Fast pneumatic valve

A pneumatic valve, fast technology, applied in valve details, valve devices, engine components, etc., can solve the problems of poor low-speed performance of air cannons, unguaranteed air cannon accuracy, increased design pressure, etc., to achieve smooth motion and improve stress. , the effect of improving the low speed capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment and accompanying drawing, the present invention is further described:

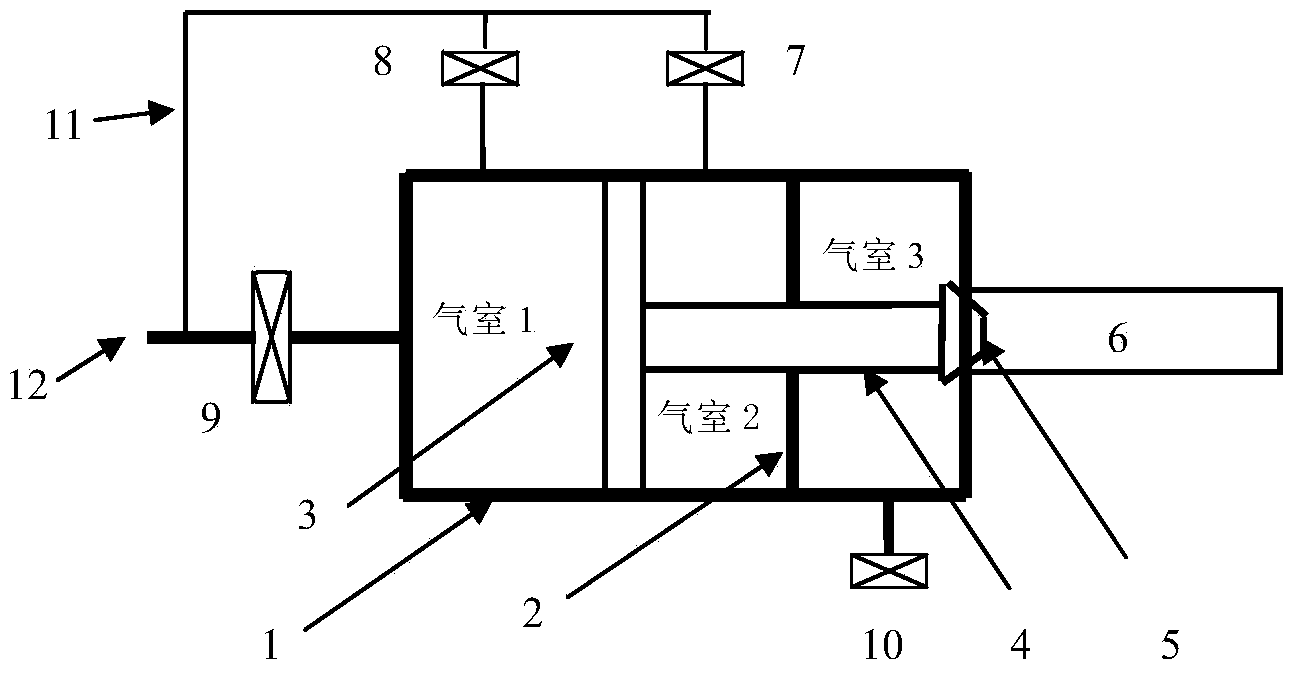

[0018] see figure 1 , which is a structural schematic diagram of the fast pneumatic valve of the present invention. The fast pneumatic valve includes a valve body, a cone valve, a solenoid valve, a partition, and a gun barrel. Among them, the cone valve and the partition are arranged in the valve body, the piston of the cone valve and the valve body are separated from the air chamber 1 (the first air chamber), the valve head of the cone valve passes through the partition and can cooperate with the nozzle of the gun barrel, the cone valve The space between the diaphragm and the valve body is the air chamber 2 (the second air chamber), the space between the diaphragm and the valve body is the air chamber 3 (the third air chamber), and the air chamber 1 communicates with the outside atmosphere, and the air chamber 3 Connects to the main chamber for firing the barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com