Roller bearing nut screw pair

A roller and screw technology, applied in belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems such as insufficient positioning accuracy of nut-screw pair, large frictional resistance, complex processing technology, etc. Insufficient length of processing equipment, reduced friction loss, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and examples.

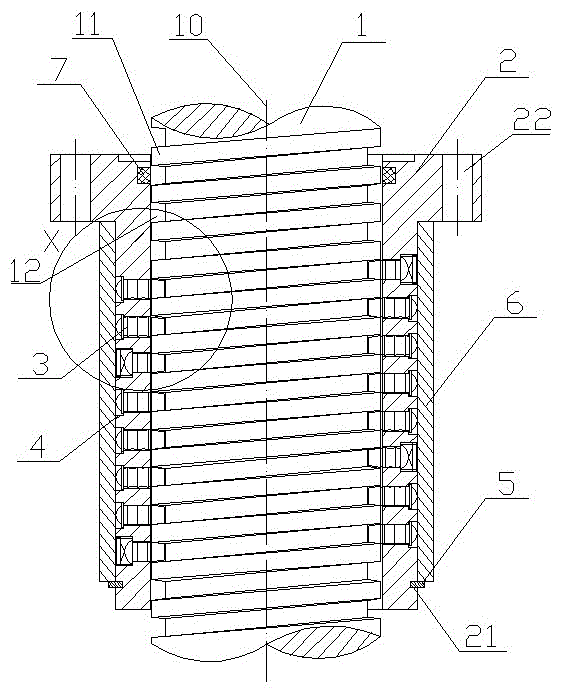

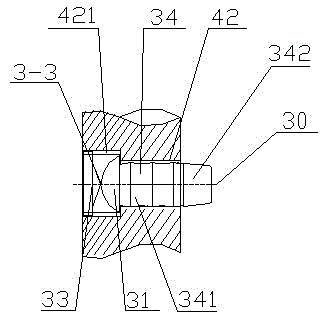

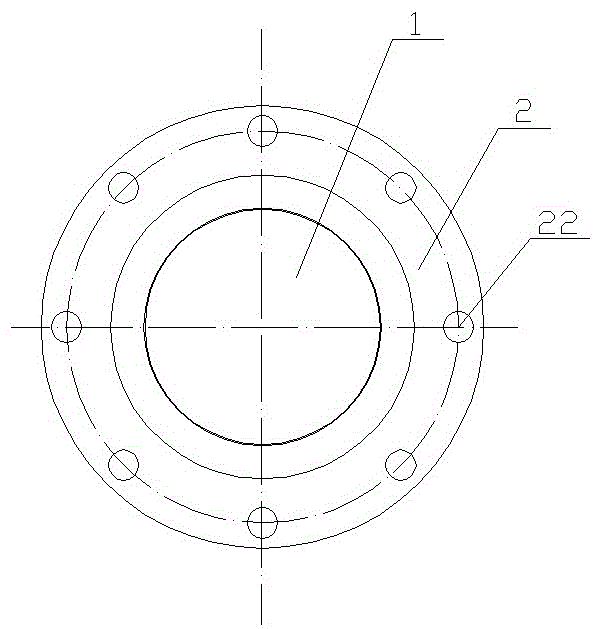

[0046] see Figure 1-Figure 16 , This embodiment includes a screw 1, a nut 2, a roller 3, a roller hole 4, a circlip 5, an outer ring 6 and a dustproof device 7.

[0047] In this embodiment, the center of the nut 2 has a circular through hole and the inner wall of the nut 2 has no internal thread, and the cylindrical screw 1 penetrates into the nut 2; the screw 1 has an external thread, and the concave part of the external thread is a tooth The groove 11 and the protruding part are the tooth body 12. The maximum outer diameter D of the screw rod 1 (that is, the outer diameter of the top of the tooth body 12) is slightly smaller than the inner diameter of the nut 2. The tooth groove 11 forms a spiral track as a whole, and the tooth groove 11 and the tooth body 12 section (such as figure 1 shown) are isosceles trapezoidal, and the tooth profile angle α is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com