Stacked encapsulation structure and manufacturing method thereof

一种层叠封装、制作方法的技术,应用在半导体/固态器件制造、半导体/固态器件零部件、半导体器件等方向,能够解决影响电连接性能、降低层叠封装结构成品率及可靠性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The package-on-package structure provided by the technical solution and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] The manufacturing method of the package-on-package structure provided by the first embodiment of the present invention includes the following steps:

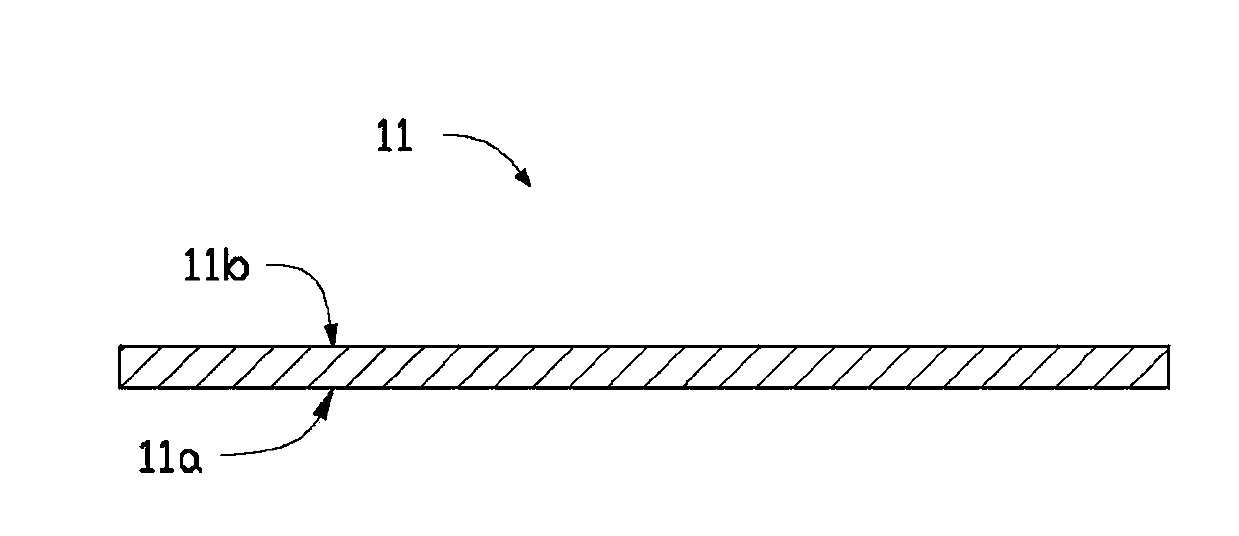

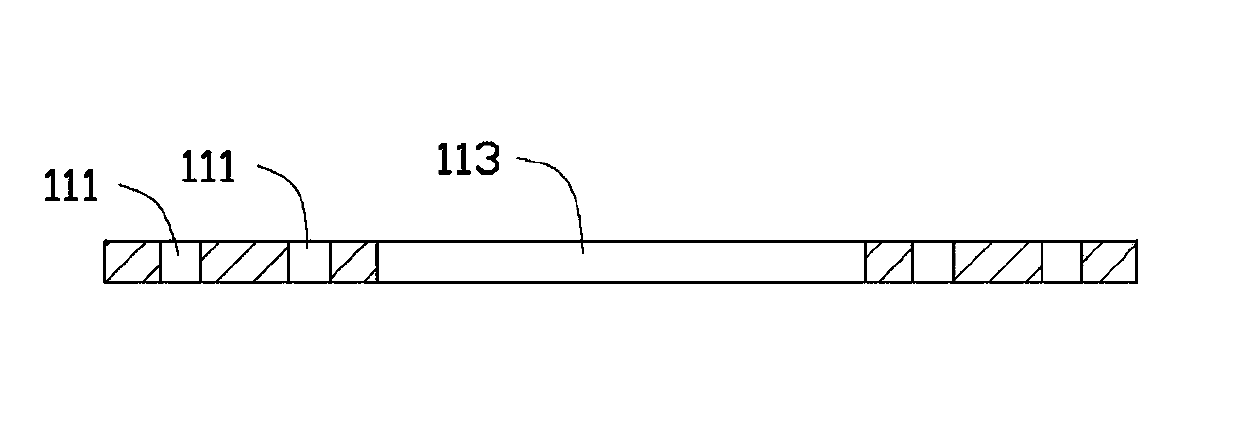

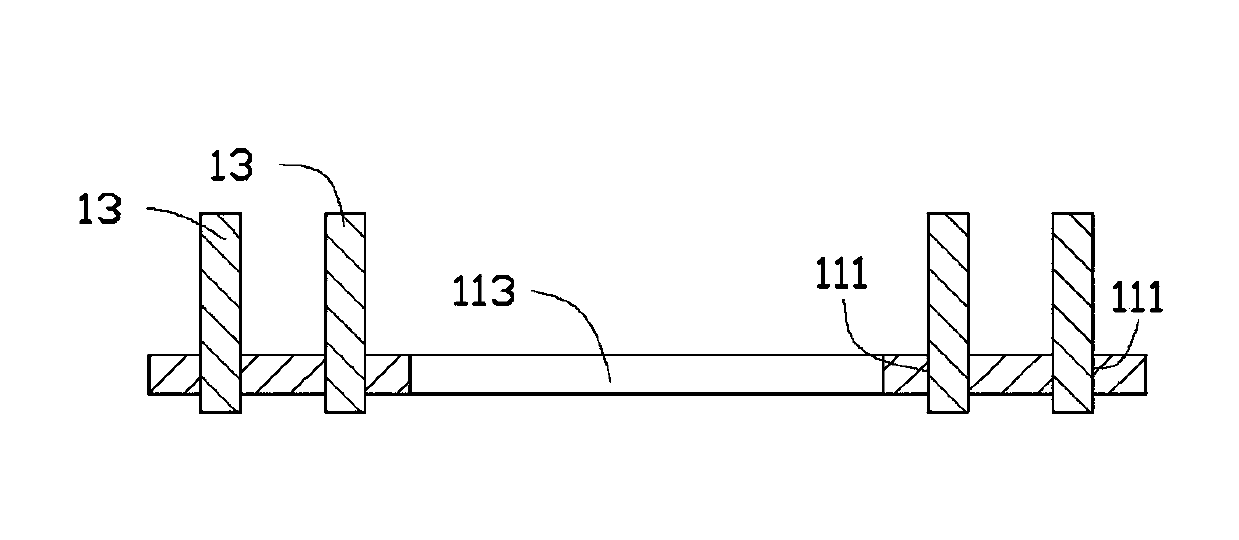

[0025] Step 1: Please also refer to Figure 1 to Figure 3, providing a connection substrate 10 . The connection substrate 10 includes a substrate body 11 and a plurality of conductive posts 13 disposed in the substrate body 11 . The substrate body 11 has a first surface 11a and a second surface 11b opposite to each other. The substrate body 11 defines a plurality of first receiving through holes 111 and a second receiving through hole 113 . Each of the plurality of first receiving through holes 111 and one second receiving through hole 113 runs through the first surface 11a and the second surface 11b, and the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com