Composite type seal pneumatic door

A sealing gas and composite technology, applied in the direction of sliding valves, engine components, valve details, etc., can solve problems such as hot air can not be isolated, personal accident hazards, total friction increase, etc., to protect the surrounding environment of equipment, improve service life, airtight Sexual Enhancement Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

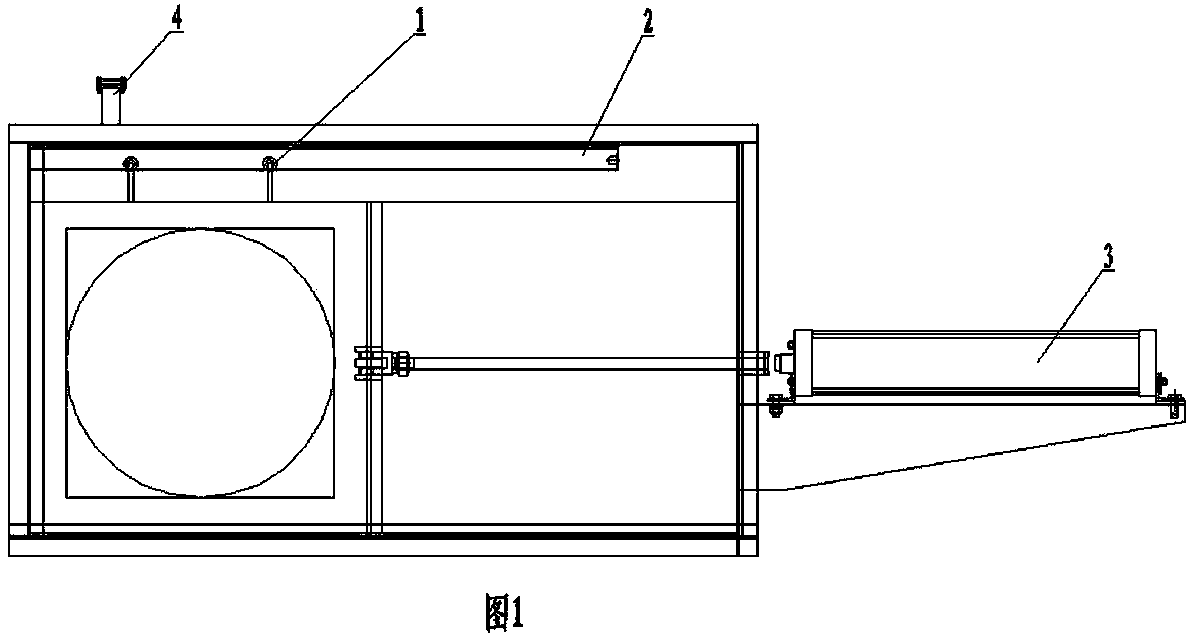

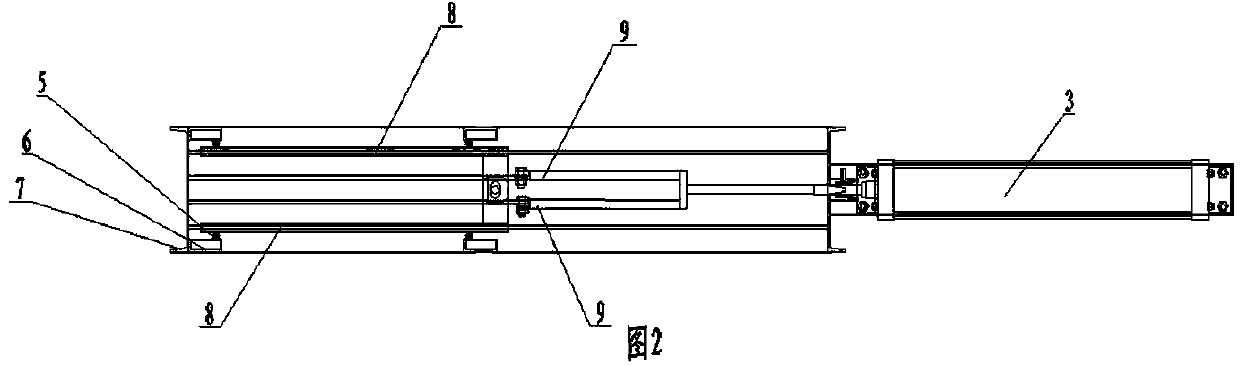

[0019] like figure 1 , figure 2 As shown, a composite sealed pneumatic door includes guide wheel 1, guide rail 2, opening and closing cylinder 3, sealing inflation device 4, packing 5, sealing frame 6, shell frame 7, wear-resistant baffle 8, independent The double-track baffle 9 and other structures are characterized in that: the guide wheel 1 is fixed on the guide rail 2, the sealing and inflating device 4 is located on the upper side of the sealing frame 6, the packing 5 is located on the edge of the sealing frame 6, and the sealing frame 6 is placed on the shell frame 7, wear-resistant baffles 8 and independent double-track baffles 9 are placed along the corresponding guide rails 2.

Embodiment 2

[0021] like figure 1 , figure 2 As shown, the wear-resistant baffle 8 has two layers, which are respectively on both sides of the independent double-track baffle 9 .

Embodiment 3

[0023] like figure 1 , figure 2 As shown, the independent double track baffle plate 9 is located in the middle of the housing frame 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com