Well drilling top drive running casing tool driving head

A driving head and casing technology, which is applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of high processing precision of hydraulic components, lower cost and manufacturing difficulty, and high technical level requirements, and achieve easy Remote control, reduced processing difficulty, low operator requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

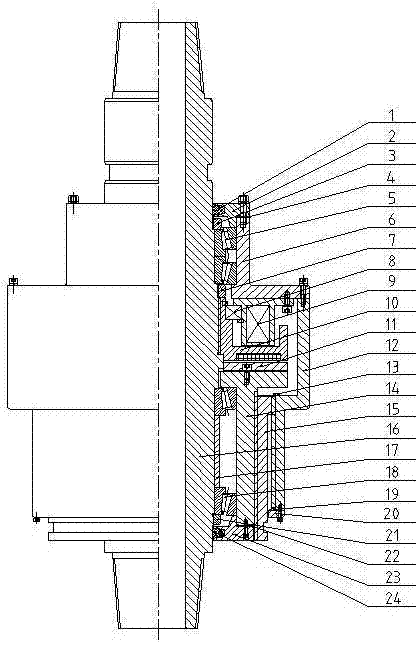

[0011] Embodiment 1: The present invention will be further described in detail by taking the drive head of the casing driving tool driven externally as an example.

[0012] Apply the present invention to the drive head of an external top drive casing tool, such as figure 1 As shown, a driving head of a drilling top drive casing running tool uses electromagnetic brake technology to convert the torque on the main shaft 16 into thrust to realize the clamping of the casing by the slip clamping mechanism. The key structures include a shell, a torque Transmission mechanism, torque conversion mechanism and auxiliary mechanism, etc. The shell is mainly composed of upper felt washer 1, upper shaft end retaining ring 2, upper adjusting gasket 4, upper housing 6, upper tapered roller bearing group 5, lower housing 12, lower felt washer 24, lower shaft end retaining ring 23. The lower adjusting gasket 22 is composed; the torque transmission mechanism mainly consists of an electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com