each group of vertical bars has seven. Column 1 includes two side columns and a middle column. The column 1, the upper cross bar 2, the lower cross bar 3 and the vertical bar 4 are all made of aluminum alloy. Column 1, upper rail 2, lower rail 3 and vertical bar 4 are all hollow structures, wherein column 1 is provided with jacks suitable for inserting lower rail 3, and upper rail 2 and lower rail 3 are also provided with There are ribs.

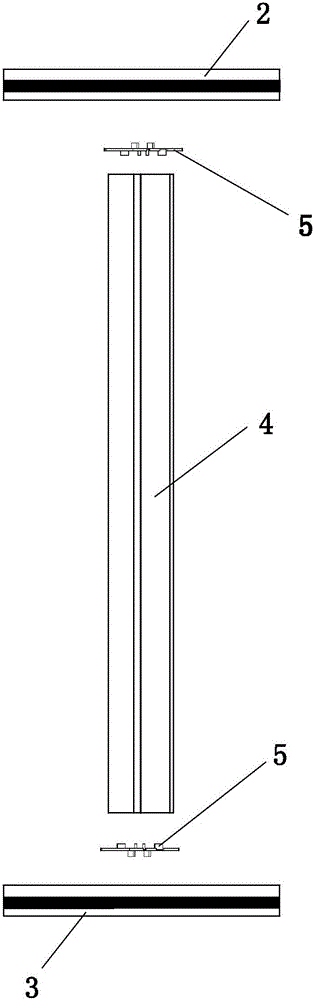

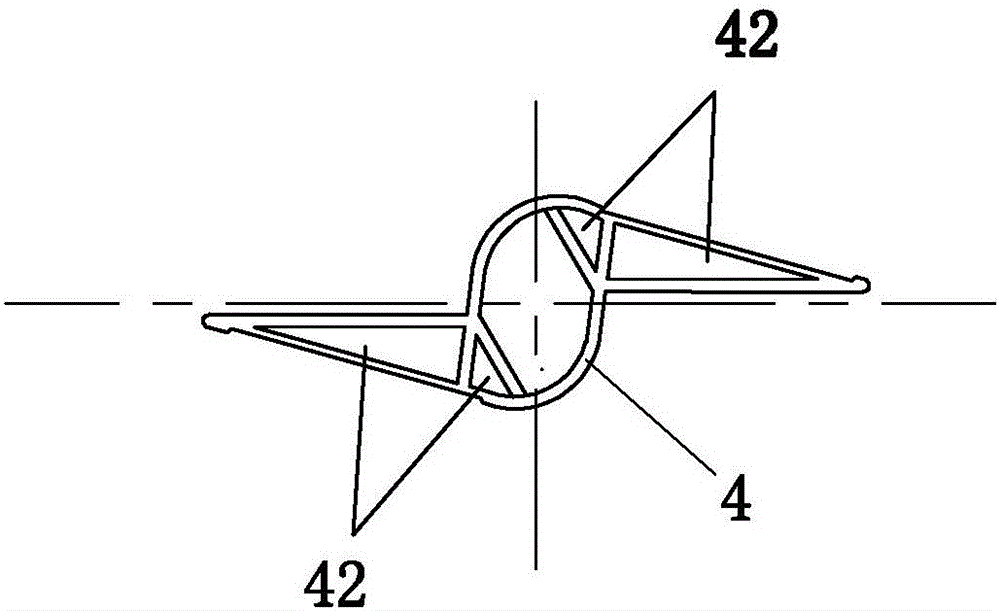

[0054] see figure 2 and image 3 The vertical bar 4 is a hollow structure with four through holes 42, and the upper and lower ends of the vertical bar 4 are connected with the upper cross bar 2 and the lower cross bar 3 through a stamping connector 5.

[0055] see Figures 4-1 to 4-4 The stamped connector 5 includes a main body 51 and inner protrusions 52...

Embodiment 2)

[0063] See Figure 13 to Figure 16 , the guardrail of this embodiment is basically the same as that of Embodiment 1, the difference is that: among the vertical rods 4 between the two columns 1, the two vertical rods 4 at both ends and the vertical rod 4 in the middle pass through the fixing assembly 8 is fixed between the upper cross bar 2 and the lower cross bar 3.

[0064] The fixing assembly 8 includes a steel pipe 81 , a threaded sleeve 82 , a square sleeve 83 and a fastening screw 84 .

[0065] The steel pipe 81 can be a round steel pipe or a square steel pipe, and this embodiment is a round steel pipe.

[0066] The upper end of steel pipe 81 is welded and fixed with square sleeve 83, and the upper surface of square sleeve 83 is suitable for inserting in the stamping hole of upper cross bar 2, and the lower end of steel pipe 81 is provided with external thread, and the upper end of threaded sleeve 82 is provided with steel pipe 81 lower end. The external thread is compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com