A kind of preparation method of microporous diaphragm and microporous diaphragm

A technology of microporous membrane and body membrane, applied in electrical components, circuits, battery pack parts, etc., can solve the problems of poor heat resistance and low mechanical strength of the membrane, and achieve uniform structure, good permeability and obvious effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

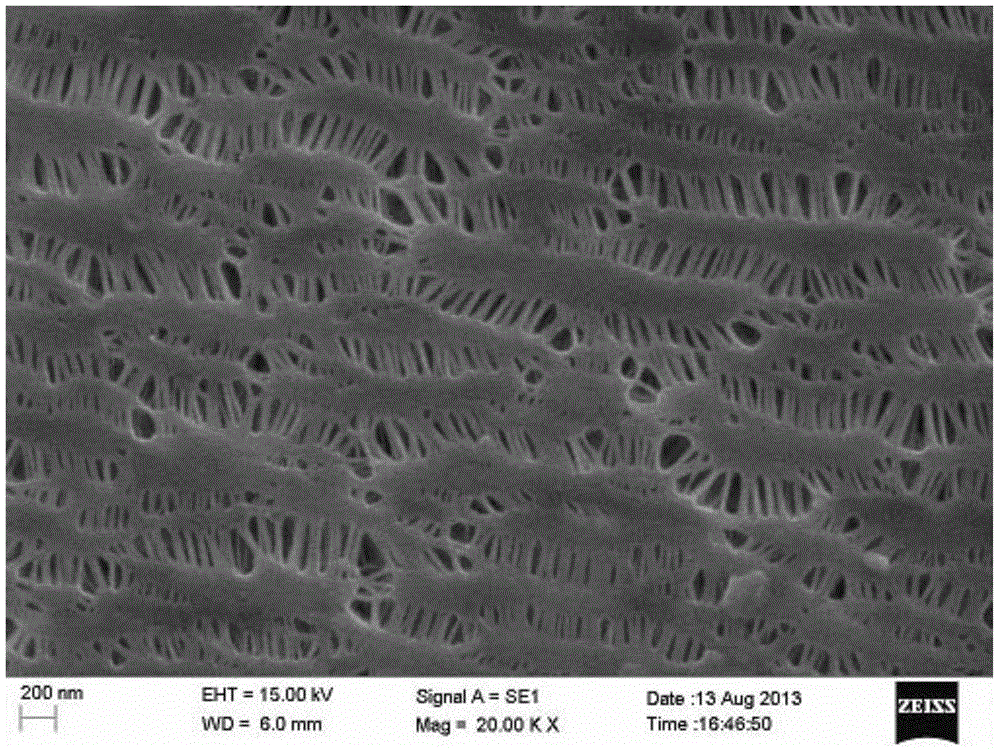

[0028] A new type of microporous diaphragm, its main raw material is polypropylene resin, auxiliary materials are plasticizer bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite and flame retardant zinc metaborate, tetrabromobutyl alkane, the thickness of the microporous membrane is 20 μm, and the porosity is 37%. The content of the main resin polypropylene is calculated as 94% by mass percentage, and the content of the plasticizer bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite and the flame retardant zinc metaborate and tetrabromobutane are as follows: The mass percentages are calculated as 2.5%, 1.5%, and 2.0%, respectively.

[0029] The method for preparing described novel microporous diaphragm comprises the steps:

[0030] 1. Stir the main polyolefin resin and auxiliary additives evenly under certain conditions with a high-speed mixing mixer, the stirring speed is 2000rpm, and the stirring time is 20min to obtain the mixture I;

[0031] 2. Add the above mi...

Embodiment 2

[0036] A new type of microporous diaphragm, its main raw material is polypropylene resin, auxiliary materials are plasticizer bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite and heat stabilizer zinc laurate, microporous membrane The thickness is 20 μm and the porosity is 42%. The content of the main resin polypropylene is 94% according to the mass percentage, and the content of the plasticizer bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite and the heat stabilizer zinc laurate are respectively calculated according to the mass percentage. 2.5% and 3.5%.

[0037] The preparation method of this example is basically the same as that of Example 1. The main changes are that in the fourth step of annealing treatment, the annealing temperature is changed to 130° C., and the annealing time is changed to 40 minutes;

Embodiment 3

[0039]A new type of microporous membrane, the main raw material is polypropylene resin, the auxiliary material is antimony trioxide (antimony white) filler and zinc laurate heat stabilizer, the thickness of the microporous membrane is 20 μm, and the porosity is 47%. The content of the main resin polypropylene is 94% by mass percentage, and the content of the filler antimony trioxide (antimony white) and the heat stabilizer zinc laurate are 2.5% and 3.5% by mass percentage, respectively.

[0040] The preparation method of this example is basically the same as that of Example 1. The main changes are that in the fourth step annealing treatment, the transverse stretch ratio is changed to 1.5, and the annealing time is changed to 60 minutes;

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com