On-line measurement device for shallow-spigot part with shaft in middle

A technology of measuring device and stop, which is applied in the direction of mechanical diameter measurement, etc., to achieve the effect of simple structure, high measurement accuracy, and filling technical gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

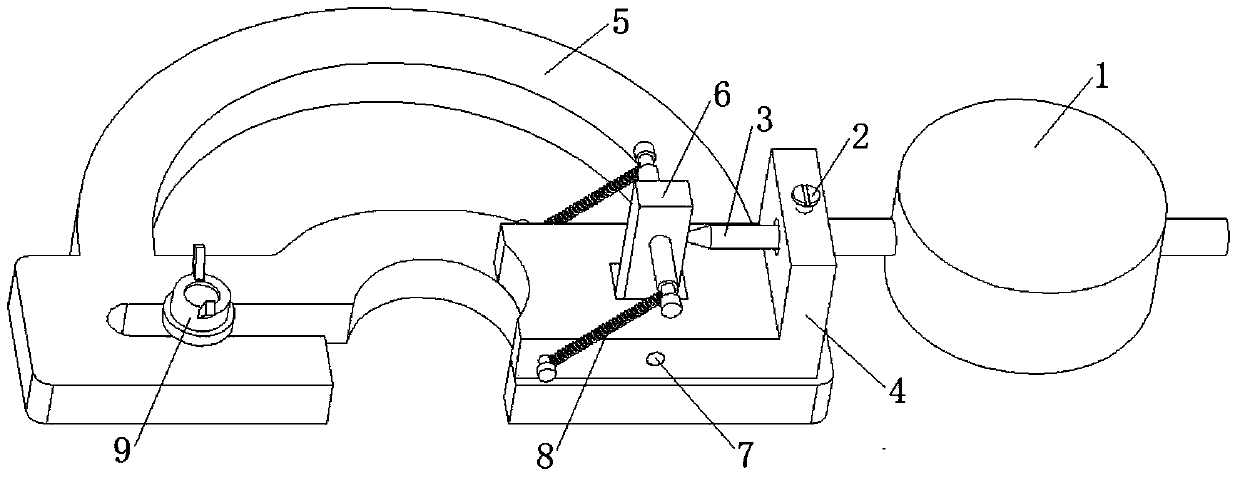

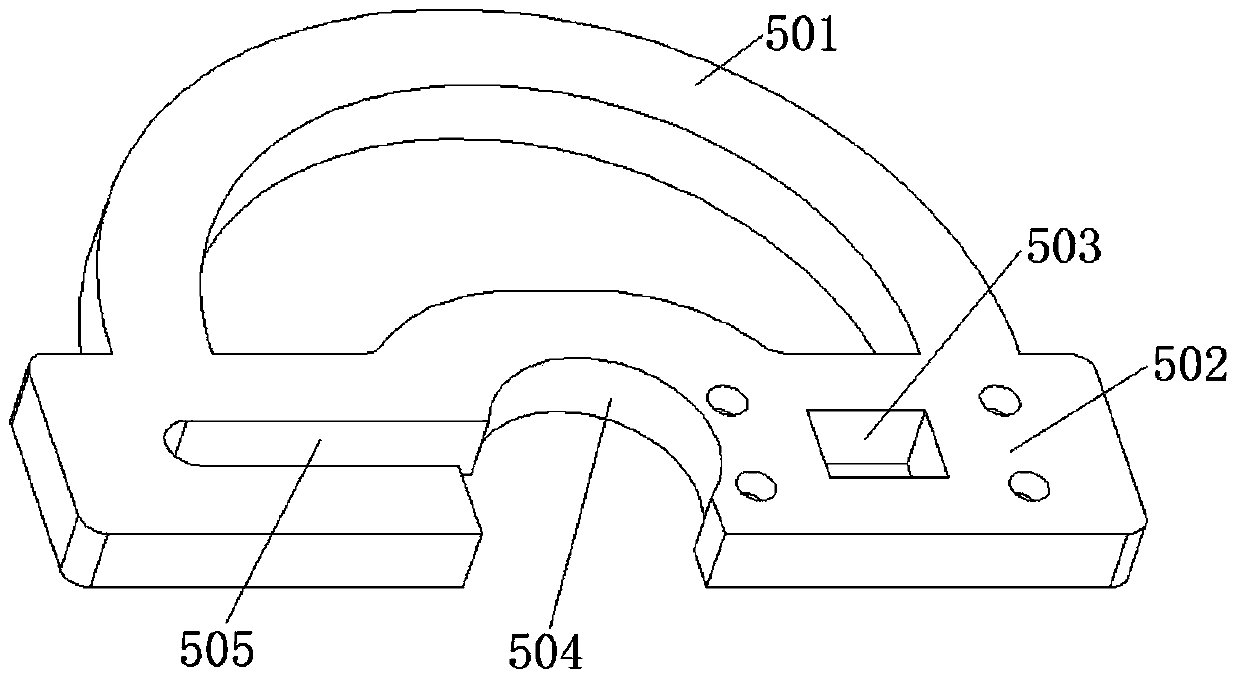

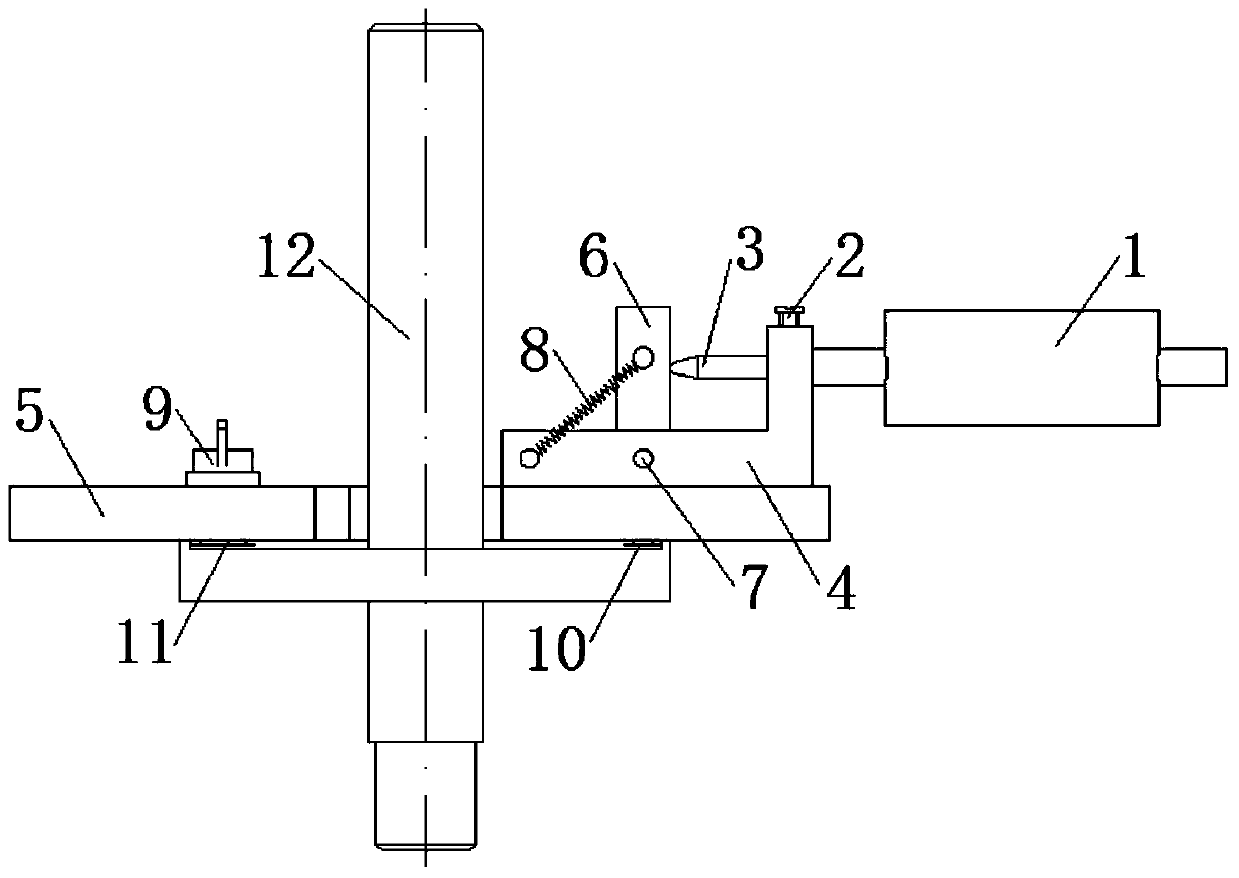

[0033] to combine figure 1 , figure 2 and image 3, a kind of on-line measuring device used for shallow seam parts with a shaft in the middle of this embodiment includes a bracket 5 and a measuring mechanism installed on the bracket 5. The measuring mechanism includes a measuring instrument 1, a fixed frame 4, a lever 6, a pin Shaft 7, tension spring 8, slider 9, floating stylus 10 and fixed stylus 11, measuring instrument 1 is dial indicator or dial indicator, the measurement accuracy of dial indicator can reach 0.01mm, and the measurement accuracy of dial indicator It can reach 0.001mm. Specifically, in this embodiment, in order to make the measurement accuracy higher, the measuring instrument 1 uses a dial indicator. The fixed frame 4 is provided with a through hole for installing the lever 6, the lever 6 passes through the above-mentioned through hole, and is hinged in the through hole through the pin shaft 7, and the tension spring 8 is obliquely placed between the lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com