A method for measuring the median diameter of particles in diesel engine exhaust

A measurement method, diesel engine technology, applied in the field of measurement, can solve the problems of complex measurement equipment, failure to reflect the size of individual particles, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] specific implementation plan

[0061] Describe the present invention below in conjunction with specific embodiment:

[0062] Step 1: Collect samples of particles to be tested;

[0063] The engine combustion particles in the main exhaust passage of the engine are collected by a filter membrane as the particle sample to be tested; in this embodiment, a glass fiber filter membrane is used, the sampling flow rate is controlled at 5 L / min, and the sampling time is 10 minutes.

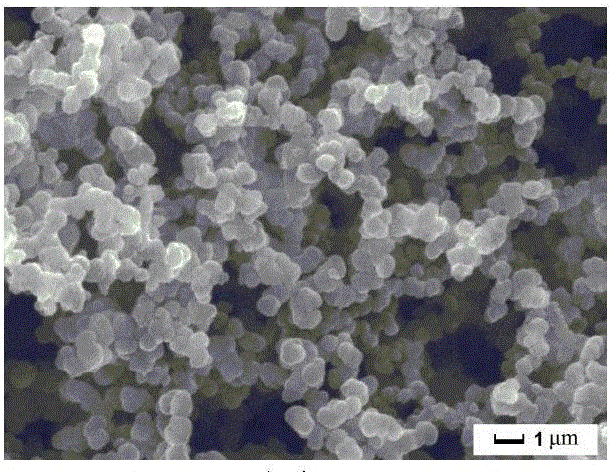

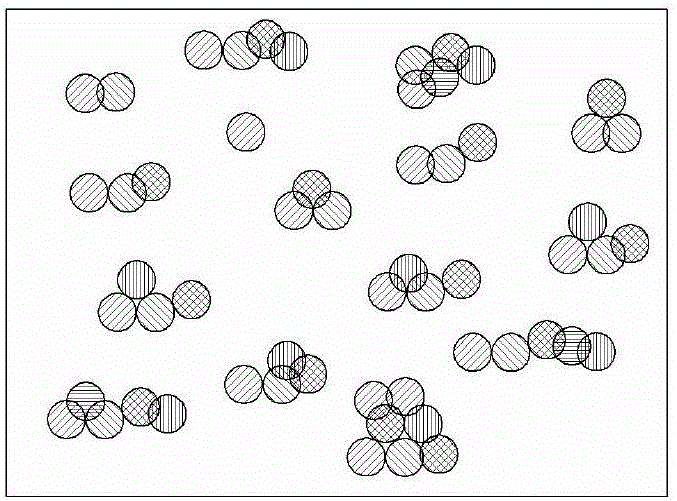

[0064] Before the dispersion treatment, the electron microscope image of engine combustion particles is as follows figure 1 As shown, the particles are agglomerated together in the form of chains, clusters, and flocs, and it is difficult to measure the particle size of a single particle.

[0065] Step 2: Dispersion treatment of the particle sample to be tested;

[0066] Use ethanol or dichloromethane solution to extract the particle sample to be tested, the amount of solvent added is 5 times the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com